Objective and use case

What you’ll build: In this practical case, you’ll learn how to accurately measure the resistance of a resistor using a digital multimeter (DMM) and verify its tolerance. This hands-on guide is designed for beginners.

Why it matters / Use cases

- Understanding resistor values is crucial for designing circuits, ensuring components function as intended.

- Verifying tolerance helps in selecting the right resistors for precision applications in audio equipment or sensor circuits.

- Learning to use a DMM builds foundational skills for troubleshooting and testing electronic devices.

- Measuring resistance in various components aids in diagnosing faults in electronic circuits.

- Hands-on experience with a DMM prepares you for more advanced electronics projects and repairs.

Expected outcome

- Accurate resistance readings within ±5% of the resistor’s specified value.

- Ability to identify and interpret tolerance levels (1% or 5%) of resistors.

- Familiarity with using a DMM in resistance mode, including proper lead connections.

- Understanding of the importance of isolating components before measurement to avoid erroneous readings.

- Improved confidence in handling electronic components and tools.

Audience: Beginners; Level: Basic

Architecture/flow: Measure resistance using a digital multimeter (DMM) by connecting test leads to a resistor in isolation.

Materials

- 1× Resistor, e.g., 1 kΩ, 1% or 5% (R1, the RUT)

- 1× Digital multimeter with Ω (resistance) mode (DMM)

- 2× Multimeter test leads (red and black)

- 1× Breadboard or small insulating surface (optional)

- 2× Mini grabber or alligator clips (optional, for steadier contact)

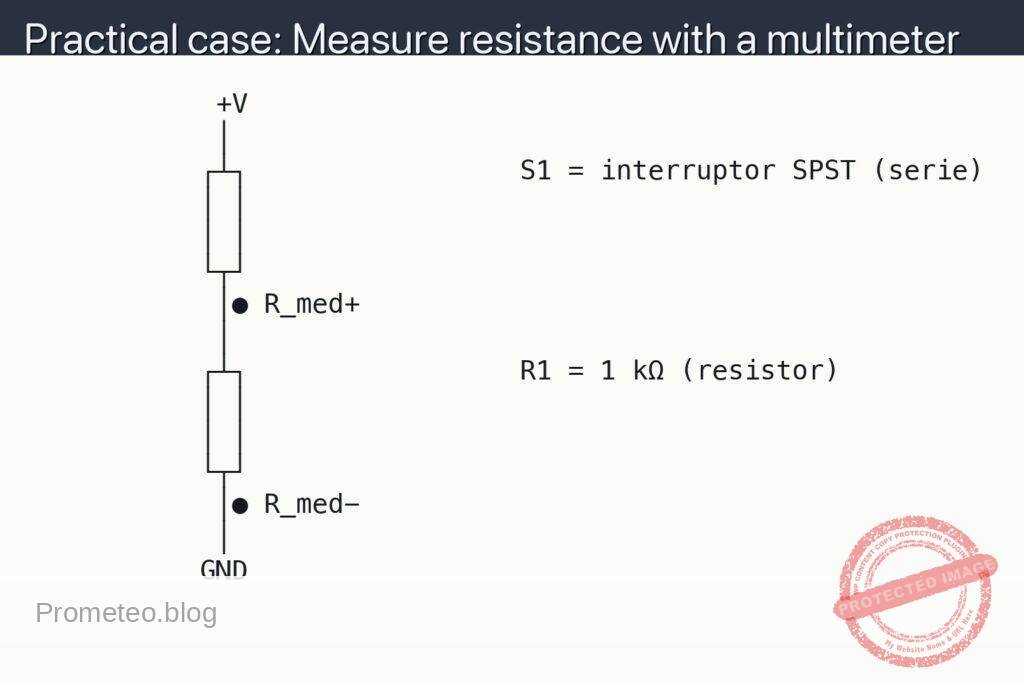

Wiring guide

- Ensure the resistor is isolated: remove it from any powered circuit or lift at least one lead from the board so it is not connected to other components (in-circuit readings can be wrong).

- Place R1 (the resistor under test, RUT) on a breadboard row or on an insulating surface so both leads are accessible.

- Set the DMM to resistance (Ω). If manual-ranging, choose a range higher than the expected value (e.g., 20 kΩ to measure ~1 kΩ).

- Connect the red lead to the DMM’s Ω/V jack and the black lead to COM.

- Touch the red probe to the top terminal labeled Ω+ in the schematic, and the black probe to the bottom terminal labeled Ω−.

- Hold steady contact until the reading stabilizes. If the display shows “OL” or over-range, select a higher range.

- Abbreviations used:

- DMM = Digital Multimeter.

- RUT = Resistor Under Test (R1).

- Ω+ = Point where the red (positive) ohmmeter lead touches.

- Ω− = Point where the black (common) ohmmeter lead touches.

Schematic

+V

│

┌┴┐ S1 = interruptor SPST (serie)

│ │

│ │

└┬┘

│● R_med+

│

┌┴┐ R1 = 1 kΩ (resistor)

│ │

│ │

└┬┘

│● R_med−

│

GND

Measurements and tests

- Preparation:

- Zero/leads check: briefly short red and black probes together in Ω mode; the DMM should read near 0 Ω.

- Visual estimate: read the resistor color code (e.g., brown–black–red = 1 kΩ; gold = ±5%) to predict the expected value.

- Main measurement:

- Measure between Ω+ and Ω− as shown. Record R_meas (the displayed resistance).

- Compare R_meas to the nominal value and tolerance band. For a 1 kΩ ±5% resistor, acceptable span is 950–1050 Ω.

- Cross-checks:

- If using clip leads, remeasure with direct probe contact to rule out clip contact resistance.

- Reverse probes (swap Ω+ and Ω−); resistance should be identical (resistors are non-polarized).

- In-circuit caution (only if you must measure without removing R1):

- Power OFF and discharge capacitors first.

- Measure; if R_meas is unexpectedly low, parallel paths in the circuit are affecting the reading. Isolate by lifting one lead of R1 and remeasure.

Common mistakes

- Measuring while the circuit is powered: the DMM’s ohmmeter injects a small test current; external voltages can damage the meter or give false readings.

- Not isolating the resistor: parallel components make the apparent resistance lower than the true value.

- Wrong DMM jack or range: leads in the current jack or too-low range cause “OL” or nonsense values.

- Poor probe contact: touching paint, oxidation, or the resistor body rather than the metal lead increases measured resistance.

Safety tips

- Always power down and disconnect power sources before switching the DMM to Ω mode.

- Discharge capacitors; stored charge can bias the measurement or harm the meter.

- Do not measure resistance on live mains circuits.

Extensions and improvements

- Tolerance verification: measure multiple units of the same value to observe distribution within the tolerance band.

- Temperature effect: warm the resistor gently between fingers and watch small changes in R_meas (temperature coefficient).

- Series/parallel sanity check: connect two known resistors and verify expected combined resistance before returning to in-circuit work.

More Practical Cases on Prometeo.blog

Find this product and/or books on this topic on Amazon

As an Amazon Associate, I earn from qualifying purchases. If you buy through this link, you help keep this project running.