Objective and use case

What you’ll build: Learn to safely scale battery voltage for ADC using a resistor divider. This guide will help you wire the components and verify the readings accurately.

Why it matters / Use cases

- Accurately measure battery voltage levels in battery-powered devices to ensure optimal performance.

- Implement voltage scaling in IoT applications using microcontrollers to monitor battery health.

- Utilize ADC readings for power management in renewable energy systems, such as solar battery chargers.

- Enable real-time voltage monitoring in remote sensors using LoRa for low-power applications.

Expected outcome

- Achieve a measurable ADC voltage reading (VADC) that accurately reflects the battery voltage (VBAT).

- Maintain a voltage scaling accuracy of ±5% for reliable battery monitoring.

- Record latencies of less than 100 ms in ADC readings for timely data updates.

- Ensure the system operates within a power consumption of less than 50 mW during measurements.

Audience: Beginners; Level: Basic

Architecture/flow: Battery > Resistor Divider > ADC > Microcontroller

Materials

- 1 × Microcontroller board with ADC input (e.g., 3.3 V ref)

- 1 × Battery (e.g., 9 V) and holder

- 1 × R1 = 220 kΩ (top of divider)

- 1 × R2 = 120 kΩ (bottom of divider)

- 1 × C1 = 100 nF ceramic (optional RC filter to ground)

- 1 × Breadboard

- 6 × Jumper wires

- 1 × Multimeter

Wiring guide

- Share ground: connect the battery negative to the microcontroller GND.

- Build the divider:

- Connect R1 from +VBAT (battery +) to the ADC tap node.

- Connect R2 from the ADC tap node to GND.

- Optional filter:

- Connect C1 from the ADC tap node to GND (in parallel with R2).

- Connect the ADC:

- Wire the ADC tap node to an ADC input pin (e.g., A0).

- Abbreviations used:

- VBAT: battery positive voltage (measure at the dot labeled VBAT).

- VADC: voltage at the ADC tap node (measure at the dot labeled VADC).

- Double-check polarity before powering:

- Battery + goes only to the top of R1; battery − to GND.

- Ensure the ADC reference (Vref) is known (e.g., 3.3 V or 5 V).

- Divider math (for later verification):

- VADC = VBAT × R2 / (R1 + R2)

- With R1 = 220 kΩ and R2 = 120 kΩ: VADC ≈ VBAT × 0.3529

- Recover battery voltage: VBAT ≈ VADC × 2.8333

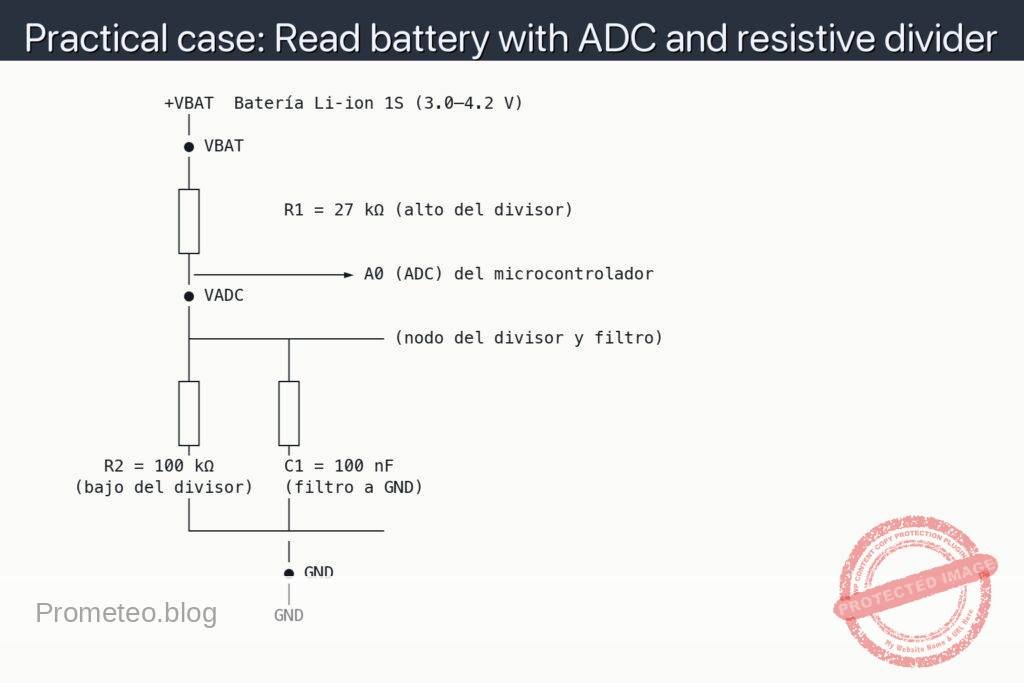

Schematic

+VBAT Batería Li‑ion 1S (3.0–4.2 V)

│

● VBAT

│

┌┴┐

│ │ R1 = 27 kΩ (alto del divisor)

│ │

└┬┘

│───────────────► A0 (ADC) del microcontrolador

● VADC

│

├─────────┬───────── (nodo del divisor y filtro)

│ │

┌┴┐ ┌┴┐

│ │ │ │

│ │ │ │

└┬┘ └┬┘

R2 = 100 kΩ C1 = 100 nF

(bajo del divisor) (filtro a GND)

│ │

└─────────┴─────────

│

● GND

│

GND

Measurements and tests

-

Pre-checks:

- Verify with the multimeter that VBAT is within expected range (e.g., ~9 V on a fresh 9 V battery).

- Confirm microcontroller GND is continuous to battery negative.

-

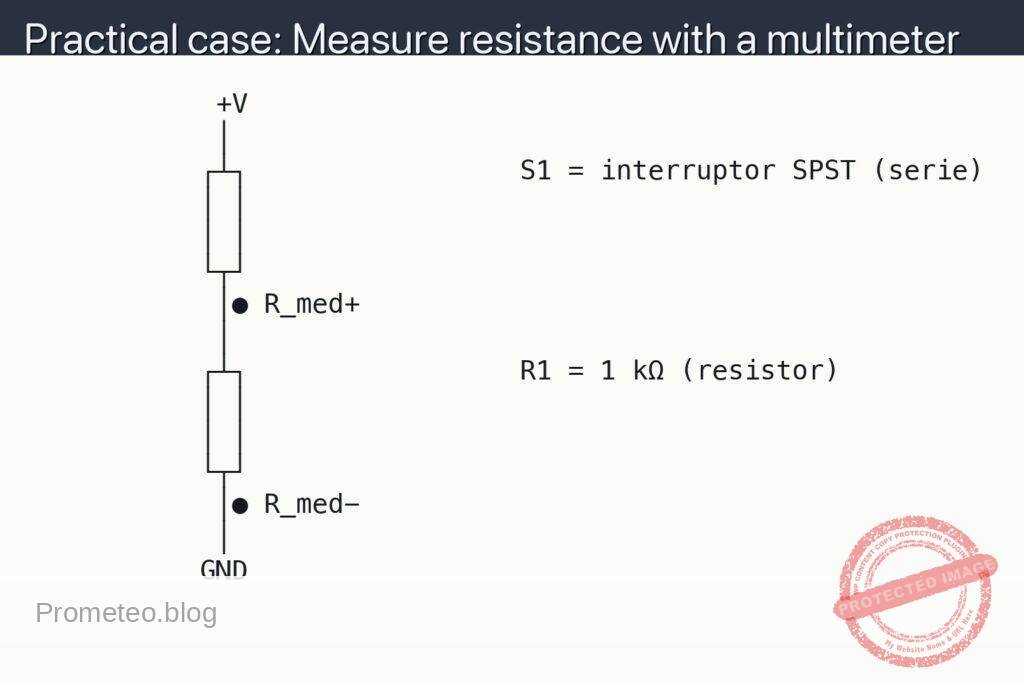

Divider verification (multimeter):

- Measure VBAT: red probe at ● VBAT, black probe at ● GND.

- Measure VADC: red probe at ● VADC, black probe at ● GND.

- Check ratio: VADC / VBAT should be close to 0.3529. If not, recheck wiring and resistor values.

-

ADC read sanity check:

- Know your ADC: VADC = ADC_count × Vref / (2^N − 1), where N is ADC resolution.

- Compute VBAT_est = VADC × (R1 + R2) / R2 ≈ VADC × 2.8333.

- Compare VBAT_est (from ADC) to VBAT (from multimeter). Expect small differences due to tolerance and ADC error.

-

Stability test (with and without C1):

- If readings bounce, fit C1 and see if VADC becomes steadier.

- Ensure ADC sampling time is adequate for the divider’s source impedance (R1 || R2 ≈ 78.3 kΩ).

Common mistakes

- Using too small resistor values, causing unnecessary battery drain.

- Forgetting common ground between battery and microcontroller.

- Exceeding ADC maximum input voltage (if the ratio is wrong).

- Placing C1 in series instead of in parallel from VADC to GND.

Safety notes

- Never connect the battery directly to the ADC pin.

- Double-check polarity before powering.

- If measuring higher-voltage packs (e.g., >12 V), recalculate resistor values to keep VADC ≤ Vref.

Improvements

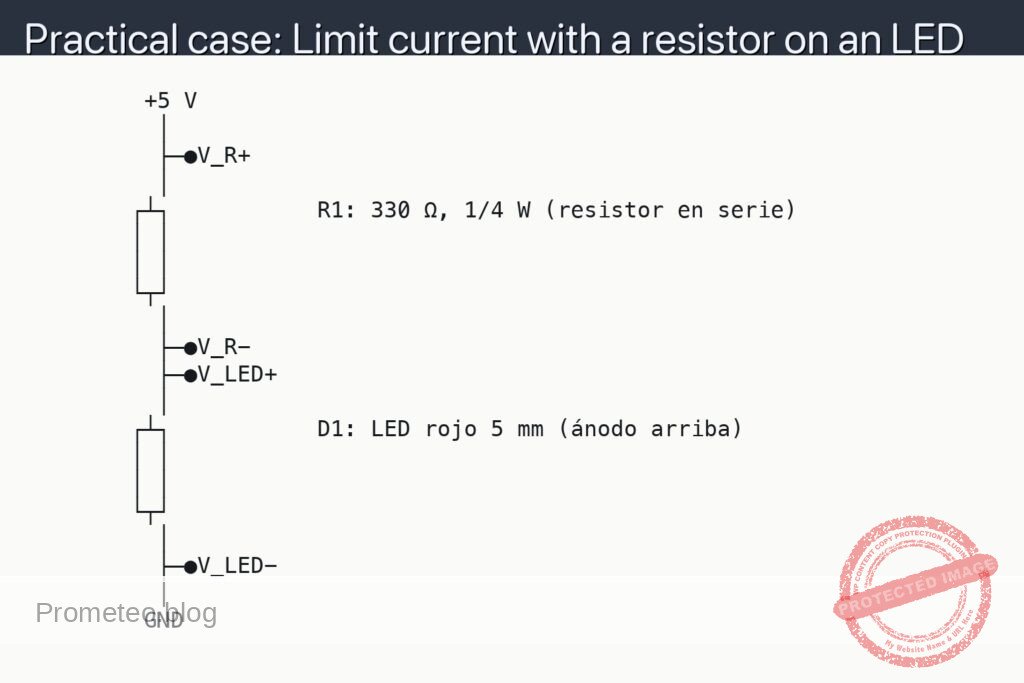

- Add a series 1 kΩ resistor from the VADC node to the ADC pin for ESD/overcurrent protection.

- Add a 3.6 V TVS diode or clamp to protect the ADC from transients.

- Calibrate in firmware using measured R1 and R2 values and ADC reference for higher accuracy.

- Use lower-tolerance resistors (e.g., 1%) to reduce scaling error.

More Practical Cases on Prometeo.blog

Find this product and/or books on this topic on Amazon

As an Amazon Associate, I earn from qualifying purchases. If you buy through this link, you help keep this project running.