Objective and Use Case

What you will build: An electromechanical doorbell with a coil that attracts a metal hammer to strike a small bell‑type plate, powered by a 9–12 V DC supply.

What it is used for

- Simulating how a classic home doorbell works in projects and school fairs.

- Demonstrating how an inductor converts electrical energy (9–12 V, 200–400 mA) into visible and audible mechanical motion.

- Implementing a low‑voltage alert in scale models (for example, when opening a door in a scale house).

- Showing the effect of self‑induction and the need for a protection diode in parallel with the coil.

- Practicing the safe control of inductive loads using a transistor as a power stage with a low‑current control signal.

Expected Result

- The coil is energized with ≈ 9–12 V DC and generates a magnetic field capable of attracting the hammer clearly and repeatedly.

- Current consumption of the coil between 200–400 mA, measured in series (I_COIL) without overheating the coil or the transistor.

- Collector‑emitter voltage of the transistor (V_CE) in the range of 0.2–0.4 V when the coil is activated, indicating proper saturation.

- Voltage on the coil (V_COIL) close to the supply voltage when the transistor is cut off and the doorbell is off.

- Audible strike of the plate when pressing the button, with no damage to components thanks to the protection diode and proper current sizing.

Target audience: High school students, beginner makers, and technology teachers; Level: Beginner–intermediate in basic electronics.

Architecture/flow: DC supply (9–12 V) → power transistor that switches the coil → coil that generates the magnetic field and moves the hammer → flyback diode to absorb voltage spikes from self‑induction → push button or logic signal that drives the transistor base → hammer strikes the plate, producing the doorbell sound.

Materials

- 1 × Regulated 9–12 V DC power supply (or good‑quality 9 V battery; preferably a pack of 8×AA 1.5 V).

- 1 × Doorbell coil or small electromagnet (typical DC resistance 20–60 Ω).

- 1 × General‑purpose NPN transistor (e.g., 2N2222 or BC337).

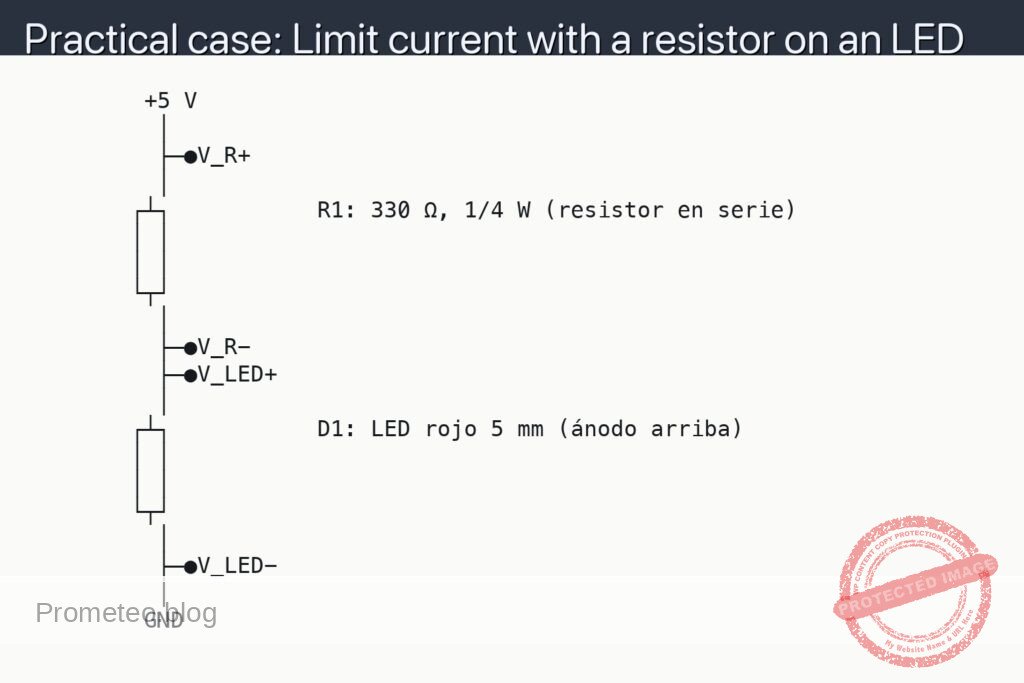

- 1 × Base resistor [R1] of 4.7 kΩ (for the transistor).

- 1 × Protection diode [D1] 1N4007 (or similar rectifier).

- 1 × Normally open push button.

- 1 × Metal plate or small bell (the doorbell “gong”).

- 1 × Metal piece or screw as a movable core / hammer (or flexible metal tongue).

- 1 × Protoboard (breadboard) or mounting base.

- Several × Breadboard wires (jumpers).

- 1 × Digital multimeter (to measure voltages and currents).

- 1 × Simple mechanical support (wood/cardboard) to fix the coil and bell (optional but recommended).

Wiring Guide

Treat this section as the official wiring specification. The schematic will follow these connections exactly.

- Power connections:

- Connect the positive terminal of the 9–12 V supply to the node labeled

+V. -

Connect the negative terminal of the supply to the node labeled

GND. -

Coil (inductor) connection:

- Connect one end of the doorbell coil to the

+Vnode. -

Connect the other end of the coil to node

VC(transistor collector). -

Protection diode across the coil:

- Connect the cathode of [D1] 1N4007 (end marked with a band) to node

+V. - Connect the anode of [D1] to node

VC. -

That is, the diode is in parallel with the coil but oriented opposite to the normal polarity of the supply.

-

NPN transistor (switching stage):

- Connect the collector of the NPN transistor to node

VC. - Connect the emitter of the NPN transistor to node

GND. -

Connect the base of the NPN transistor to node

VB. -

Base resistor and push button:

- Connect one end of resistor [R1] 4.7 kΩ to node

+V. - Connect the other end of [R1] to node

VBTN. - Connect one terminal of the push button to node

VBTN. - Connect the other terminal of the push button to node

VB. -

Optionally connect a 100 kΩ pull‑down resistor [R2] between node

VBandGND(if you have one; it helps keep the transistor fully off when not pressed).- One end of [R2] to node

VB. - The other end of [R2] to node

GND.

- One end of [R2] to node

-

Measurement node:

- Node

VCwill be the point where you measure collector voltage (V_CE) with respect toGND. - Node

VBwill be the point where you measure base voltage (V_B) with respect toGND. - You will measure coil current (I_COIL) by inserting the multimeter in series between

+Vand the coil during tests.

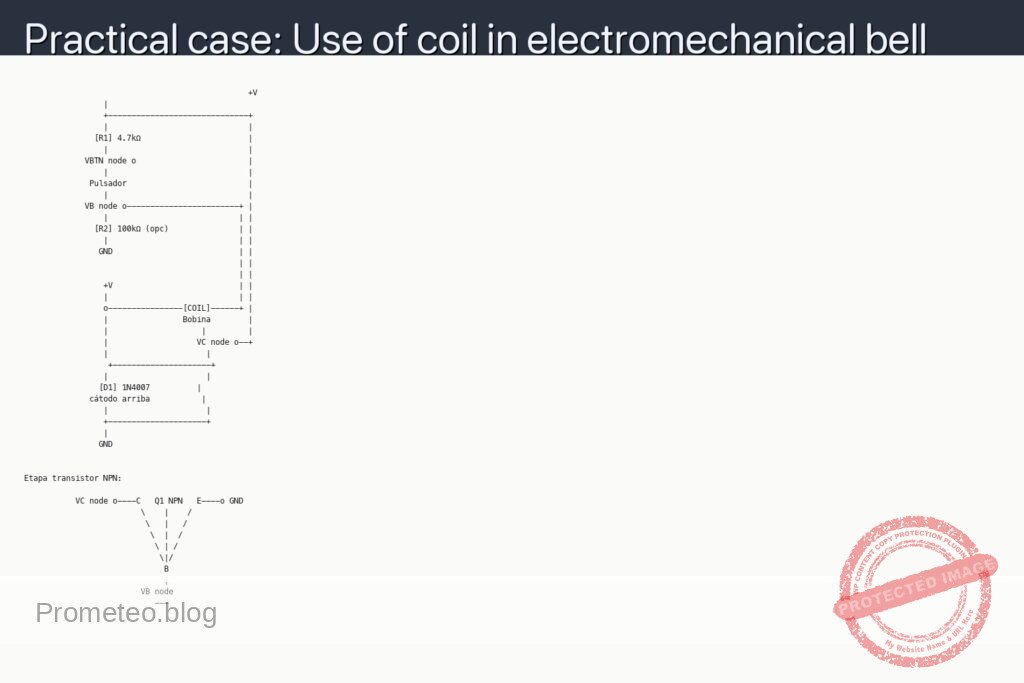

Schematic

+V

|

+------------------------------+

| |

[R1] 4.7kΩ |

| |

VBTN node o |

| |

Pulsador |

| |

VB node o------------------------+ |

| | |

[R2] 100kΩ (opc) | |

| | |

GND | |

| |

| |

+V | |

| | |

o----------------[COIL]------+ |

| Bobina |

| | |

| VC node o--+

| |

+---------------------+

| |

[D1] 1N4007 |

cátodo arriba |

| |

+---------------------+

|

GND

Etapa transistor NPN:

VC node o----C Q1 NPN E----o GND

\ | /

\ | /

\ | /

\ | /

\|/

B

|

VB node

---

Measurements and Tests

-

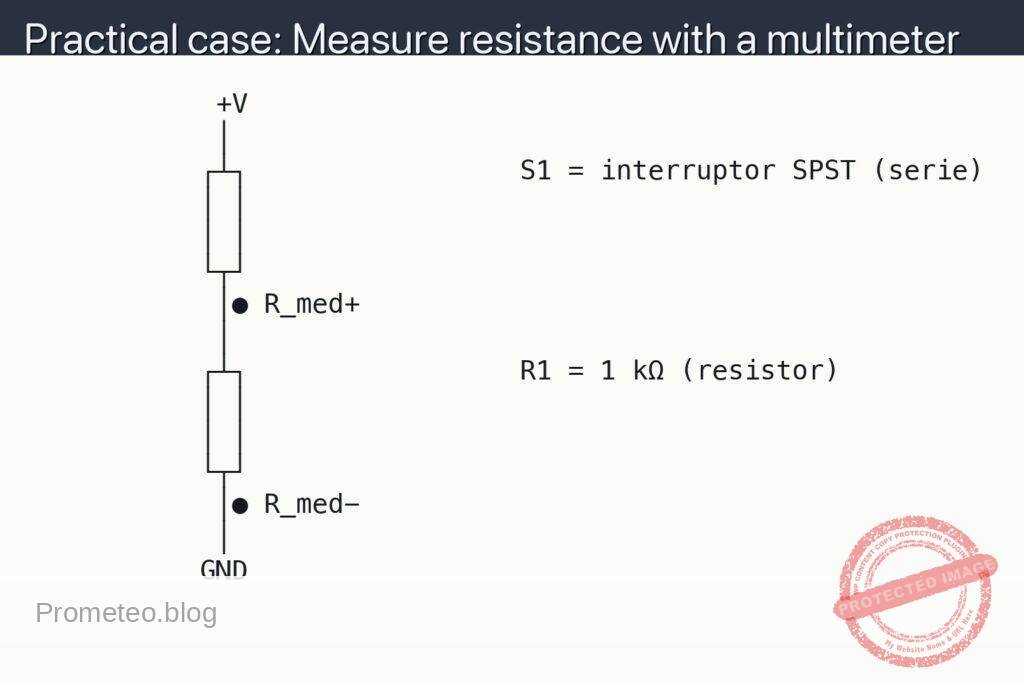

Basic verification without transistor (coil only):

- With the supply disconnected, measure the DC resistance of the coil with the multimeter in ohmmeter mode (typical value between 20–60 Ω).

- Calculate the expected current I_COIL = V / R_COIL (for example, for 12 V and 40 Ω → I_COIL ≈ 0.3 A) to confirm that your supply can provide it.

-

Supply voltage measurement:

- Set the multimeter to DC voltmeter mode.

- Measure the voltage between

+VandGNDto ensure that you actually have 9–12 V (red probe to +V, black probe to GND).

-

Measuring V_B (base voltage, VB):

- V_B means “voltage at the transistor base with respect to GND”.

- Place the black multimeter probe on

GNDand the red one on nodeVB. - With the button not pressed, V_B should be close to 0 V (especially if you use [R2] as a pull‑down resistor).

- With the button pressed, V_B should rise to about 0.7–1 V (typical of a conducting base‑emitter junction).

-

Measuring V_CE (collector‑emitter voltage):

- V_CE means “voltage between the collector and emitter of the transistor”.

- Place the black probe on

GND(emitter) and the red on nodeVC(collector). - With the button not pressed, V_CE ≈ supply voltage (+V), because the coil does not conduct and the transistor is cut off.

- With the button pressed, V_CE should drop to a low value (≈ 0.2–0.4 V) if the transistor saturates correctly, indicating that most of the voltage is now across the coil.

-

Measuring I_COIL (coil current):

- I_COIL means “current flowing through the coil”.

- Put the multimeter in DC ammeter mode (appropriate range, for example 1 A or 400 mA as expected).

- Disconnect the wire going from

+Vto the coil and instead connect the multimeter in series:- Red multimeter probe to node

+V. - Black multimeter probe to the end of the coil that previously went to

+V.

- Red multimeter probe to node

- Press the button briefly and read the current: it should be close to the calculated value (for example, 0.2–0.4 A). Do not hold it down for too long if the transistor gets hot.

-

Mechanical operation tests:

- Make sure the moving part (hammer or tongue) is well aligned: when the coil is energized, it should move toward the metal plate or bell.

- Press the button repeatedly: each time you should hear a click or a small “ding”.

- If there is no sound, try adjusting the distance between the coil core and the moving part (too far and it will not move; too close and it may stick).

Key Concepts About the Coil in This Doorbell

- Inductor as an electromagnet:

- The coil is an inductor: a set of wire turns that, when current flows, generates a magnetic field.

-

This magnetic field attracts ferromagnetic metal parts (iron, steel), which is what moves the doorbell hammer.

-

Self‑induction and protection diode:

- When you interrupt the coil current (by releasing the button), the magnetic field collapses.

- This rapid change in the field induces an opposite voltage (called “induced voltage” or “inductive spike”) that can be very high.

-

Diode [D1], placed in reverse parallel across the coil, provides a safe path for this induced current and limits the overvoltage, protecting the transistor.

-

Using the transistor as an electronic switch:

- The NPN transistor acts here as a switch controlled by base current.

- When the base receives current through [R1] (button pressed), the transistor conducts and allows current to flow through the coil.

- When the base is at 0 V (button released), the transistor switches off and the coil is de‑energized.

Common Mistakes and How to Avoid Them

- Forgetting the protection diode [D1]:

- Without [D1], the transistor can be damaged by coil voltage spikes.

-

Symptoms: transistor getting very hot or failing suddenly.

-

Reversed diode polarity:

- If you connect the diode the wrong way around (anode to +V, cathode to VC), the coil will not activate because the diode will cause a short circuit (with high current).

-

Remember: diode band (cathode) toward

+V, unmarked end (anode) towardVC. -

Transistor pins swapped:

- Different models (2N2222, BC337, etc.) have different pin layouts (E‑B‑C).

-

Always check the datasheet to know which pin is collector, base, and emitter.

-

AC doorbell coil used with DC without checking:

- Some commercial doorbells are designed for 230 V AC and not for low‑voltage DC.

- Always use a coil/electromagnet suitable for 9–12 V DC or a low‑voltage doorbell.

Possible Improvements and Extensions

- Automatic (repeating) doorbell:

- Add a mechanical contact that opens and closes due to the hammer’s own motion (classic doorbell style), so it makes a continuous “drrrrring” while you keep the button pressed.

-

This can be implemented with a flexible tongue that touches a contact when at rest and releases it when attracted by the coil.

-

Control from a microcontroller:

- Replace the push button with a digital output from an Arduino or similar.

-

Keep the same power stage with transistor and diode so as not to overload the microcontroller output.

-

Waveform measurement with an oscilloscope:

- If you have an oscilloscope, observe the voltage waveform at node

VCwhen you cut the current. -

You will see how the diode clips the inductive spike and limits the voltage.

-

Doorbell optimization:

- Try coils with different numbers of turns or different cores (iron screw, solid bolt, laminated core).

- Adjust the distance between the coil and the moving piece to maximize force and sound without it getting stuck.

With this practical project you will have seen, in a very tangible way, how an inductor works as an electromagnet, why it generates voltage spikes when disconnected, and how to protect the circuit with a diode, all applied to something very everyday: an electromechanical doorbell.

More Practical Cases on Prometeo.blog

Find this product and/or books on this topic on Amazon

As an Amazon affiliate, I earn from qualifying purchases. If you buy through this link, you help support this project.