Level: Basic. Learn how to isolate a low-power control signal from a high-power motor circuit using an electromagnetic relay.

Objective and use case

In this practical case, you will build a circuit that utilizes a small pushbutton and a relay to control a high-current DC motor. The relay acts as an electromagnetic switch, allowing the low-power control side to activate the high-power load side without direct electrical connection between the distinct power rails (if separate grounds are used) or simply to handle currents exceeding the switch’s rating.

Why it is useful:

* Automotive systems: Used in starter motors where a small ignition key switch triggers a massive solenoid (relay) to crank the engine.

* Industrial automation: Allows low-voltage PLCs (24 V) to switch high-voltage AC or DC motors (110 V/220 V) safely.

* Safety isolation: Keeps high voltages away from the user interface (buttons and switches).

* Component protection: Prevents burning out delicate switches by offloading the high current switching to the relay contacts.

Expected outcome:

* When the pushbutton is pressed, the relay makes an audible «click.»

* The DC motor starts spinning immediately upon the click.

* Voltage across the relay coil measures 5 V (or rated control voltage).

* The flyback diode protects the switch from high-voltage spikes when the button is released.

Target audience and level: Students and hobbyists understanding basic electromechanical switching (Basic).

Materials

- V1: 5 V DC voltage source, function: Control circuit power supply.

- V2: 12 V DC voltage source, function: Motor (Power) circuit supply.

- S1: Momentary Pushbutton (Normally Open), function: Control switch.

- K1: SPDT Relay (5 V Coil), function: Electromechanical isolation and switching.

- D1: 1N4007 Diode, function: Flyback/Freewheeling diode for coil protection.

- M1: 12 V DC Motor, function: High-power load.

Wiring guide

This guide uses SPICE-friendly node names to define the connections. The nodes are: V_CTRL (5 V), V_PWR (12 V), COIL_IN, MOTOR_IN, and 0 (Ground).

- V1 (Positive): Connects to node

V_CTRL. - V1 (Negative): Connects to node

0. - V2 (Positive): Connects to node

V_PWR. - V2 (Negative): Connects to node

0. - S1: Connects between node

V_CTRLand nodeCOIL_IN. - K1 (Coil terminal A): Connects to node

COIL_IN. - K1 (Coil terminal B): Connects to node

0. - D1 (Cathode/Striped side): Connects to node

COIL_IN. - D1 (Anode): Connects to node

0. - K1 (Common/COM Contact): Connects to node

V_PWR. - K1 (Normally Open/NO Contact): Connects to node

MOTOR_IN. - M1 (Positive): Connects to node

MOTOR_IN. - M1 (Negative): Connects to node

0.

Note: In a physical application requiring galvanic isolation, the ground 0 for the control side (V1) and the power side (V2) would be kept separate. For this basic simulation model, they share a common reference.

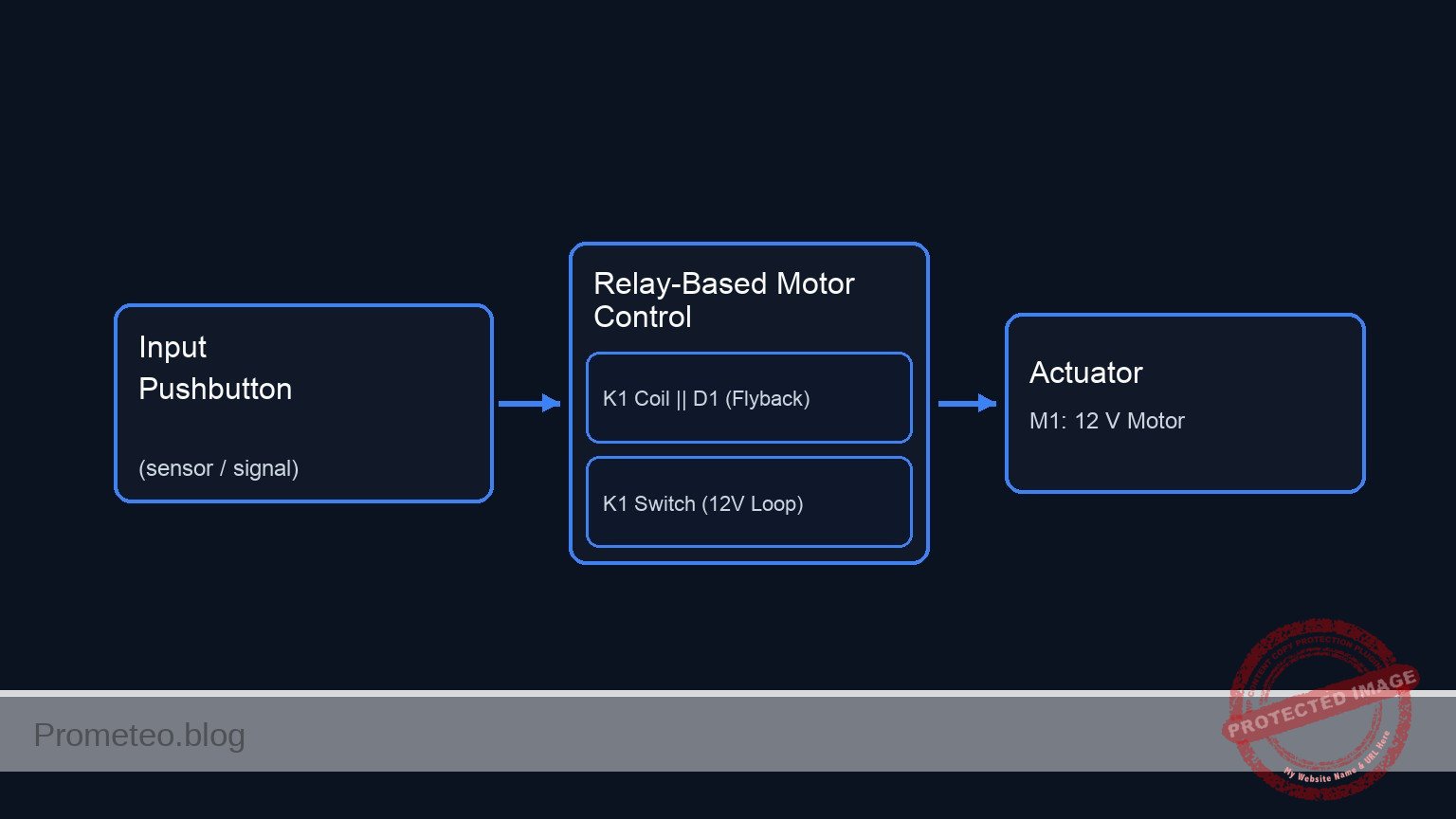

Conceptual block diagram

Schematic

+---------------------------------------------------------------------------------------------------------+

| DC MOTOR CONTROL WITH RELAY (UNIFIED DIAGRAM) |

+---------------------------------------------------------------------------------------------------------+

(High Power Loop: 12 V)

[ V2: 12 V Source ] --(Node: V_PWR)--> [ K1: Relay Switch (COM->NO) ] --(Node: MOTOR_IN)--> [ M1: 12 V Motor ] --> [ GND ]

^

|

(Magnetic Link)

|

(Control Loop: 5 V) |

[ V1: 5 V Source ] --(Node: V_CTRL)--> [ S1: Pushbutton ] --(Node: COIL_IN)--> [ Parallel: K1 Coil || D1 (Rev) ] --> [ GND ]

+---------------------------------------------------------------------------------------------------------+

| LEGEND & NOTES: |

| --> : Signal/Power Flow |

| || : Components in Parallel (Coil and Diode share Node COIL_IN and GND) |

| Rev : Diode D1 is Reverse Biased (Cathode to COIL_IN, Anode to GND) to suppress flyback voltage. |

| Link : The current in the Control Loop generates the magnetic field to close the Switch in the Power Loop. |

+---------------------------------------------------------------------------------------------------------+

Measurements and tests

Follow these steps to validate your circuit assembly:

-

Coil Voltage Check:

- Set your multimeter to DC Voltage (20 V range).

- Connect probes across the relay coil terminals (

COIL_INand0). - Press S1. The reading should jump from 0 V to approx. 5 V.

-

Audible Confirmation:

- Press and release S1. Listen for the mechanical «click» of the relay armature moving. If you do not hear it, the coil is not energizing.

-

Load Voltage Verification:

- Connect the multimeter across the motor terminals.

- Press S1. The multimeter should read approx. 12 V (voltage of V2) and the motor should spin.

- Release S1. The voltage should drop to 0 V and the motor should coast to a stop.

-

Flyback Diode Test (Advanced):

- Without D1, monitoring

COIL_INwith an oscilloscope would reveal a large negative voltage spike when S1 is released. With D1 installed, this spike is clamped to approx. -0.7 V, protecting S1.

- Without D1, monitoring

SPICE netlist and simulation

Reference SPICE Netlist (ngspice) — excerptFull SPICE netlist (ngspice)

* Practical case: DC motor control with relay and pushbutton

* --- Models ---

* Generic Pushbutton Switch Model (Voltage Controlled)

.model SW_PB SW(Vt=2.5 Vh=0.1 Ron=0.01 Roff=10Meg)

* Relay Contact Switch Model (Controlled by Coil Voltage)

.model SW_RELAY SW(Vt=3.5 Vh=0.2 Ron=0.05 Roff=10Meg)

* 1N4007 Diode Model

.model D1N4007 D(IS=7.07e-9 RS=0.034 N=1.7 BV=1000 IBV=5e-6 CJO=1e-11 TT=1e-7)

* --- Power Supplies ---

* V1: Control Circuit Power (5V)

V1 V_CTRL 0 DC 5

* V2: Motor Circuit Power (12V)

V2 V_PWR 0 DC 12

* --- Control Circuit (Input) ---

* S1: Pushbutton.

* Modeled as a voltage-controlled switch driven by a PULSE source (V_ACT)

* to simulate the physical act of pressing the button.

* ... (truncated in public view) ...Copy this content into a .cir file and run with ngspice.

* Practical case: DC motor control with relay and pushbutton

* --- Models ---

* Generic Pushbutton Switch Model (Voltage Controlled)

.model SW_PB SW(Vt=2.5 Vh=0.1 Ron=0.01 Roff=10Meg)

* Relay Contact Switch Model (Controlled by Coil Voltage)

.model SW_RELAY SW(Vt=3.5 Vh=0.2 Ron=0.05 Roff=10Meg)

* 1N4007 Diode Model

.model D1N4007 D(IS=7.07e-9 RS=0.034 N=1.7 BV=1000 IBV=5e-6 CJO=1e-11 TT=1e-7)

* --- Power Supplies ---

* V1: Control Circuit Power (5V)

V1 V_CTRL 0 DC 5

* V2: Motor Circuit Power (12V)

V2 V_PWR 0 DC 12

* --- Control Circuit (Input) ---

* S1: Pushbutton.

* Modeled as a voltage-controlled switch driven by a PULSE source (V_ACT)

* to simulate the physical act of pressing the button.

* Wiring: Connects V_CTRL to COIL_IN.

V_ACT ACT_NODE 0 PULSE(0 5 10m 1u 1u 245m 1s)

S1 V_CTRL COIL_IN ACT_NODE 0 SW_PB

* K1: Relay Coil

* Wiring: Coil Terminal A to COIL_IN, Coil Terminal B to 0.

* Modeled as Inductor + Resistor in series.

R_K1_COIL COIL_IN K1_INT 60

L_K1_COIL K1_INT 0 100m

* D1: Flyback Diode

* Wiring: Cathode to COIL_IN, Anode to 0.

* SPICE Syntax: D

D1 0 COIL_IN D1N4007

* --- Power Circuit (Output) ---

* K1: Relay Contact (Switch)

* Wiring: Common (COM) to V_PWR, Normally Open (NO) to MOTOR_IN.

* Controlled by the voltage at node COIL_IN.

S_K1_SW V_PWR MOTOR_IN COIL_IN 0 SW_RELAY

* M1: DC Motor

* Wiring: Positive to MOTOR_IN, Negative to 0.

* Modeled as an RL load (Resistance + Inductance).

R_M1 MOTOR_IN M1_INT 20

L_M1 M1_INT 0 10m

* --- Analysis Directives ---

.op

.tran 0.1m 250m

* --- Output Printing ---

* Must define INPUT (COIL_IN) and OUTPUT (MOTOR_IN)

.print tran V(COIL_IN) V(MOTOR_IN) V(ACT_NODE) I(L_M1)

.end Simulation Results (Transient Analysis)

Show raw data table (2535 rows)

Index time v(coil_in) v(motor_in) v(act_node) l_m1#branch 0 0.000000e+00 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 1 1.000000e-06 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 2 2.000000e-06 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 3 4.000000e-06 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 4 8.000000e-06 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 5 1.600000e-05 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 6 3.200000e-05 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 7 6.400000e-05 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 8 1.280000e-04 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 9 2.280000e-04 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 10 3.280000e-04 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 11 4.280000e-04 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 12 5.280000e-04 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 13 6.280000e-04 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 14 7.280000e-04 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 15 8.280000e-04 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 16 9.280000e-04 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 17 1.028000e-03 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 18 1.128000e-03 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 19 1.228000e-03 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 20 1.328000e-03 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 21 1.428000e-03 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 22 1.528000e-03 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 23 1.628000e-03 2.999953e-05 2.399995e-05 0.000000e+00 1.199998e-06 ... (2511 more rows) ...

Common mistakes and how to avoid them

-

Omitting the Flyback Diode (D1):

- Error: Leaving out the diode across the relay coil.

- Consequence: The collapsing magnetic field generates a high-voltage spike (back EMF) that can arc across the switch contacts or destroy transistor drivers in future circuits.

- Solution: Always install a diode in reverse bias (Cathode to positive) across inductive loads.

-

Using the Wrong Relay Contacts (NC vs NO):

- Error: Connecting the motor to the Normally Closed (NC) pin instead of Normally Open (NO).

- Consequence: The motor runs continuously when the button is not pressed and stops when it is pressed.

- Solution: Identify the NO pin using the datasheet or a continuity test before soldering.

-

Mixing Power Rails:

- Error: Connecting the 12 V motor supply directly to the 5 V coil.

- Consequence: The relay coil will overheat and likely burn out due to over-voltage.

- Solution: Ensure the coil voltage matches the control supply (V1) and the contact rating matches the motor supply (V2).

Troubleshooting

-

Symptom: Relay clicks, but motor does not run.

- Cause: Burnt relay contacts or loose wire between COM/NO and the motor.

- Fix: Check continuity across COM and NO while the relay is held active.

-

Symptom: Relay does not click when S1 is pressed.

- Cause: Coil wiring error or S1 is faulty.

- Fix: Measure voltage at the coil terminals while pressing S1. If 0 V, check S1.

-

Symptom: Circuit resets or sparks occur at S1.

- Cause: Lack of flyback diode causing arcing.

- Fix: Install D1 immediately across the coil terminals.

Possible improvements and extensions

- Transistor Driver: Replace the direct pushbutton connection with an NPN transistor (e.g., 2N2222) to control the relay using a weak signal from an Arduino or microcontroller.

- Self-Latching Circuit: Add a second relay contact or wire the relay in a «latching» configuration with a separate «Stop» button (NC), so you don’t have to hold S1 to keep the motor running.

More Practical Cases on Prometeo.blog

Find this product and/or books on this topic on Amazon

As an Amazon Associate, I earn from qualifying purchases. If you buy through this link, you help keep this project running.