Level: Basic – Understand how to use two SPDT relays to change polarity and direction of a DC motor.

Objective and use case

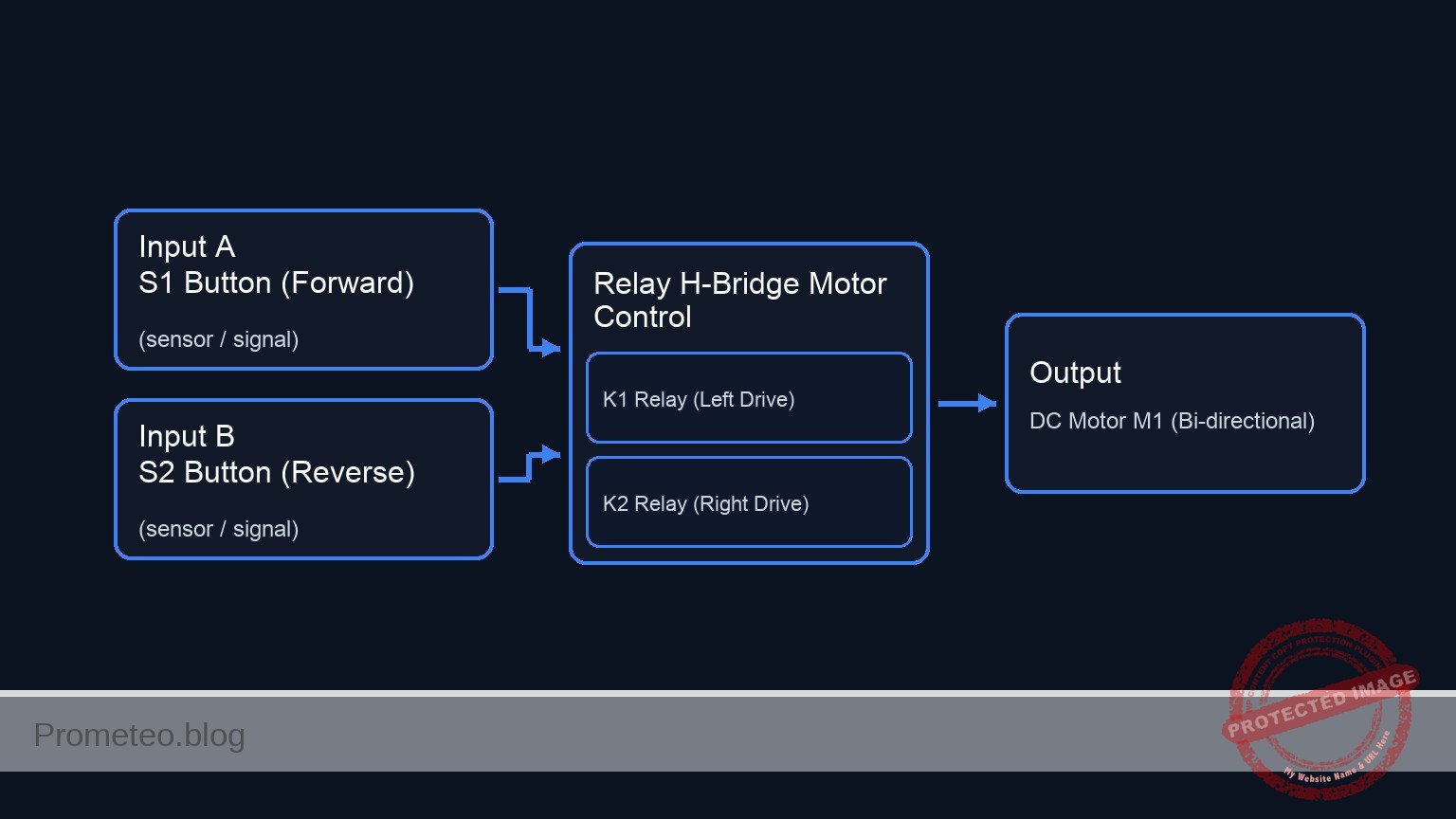

In this case, you will build a relay-based H-bridge circuit to control a DC motor. By using two Single Pole Double Throw (SPDT) relays, you will be able to drive the motor clockwise, counter-clockwise, or brake it using simple pushbuttons.

- Real-world scenarios:

- Automotive Power Windows: Reversing the motor to raise or lower the glass.

- Robotics: Controlling wheel direction for forward and backward movement.

- Industrial Conveyors: Changing the direction of a belt to route products.

-

Motorized Curtains: Opening and closing mechanisms.

-

Expected outcome:

- Idle State: When no buttons are pressed, the motor terminals are grounded (0 V difference), resulting in a dynamic brake (motor stops).

- Forward State: Pressing Button A applies +5 V to the motor; it spins Clockwise (CW).

- Reverse State: Pressing Button B applies -5 V (polarity swap) to the motor; it spins Counter-Clockwise (CCW).

- Braking/Safety: If both buttons are pressed simultaneously, both motor terminals connect to VCC, resulting in 0 V difference and the motor remains stopped.

Target audience: Hobbyists and students getting started with electromechanical control.

Materials

- V1: 5 V DC Power Supply, function: Main energy source.

- M1: 5 V DC Motor, function: The actuator to be controlled.

- K1: 5 V SPDT Relay, function: Controls the «Positive» side of the motor.

- K2: 5 V SPDT Relay, function: Controls the «Negative» side of the motor.

- S1: Momentary Pushbutton (NO), function: Activates Relay K1 (Forward).

- S2: Momentary Pushbutton (NO), function: Activates Relay K2 (Reverse).

- D1: 1N4007 Diode, function: Flyback protection for K1 coil.

- D2: 1N4007 Diode, function: Flyback protection for K2 coil.

Wiring guide

This guide uses node names to describe connections.

Nodes: VCC (5 V Supply), 0 (Ground), COIL_A, COIL_B, MOT_A, MOT_B.

- Power Supply:

- V1 (+): Connects to node

VCC. -

V1 (-): Connects to node

0. -

Control Circuit (Coils):

- S1: Connects between

VCCandCOIL_A. - K1 (Coil): Connects between

COIL_Aand0. - D1: Cathode to

COIL_A, Anode to0(Protects against inductive spikes). - S2: Connects between

VCCandCOIL_B. - K2 (Coil): Connects between

COIL_Band0. -

D2: Cathode to

COIL_B, Anode to0. -

Power Circuit (Motor Drive):

- K1 (Normally Open – NO): Connects to

VCC. - K1 (Normally Closed – NC): Connects to

0. - K1 (Common – COM): Connects to node

MOT_A. - K2 (Normally Open – NO): Connects to

VCC. - K2 (Normally Closed – NC): Connects to

0. - K2 (Common – COM): Connects to node

MOT_B. - M1: Connects between

MOT_AandMOT_B.

Conceptual block diagram

Schematic

+-------------------------------------------------------------------------+

| DC MOTOR REVERSING CIRCUIT (H-BRIDGE) |

+-------------------------------------------------------------------------+

[ CONTROL SUBSYSTEM ] [ POWER SUBSYSTEM ]

(Forward Input) (Left Side Drive)

VCC --> [ S1 Button ] VCC (NO)

| |

v v

[ Node: COIL_A ] [ K1 Switch (COM) ] --(MOT_A)--+

| [ (Relay 1) ] |

+--> [ K1 Coil || D1 ] --> GND ^ |

| (D1 is Reverse Biased) | |

| | |

+----------(Magnetic Link)--------------------+ |

| |

GND (NC) + |

v

[ DC MOTOR ]

[ M1 ]

^

GND (NC) + |

| |

+----------(Magnetic Link)--------------------+ |

| | |

| (D2 is Reverse Biased) | |

+--> [ K2 Coil || D2 ] --> GND [ K2 Switch (COM) ] --(MOT_B)--+

| [ (Relay 2) ]

[ Node: COIL_B ] ^

^ |

| |

VCC --> [ S2 Button ] VCC (NO)

(Reverse Input) (Right Side Drive)

+-------------------------------------------------------------------------+

| LOGIC KEY: |

| 1. Idle: Both Switches connect COM to NC (GND). Motor is braked (0 V). |

| 2. Press S1: K1 switches to NO (VCC). Current: VCC->MOT_A->MOT_B->GND. |

| 3. Press S2: K2 switches to NO (VCC). Current: VCC->MOT_B->MOT_A->GND. |

+-------------------------------------------------------------------------+

Measurements and tests

To validate the circuit, perform the following steps using a multimeter and visual inspection:

- Idle Check: Ensure neither S1 nor S2 is pressed. Measure voltage between

MOT_AandMOT_B.- Result: Should be 0 V. Both terminals are connected to GND via the NC contacts. The motor is locked (hard to turn by hand due to back EMF shorting).

- Forward Actuation: Press and hold S1.

- Result: K1 clicks. Measure voltage from

MOT_A(Red probe) toMOT_B(Black probe). Voltage should be approximately +5 V. Motor spins Clockwise.

- Result: K1 clicks. Measure voltage from

- Reverse Actuation: Release S1, then press and hold S2.

- Result: K2 clicks. Measure voltage from

MOT_AtoMOT_B. Voltage should be approximately -5 V. Motor spins Counter-Clockwise.

- Result: K2 clicks. Measure voltage from

- Double Press (Safety Test): Press both S1 and S2 simultaneously.

- Result: Both relays click. Voltage between

MOT_AandMOT_Bis 0 V (Both at 5 V potential). Motor does not move.

- Result: Both relays click. Voltage between

SPICE netlist and simulation

Reference SPICE Netlist (ngspice) — excerptFull SPICE netlist (ngspice)

* Practical case: DC Motor Reversing

.width out=256

* Ngspice Netlist

*

* Description: H-Bridge configuration using two SPDT relays to control a DC motor.

* Logic:

* - S1 Pressed -> K1 Active -> MOT_A = 5V, MOT_B = 0V (Forward)

* - S2 Pressed -> K2 Active -> MOT_A = 0V, MOT_B = 5V (Reverse)

* - None Pressed -> MOT_A = 0V, MOT_B = 0V (Stop/Brake)

*

* Simulation Time: 10ms (Captures S1 pulse at 1ms and S2 pulse at 5ms)

.tran 10u 10m

* -----------------------------------------------------------------------------

* Power Supply

* -----------------------------------------------------------------------------

* V1: 5V DC Power Supply, function: Main energy source.

* Connected between VCC (+) and 0 (-).

V1 VCC 0 DC 5

* ... (truncated in public view) ...Copy this content into a .cir file and run with ngspice.

* Practical case: DC Motor Reversing

.width out=256

* Ngspice Netlist

*

* Description: H-Bridge configuration using two SPDT relays to control a DC motor.

* Logic:

* - S1 Pressed -> K1 Active -> MOT_A = 5V, MOT_B = 0V (Forward)

* - S2 Pressed -> K2 Active -> MOT_A = 0V, MOT_B = 5V (Reverse)

* - None Pressed -> MOT_A = 0V, MOT_B = 0V (Stop/Brake)

*

* Simulation Time: 10ms (Captures S1 pulse at 1ms and S2 pulse at 5ms)

.tran 10u 10m

* -----------------------------------------------------------------------------

* Power Supply

* -----------------------------------------------------------------------------

* V1: 5V DC Power Supply, function: Main energy source.

* Connected between VCC (+) and 0 (-).

V1 VCC 0 DC 5

* -----------------------------------------------------------------------------

* User Inputs (Pushbuttons)

* -----------------------------------------------------------------------------

* Modeled as Voltage Controlled Switches (S1, S2) driven by Pulse Sources.

* This strictly simulates the user pressing the button at specific times.

* Stimulus for S1 (Forward Request)

* Pulse: 0V to 5V, starts at 1ms, duration 2ms.

V_USER_S1 CTRL_S1 0 PULSE(0 5 1m 1u 1u 2m 10m)

* Stimulus for S2 (Reverse Request)

* Pulse: 0V to 5V, starts at 5ms, duration 2ms.

V_USER_S2 CTRL_S2 0 PULSE(0 5 5m 1u 1u 2m 10m)

* S1: Momentary Pushbutton (NO)

* Connects VCC to COIL_A when activated by V_USER_S1.

S1 VCC COIL_A CTRL_S1 0 SW_PUSH

* S2: Momentary Pushbutton (NO)

* Connects VCC to COIL_B when activated by V_USER_S2.

S2 VCC COIL_B CTRL_S2 0 SW_PUSH

* -----------------------------------------------------------------------------

* Control Circuit (Relay Coils)

* -----------------------------------------------------------------------------

* Relay K1 Coil Circuit

* K1 Coil: Connects between COIL_A and 0. Modeled as L+R.

L_K1 COIL_A K1_INT 10m

R_K1 K1_INT 0 100

* D1: 1N4007 Diode, function: Flyback protection.

* Cathode to COIL_A, Anode to 0.

D1 0 COIL_A D_1N4007

* Relay K2 Coil Circuit

* K2 Coil: Connects between COIL_B and 0. Modeled as L+R.

L_K2 COIL_B K2_INT 10m

R_K2 K2_INT 0 100

* D2: 1N4007 Diode, function: Flyback protection.

* Cathode to COIL_B, Anode to 0.

D2 0 COIL_B D_1N4007

* -----------------------------------------------------------------------------

* Power Circuit (Motor Drive via Relay Contacts)

* -----------------------------------------------------------------------------

* Relay K1 Contacts (SPDT)

* COM: MOT_A

* NO: VCC (Connected when Coil is Energized/High)

* NC: 0 (Connected when Coil is De-energized/Low)

S_K1_NO VCC MOT_A COIL_A 0 SW_NO_RELAY

S_K1_NC MOT_A 0 COIL_A 0 SW_NC_RELAY

* Relay K2 Contacts (SPDT)

* COM: MOT_B

* NO: VCC (Connected when Coil is Energized/High)

* NC: 0 (Connected when Coil is De-energized/Low)

S_K2_NO VCC MOT_B COIL_B 0 SW_NO_RELAY

S_K2_NC MOT_B 0 COIL_B 0 SW_NC_RELAY

* M1: 5 V DC Motor

* Modeled as a resistive load (50 Ohms) to visualize voltage polarity.

* Connects between MOT_A and MOT_B.

R_M1 MOT_A MOT_B 50

* -----------------------------------------------------------------------------

* Component Models

* -----------------------------------------------------------------------------

* Standard Diode Model

.model D_1N4007 D(IS=1N N=1 RS=0.1 BV=1000 IBV=10u)

* Pushbutton Switch Model (Normally Open)

* Closes (Low R) when Control Voltage > 2.5V

.model SW_PUSH SW(Vt=2.5 Vh=0.1 Ron=0.01 Roff=10Meg)

* Relay Contact Models

* NO (Normally Open): Conducts when Coil > 2.5V

.model SW_NO_RELAY SW(Vt=2.5 Vh=0.1 Ron=0.01 Roff=10Meg)

* NC (Normally Closed): Conducts when Coil < 2.5V

* SPICE SW Logic: If V < Vt, R = Roff. If V > Vt, R = Ron.

* For NC: We want Low R when V < Vt. So Roff=0.01, Ron=10Meg.

.model SW_NC_RELAY SW(Vt=2.5 Vh=0.1 Ron=10Meg Roff=0.01)

* -----------------------------------------------------------------------------

* Output Directives

* -----------------------------------------------------------------------------

* Outputs: Motor Terminals (MOT_A, MOT_B)

* Inputs: Coil Control Voltages (COIL_A, COIL_B)

.print tran V(MOT_A) V(MOT_B) V(COIL_A) V(COIL_B) I(L_K1)

.op

.endSimulation Results (Transient Analysis)

Show raw data table (1104 rows)

Index time v(mot_a) v(mot_b) v(coil_a) v(coil_b) l_k1#branch 0 0.000000e+00 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 1 1.000000e-07 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 2 2.000000e-07 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 3 4.000000e-07 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 4 8.000000e-07 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 5 1.600000e-06 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 6 3.200000e-06 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 7 6.400000e-06 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 8 1.280000e-05 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 9 2.280000e-05 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 10 3.280000e-05 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 11 4.280000e-05 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 12 5.280000e-05 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 13 6.280000e-05 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 14 7.280000e-05 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 15 8.280000e-05 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 16 9.280000e-05 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 17 1.028000e-04 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 18 1.128000e-04 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 19 1.228000e-04 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 20 1.328000e-04 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 21 1.428000e-04 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 22 1.528000e-04 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 23 1.628000e-04 5.000000e-09 5.000000e-09 4.999931e-05 4.999931e-05 4.999931e-07 ... (1080 more rows) ...

Common mistakes and how to avoid them

- Wiring the Motor to NO/NC instead of COM:

- Mistake: Connecting the motor to the Normally Open or Closed pins, and power to the Common pin.

- Solution: Always connect the Load (Motor) to the Common (COM) pin of the SPDT relay for H-bridge configurations. Power and Ground go to NO and NC.

- Omitting Flyback Diodes:

- Mistake: Forgetting D1 and D2 across the relay coils.

- Solution: Always install diodes in reverse bias across coils to prevent high-voltage spikes from damaging switches or power supplies when the relay turns off.

- Using SPST Relays:

- Mistake: Attempting this topology with 4-pin relays that lack a Normally Closed contact.

- Solution: Ensure you use 5-pin SPDT relays so the motor can be grounded when the relay is off.

Troubleshooting

- Motor vibrates but does not spin:

- Cause: Power supply current is insufficient.

- Fix: Check the current rating of your power supply; motors draw high current upon startup.

- Relay clicks but motor does not move:

- Cause: Burnt internal contacts or loose wiring on the COM/NO/NC terminals.

- Fix: Verify continuity between COM and NO when the relay is active using a multimeter.

- Sparks visible inside the relay:

- Cause: Inductive load kickback from the motor.

- Fix: While not always fatal, adding a small capacitor (e.g., 100 nF) across the motor terminals can reduce arcing and noise.

Possible improvements and extensions

- Limit Switches: Add Normally Closed limit switches in series with the relay coils (

COIL_AandCOIL_B) to automatically stop the motor when a mechanism reaches its end of travel. - Speed Control: Insert a high-wattage rheostat or a PWM transistor driver in series with the main

VCCsupply to the relay contacts (not the coils) to vary the motor speed.

More Practical Cases on Prometeo.blog

Find this product and/or books on this topic on Amazon

As an Amazon Associate, I earn from qualifying purchases. If you buy through this link, you help keep this project running.