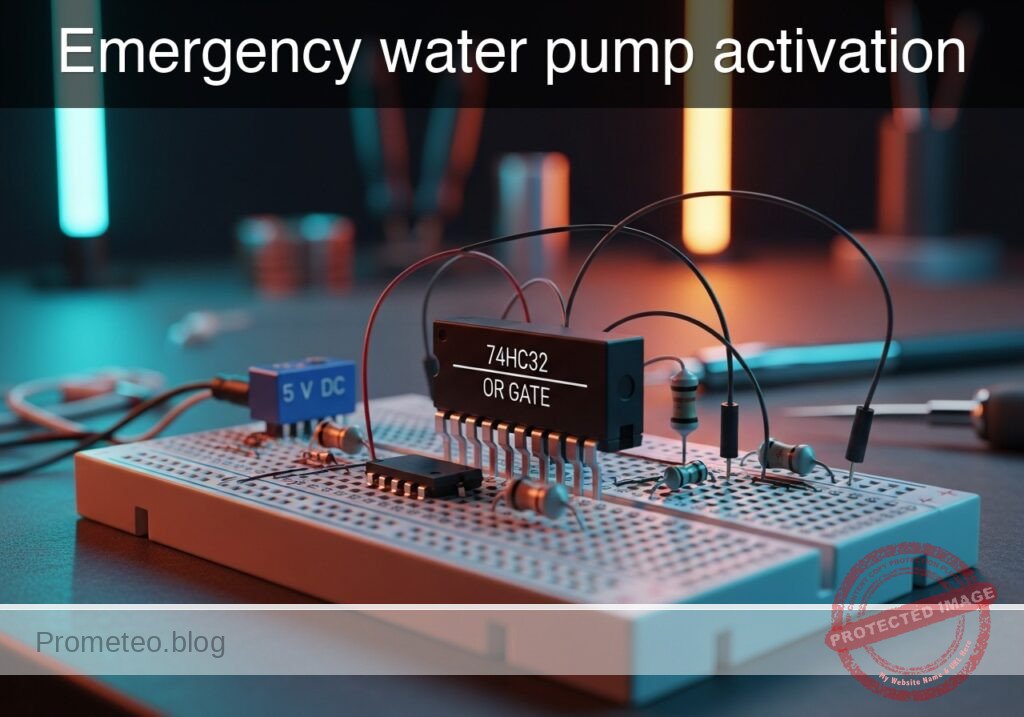

Level: Basic. Design a control system that activates a drainage pump if either of two water level sensors is triggered.

Objective and use case

You will build a logic control circuit using a 74HC32 (OR Gate) to drive a DC motor via a transistor driver whenever water is detected by at least one sensor.

Why it is useful:

* Flood Prevention: Automatically activates a sump pump in a basement when water rises to a critical level.

* Industrial Safety: Prevents tank overflows by draining liquid if primary or secondary high-level sensors are triggered.

* Marine Applications: Activates a boat’s bilge pump if water enters the hull from either the port or starboard side.

* Redundancy: Ensures the pump starts even if one sensor fails (provided the other detects the water).

Expected outcome:

* The motor turns ON if Sensor A is HIGH.

* The motor turns ON if Sensor B is HIGH.

* The motor turns ON if both sensors are HIGH.

* The logic output at the gate pin reads ~5 V (Logic 1) when active.

* Target audience: Basic electronics students and hobbyists.

Materials

- V1: 5 V DC supply, function: Main circuit power.

- S1: SPST Switch, function: Simulates Water Level Sensor A.

- S2: SPST Switch, function: Simulates Water Level Sensor B.

- R1: 10 kΩ resistor, function: Pull-down for Sensor A.

- R2: 10 kΩ resistor, function: Pull-down for Sensor B.

- U1: 74HC32 Quad 2-Input OR Gate.

- R3: 1 kΩ resistor, function: Transistor base current limiting.

- Q1: 2N2222 NPN Transistor, function: Motor driver switch.

- D1: 1N4007 Diode, function: Flyback protection (snubber).

- M1: 5 V DC Motor, function: Drainage pump simulation.

Pin-out of the IC used

Chip: 74HC32 (Quad 2-Input OR Gate)

| Pin | Name | Logic function | Connection in this case |

|---|---|---|---|

| 1 | 1A | Input A | Connected to Node SENS_A |

| 2 | 1B | Input B | Connected to Node SENS_B |

| 3 | 1Y | Output | Connected to Node GATE_OUT |

| 7 | GND | Ground | Connected to Node 0 (GND) |

| 14 | VCC | Power (+5V) | Connected to Node VCC |

Wiring guide

Construct the circuit following these node connections:

- VCC: Connect positive terminal of V1, one side of S1, one side of S2, Pin 14 of U1, and the positive terminal of M1.

- 0 (GND): Connect negative terminal of V1, Pin 7 of U1, Emitter of Q1, bottom of R1, and bottom of R2.

- SENS_A: Connect other side of S1, top of R1, and Pin 1 of U1.

- SENS_B: Connect other side of S2, top of R2, and Pin 2 of U1.

- GATE_OUT: Connect Pin 3 of U1 to one side of R3.

- BASE_NODE: Connect the other side of R3 to the Base of Q1.

- MOTOR_DRIVE: Connect the Collector of Q1, the negative terminal of M1, and the Anode of D1.

- PROTECTION: Connect the Cathode of D1 to VCC (Across the motor).

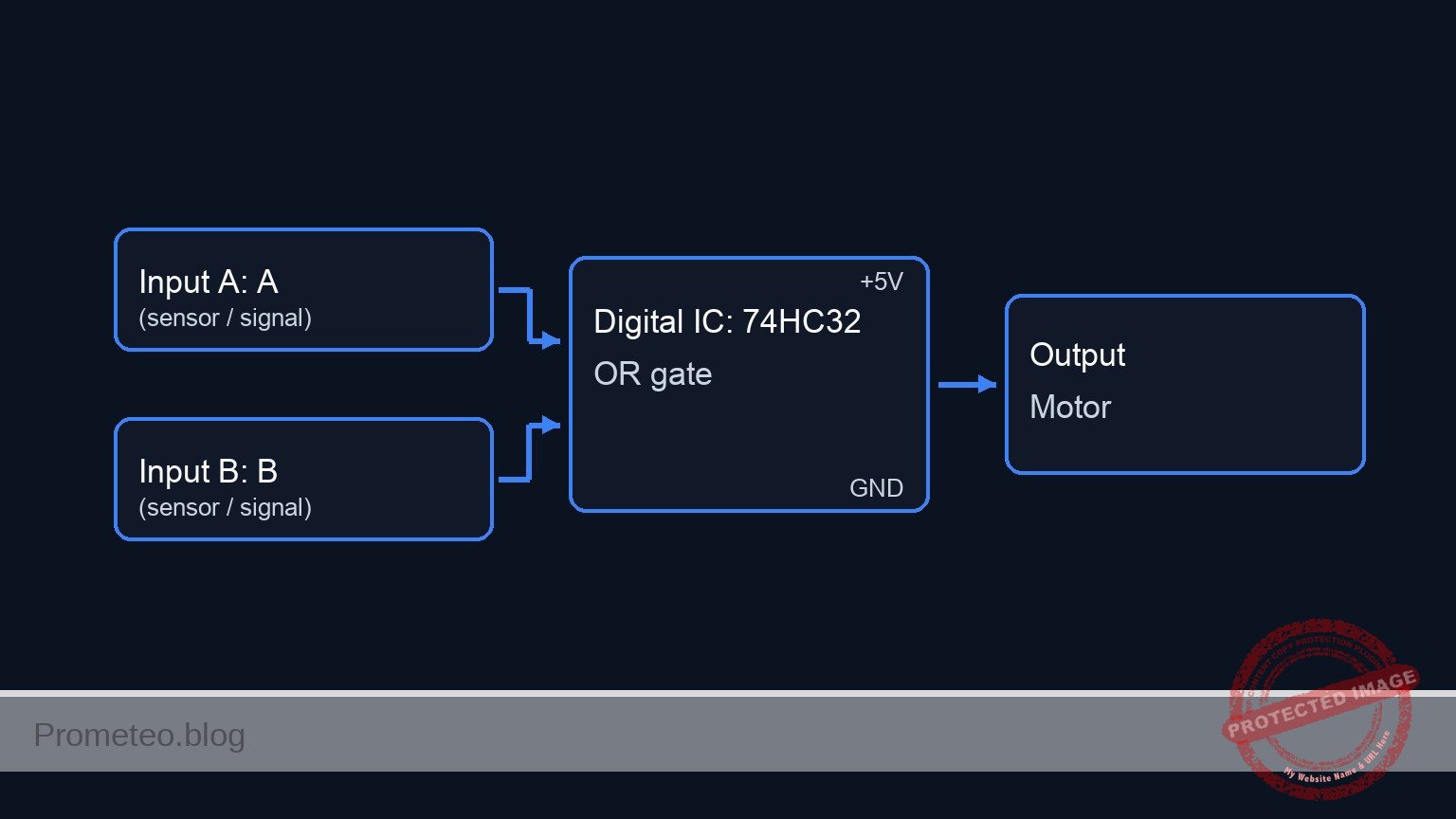

Conceptual block diagram

Schematic

[ INPUTS / SENSORS ] [ LOGIC CONTROL ] [ ACTUATOR / OUTPUT ]

+----------------+

[ Switch S1 ] | |

[ + R1 (PD) ] --(SENS_A / Pin 1)----->| U1: 74HC32 |

| (OR Gate) |

| |--(GATE_OUT / Pin 3)--> [ Resistor R3 ]

| Logic: | |

[ Switch S2 ] | If A OR B | |

[ + R2 (PD) ] --(SENS_B / Pin 2)----->| Then HIGH | |

| | (BASE_NODE)

+----------------+ |

v

[ Q1 NPN Transistor ]

(Electronic Switch)

|

| (Switches GND)

|

(MOTOR_DRIVE)

|

v

[ Motor M1 + Diode D1 ]

(Connected to VCC)

Truth table

This table describes the logic state of the 74HC32 and the resulting physical action of the pump.

| Sensor A (Input 1A) | Sensor B (Input 1B) | Logic Output (Pin 1Y) | Transistor State | Pump Status |

|---|---|---|---|---|

| Low (0) | Low (0) | Low (0) | OFF (Open) | OFF |

| Low (0) | High (1) | High (1) | ON (Saturation) | ON |

| High (1) | Low (0) | High (1) | ON (Saturation) | ON |

| High (1) | High (1) | High (1) | ON (Saturation) | ON |

Measurements and tests

- Power Check: Before connecting the motor, measure the voltage between VCC and GND. It should be stable at 5 V.

- Idle State: Ensure both switches are open. Measure voltage at Pin 3 (GATE_OUT). It should be ~0 V. The motor should be stopped.

- Sensor A Activation: Close S1. Measure voltage at Pin 1 (Input A). It should be 5 V. Pin 3 should go High, and the motor should spin.

- Sensor B Activation: Open S1 and close S2. Verify the motor spins.

- Simultaneous Activation: Close both S1 and S2. The motor should remain spinning.

- Current Draw: Place an ammeter in series with the motor. Note the current consumption (typically 50mA to 200mA for small hobby motors).

SPICE netlist and simulation

Reference SPICE Netlist (ngspice) — excerptFull SPICE netlist (ngspice)

* Emergency water pump activation fixed

* --- Power Supply ---

V1 VCC 0 DC 5

* --- Switches & Sensors ---

* S1: Simulates Water Level Sensor A

V_ACT_A ACT_A 0 PULSE(0 5 0 1u 1u 1m 2m)

S1 VCC SENS_A ACT_A 0 SW_MOD

* R1: Pull-down for Sensor A

R1 SENS_A 0 10k

* S2: Simulates Water Level Sensor B

V_ACT_B ACT_B 0 PULSE(0 5 0 1u 1u 0.5m 1m)

S2 VCC SENS_B ACT_B 0 SW_MOD

* R2: Pull-down for Sensor B

R2 SENS_B 0 10k

* --- Logic Gate U1: 74HC32 (Quad OR) ---

* Pin 1: SENS_A, Pin 2: SENS_B, Pin 3: GATE_OUT, Pin 7: GND, Pin 14: VCC

XU1 SENS_A SENS_B GATE_OUT 0 VCC 74HC32_GATE

* --- Driver Stage ---

* R3: Base resistor

R3 GATE_OUT BASE_NODE 1k

* Q1: NPN Transistor Switch

* Collector: MOTOR_DRIVE, Base: BASE_NODE, Emitter: 0 (GND)

* ... (truncated in public view) ...Copy this content into a .cir file and run with ngspice.

* Emergency water pump activation fixed

* --- Power Supply ---

V1 VCC 0 DC 5

* --- Switches & Sensors ---

* S1: Simulates Water Level Sensor A

V_ACT_A ACT_A 0 PULSE(0 5 0 1u 1u 1m 2m)

S1 VCC SENS_A ACT_A 0 SW_MOD

* R1: Pull-down for Sensor A

R1 SENS_A 0 10k

* S2: Simulates Water Level Sensor B

V_ACT_B ACT_B 0 PULSE(0 5 0 1u 1u 0.5m 1m)

S2 VCC SENS_B ACT_B 0 SW_MOD

* R2: Pull-down for Sensor B

R2 SENS_B 0 10k

* --- Logic Gate U1: 74HC32 (Quad OR) ---

* Pin 1: SENS_A, Pin 2: SENS_B, Pin 3: GATE_OUT, Pin 7: GND, Pin 14: VCC

XU1 SENS_A SENS_B GATE_OUT 0 VCC 74HC32_GATE

* --- Driver Stage ---

* R3: Base resistor

R3 GATE_OUT BASE_NODE 1k

* Q1: NPN Transistor Switch

* Collector: MOTOR_DRIVE, Base: BASE_NODE, Emitter: 0 (GND)

Q1 MOTOR_DRIVE BASE_NODE 0 2N2222MOD

* --- Output Load (Motor) ---

* M1: 5V DC Motor simulation (Inductive Load)

* Fixed: Subcircuit name changed from DC_MOTOR_MODEL to DC_MOTOR to match definition

XM1 VCC MOTOR_DRIVE DC_MOTOR

* --- Protection ---

* D1: Flyback Diode

D1 MOTOR_DRIVE VCC 1N4007MOD

* --- Models and Subcircuits ---

* Switch Model

.model SW_MOD SW(Vt=2.5 Vh=0.1 Ron=0.1 Roff=10Meg)

* Transistor Model (Generic 2N2222)

.model 2N2222MOD NPN(Is=14.34f Xti=3 Eg=1.11 Vaf=74.03 Bf=255.9 Ne=1.307 Ise=14.34f Ikf=.2847 Xtb=1.5 Br=6.092 Nc=2 Isc=0 Ikr=0 Rc=1 Cjc=7.306p Mjc=.3416 Vjc=.75 Fc=.5 Cje=22.01p Mje=.377 Vje=.75 Tr=46.91n Tf=411.1p Itf=.6 Vtf=1.7 Xtf=3 Rb=10)

* Diode Model (Generic 1N4007)

.model 1N4007MOD D(IS=7.027n RS=0.03415 N=1.267 EG=1.11 XTI=3 BV=1000 IBV=10m CJO=10p VJ=0.7 M=0.5 FC=0.5 TT=100n)

* Motor Model (Simple RL series)

.subckt DC_MOTOR POS NEG

Rcoil POS INT 50

Lcoil INT NEG 5m

.ends

* 74HC32 Logic Gate Model (Behavioral)

* Implements OR logic: OUT = 1 if (IN1=1 OR IN2=1)

.subckt 74HC32_GATE IN1 IN2 OUT GND VCC

B_OR OUT GND V=V(VCC) * ( (1/(1+exp(-20*(V(IN1)-2.5)))) + (1/(1+exp(-20*(V(IN2)-2.5)))) - ( (1/(1+exp(-20*(V(IN1)-2.5)))) * (1/(1+exp(-20*(V(IN2)-2.5)))) ) )

.ends

* --- Simulation Directives ---

.tran 10u 2.5m

* Print required nodes for validation

.print tran V(SENS_A) V(SENS_B) V(GATE_OUT) V(BASE_NODE) V(MOTOR_DRIVE)

.endSimulation Results (Transient Analysis)

Show raw data table (2750 rows)

Index time v(sens_a) v(sens_b) v(gate_out) 0 0.000000e+00 4.995005e-03 4.995005e-03 2.131385e-21 1 1.000000e-08 4.995005e-03 4.995005e-03 2.131385e-21 2 2.000000e-08 4.995005e-03 4.995005e-03 2.131385e-21 3 4.000000e-08 4.995005e-03 4.995005e-03 2.131385e-21 4 8.000000e-08 4.995005e-03 4.995005e-03 2.131385e-21 5 1.600000e-07 4.995005e-03 4.995005e-03 2.131385e-21 6 3.200000e-07 4.995005e-03 4.995005e-03 2.131385e-21 7 3.600000e-07 4.995005e-03 4.995005e-03 2.131385e-21 8 4.300000e-07 4.995005e-03 4.995005e-03 2.131385e-21 9 4.493750e-07 4.995005e-03 4.995005e-03 2.131385e-21 10 4.832812e-07 4.995005e-03 4.995005e-03 2.131385e-21 11 5.162979e-07 4.999950e+00 4.999950e+00 5.000000e+00 12 5.395702e-07 4.999950e+00 4.999950e+00 5.000000e+00 13 5.611432e-07 4.999950e+00 4.999950e+00 5.000000e+00 14 5.884211e-07 4.999950e+00 4.999950e+00 5.000000e+00 15 6.429769e-07 4.999950e+00 4.999950e+00 5.000000e+00 16 7.520886e-07 4.999950e+00 4.999950e+00 5.000000e+00 17 9.703119e-07 4.999950e+00 4.999950e+00 5.000000e+00 18 1.000000e-06 4.999950e+00 4.999950e+00 5.000000e+00 19 1.030157e-06 4.999950e+00 4.999950e+00 5.000000e+00 20 1.090472e-06 4.999950e+00 4.999950e+00 5.000000e+00 21 1.211102e-06 4.999950e+00 4.999950e+00 5.000000e+00 22 1.452361e-06 4.999950e+00 4.999950e+00 5.000000e+00 23 1.934879e-06 4.999950e+00 4.999950e+00 5.000000e+00 ... (2726 more rows) ...

Common mistakes and how to avoid them

- Floating Inputs: Forgetting the pull-down resistors (R1, R2).

- Solution: Always connect inputs to ground via a resistor (10kΩ) so they default to 0 V when switches are open.

- Missing Flyback Diode: Omitting D1 across the motor.

- Solution: Inductive loads generate voltage spikes when turned off. Always place a diode in reverse bias across the motor to protect the transistor.

- Overloading the Gate: Connecting the motor directly to the 74HC32 output pin.

- Solution: Logic gates can only supply small currents (~20mA). Use a transistor (Q1) to handle the higher current required by the motor.

Troubleshooting

- Symptom: Motor runs continuously even when switches are open.

- Cause: Inputs are floating or the transistor is shorted.

- Fix: Check R1/R2 connections or replace Q1.

- Symptom: IC gets very hot immediately.

- Cause: VCC and GND pins are reversed or shorted.

- Fix: Disconnect power immediately and verify Pin 14 and Pin 7 wiring.

- Symptom: Logic output is High (5V), but motor does not spin.

- Cause: Base resistor (R3) too high or transistor gain too low.

- Fix: Verify R3 is 1kΩ. Ensure the motor power supply is adequate.

Possible improvements and extensions

- Visual Indicators: Add an LED with a current-limiting resistor in parallel with the motor to provide a visual warning when the pump is active.

- Hysteresis/Latching: Replace the OR gate with an SR Latch logic. This would keep the pump running even if the water level drops momentarily, ensuring a full drain cycle until a bottom sensor resets it.

More Practical Cases on Prometeo.blog

Find this product and/or books on this topic on Amazon

As an Amazon Associate, I earn from qualifying purchases. If you buy through this link, you help keep this project running.