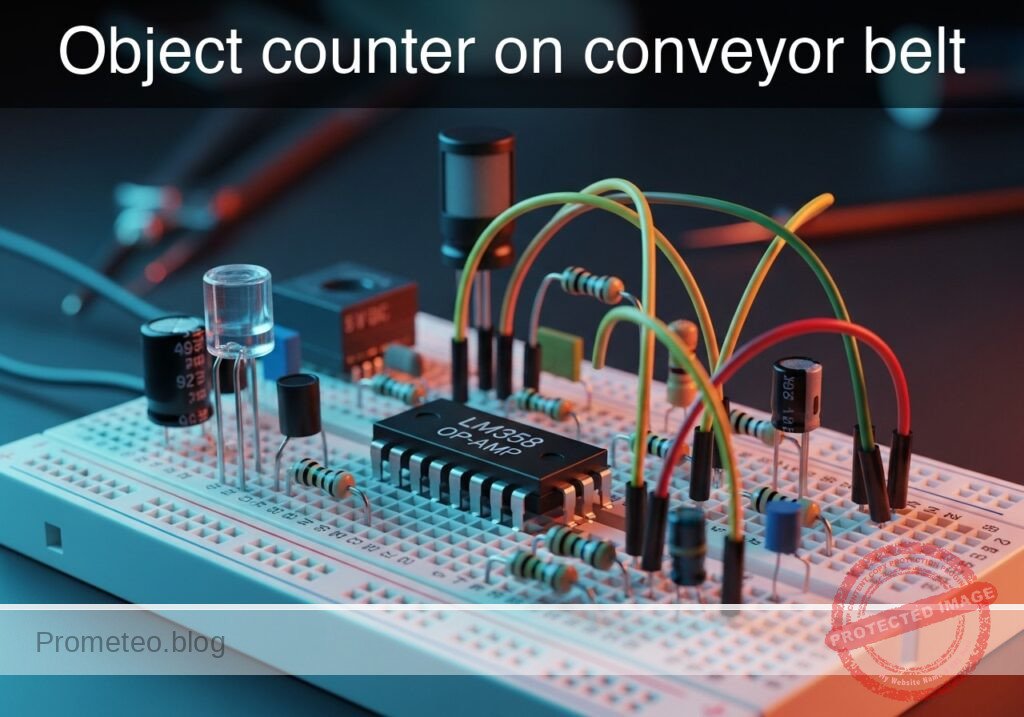

Level: Basic – Build a light interruption sensor system to detect objects moving on a line.

Objective and use case

In this practical case, you will build an optical barrier using a photoresistor (LDR) and an operational amplifier configured as a voltage comparator. The circuit detects when an opaque object interrupts a continuous beam of light, triggering a signal that can be counted or processed.

Why it is useful:

* Industrial automation: Used to count products moving on a conveyor belt.

* Safety barriers: Detects if a person or object crosses a dangerous boundary.

* Intruder alarms: Triggers a warning when a beam of invisible or visible light is broken.

* Parking systems: Detects the presence of a vehicle in a specific spot.

Expected outcome:

* State A (Light path clear): The sensor receives light, and the output indicator (Red LED) remains OFF (Logic Low).

* State B (Object detected): The object blocks the light, increasing LDR resistance. The output indicator turns ON (Logic High).

* Signal Threshold: The comparator switches states when the sensor voltage crosses the adjustable reference voltage (approx. 2.5 V).

Target audience: Level Basic

Materials

- V1: 5 V DC power supply, function: main circuit power.

- R1: 10 kΩ resistor, function: voltage divider top for reference.

- R2: 10 kΩ resistor, function: voltage divider bottom for reference.

- R3: 10 kΩ resistor, function: pull-up resistor for the sensor node.

- R4: Photoresistor (LDR), function: light detection sensor.

- R5: 330 Ω resistor, function: current limiting for output indicator LED.

- R6: 330 Ω resistor, function: current limiting for emitter LED.

- D1: White LED, function: light emitter (simulates the beam source).

- D2: Red LED, function: output indicator (object detected).

- U1: LM358 or similar OpAmp, function: voltage comparator.

Wiring guide

This circuit relies on comparing two voltages: a fixed reference (V_REF) and a variable sensor voltage (V_SENSE).

Power Connections

* V1 (+) connects to node VCC.

* V1 (-) connects to node 0 (GND).

* U1 (Pin 8 / VCC) connects to VCC.

* U1 (Pin 4 / GND) connects to 0.

Reference Voltage (V_REF)

* R1 connects between VCC and V_REF.

* R2 connects between V_REF and 0.

* U1 (Pin 2 / Inverting Input) connects to V_REF.

* Note: This sets a fixed threshold of 2.5 V.

Sensor Voltage (V_SENSE)

* R3 connects between VCC and V_SENSE.

* R4 (LDR) connects between V_SENSE and 0.

* U1 (Pin 3 / Non-Inverting Input) connects to V_SENSE.

* Logic: When light is blocked, R4 resistance increases, V_SENSE rises. If V_SENSE > V_REF, Output goes High.

Light Emitter (Source)

* R6 connects between VCC and NODE_EMIT.

* D1 (Anode) connects to NODE_EMIT.

* D1 (Cathode) connects to 0.

* Place D1 physically facing R4 (LDR).

Output Stage

* U1 (Pin 1 / Output) connects to V_OUT.

* R5 connects between V_OUT and NODE_LED.

* D2 (Anode) connects to NODE_LED.

* D2 (Cathode) connects to 0.

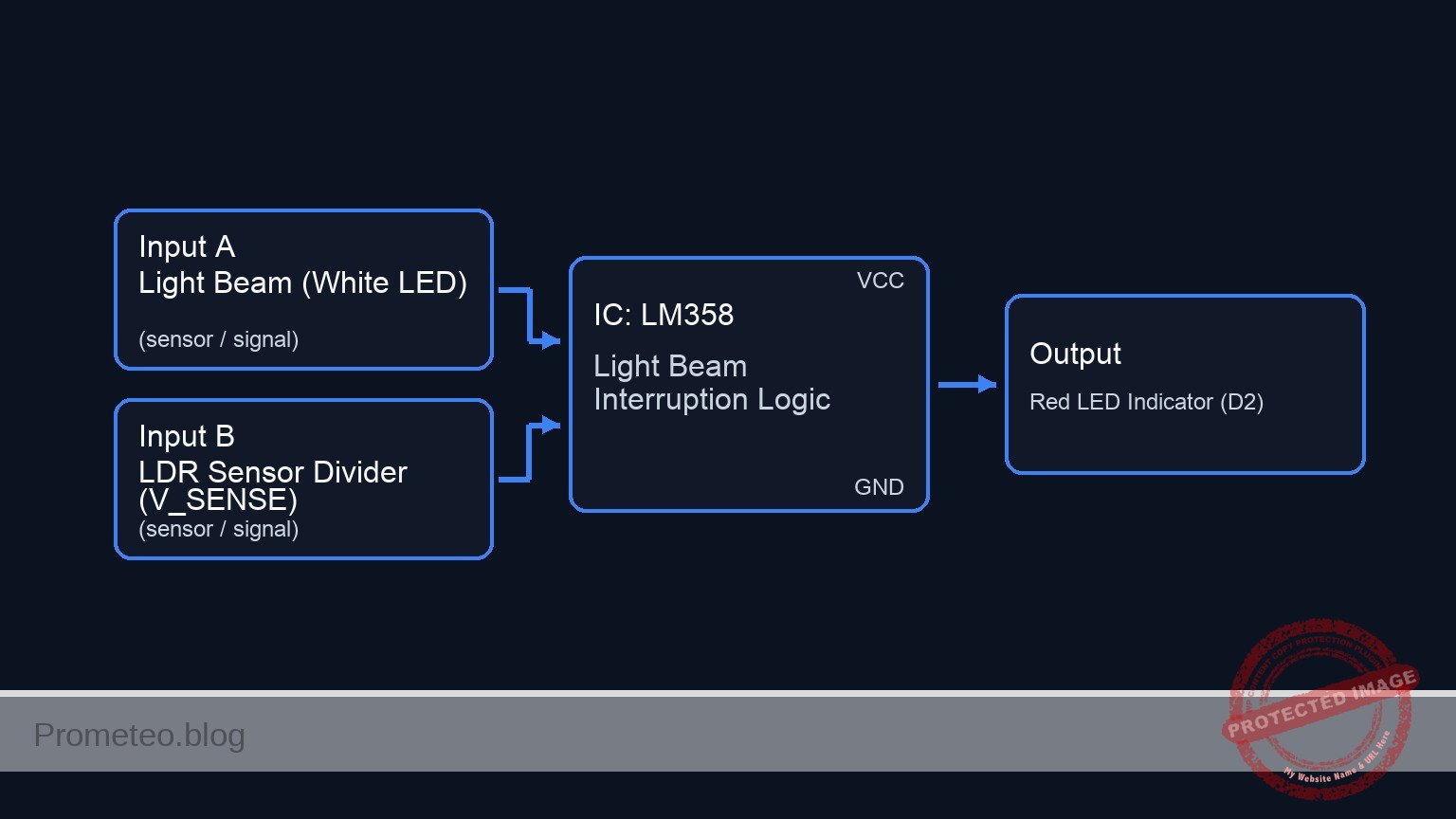

Conceptual block diagram

Schematic

[ INPUTS / SENSORS ] [ LOGIC / PROCESSING ] [ OUTPUTS ]

[ LIGHT SOURCE ]

[ VCC -> R6 -> D1 (White) ]

|

(Light Beam Path)

|

V

[ SENSOR DIVIDER ]

[ VCC -> R3 -> Node -> R4 ] --(V_SENSE)-->+----------------+

[ (R4=LDR, varies w/ light)] | Pin 3 (+) |

| |

| U1 LM358 |

| (Comparator) | --(Pin 1)--> [ R5 (330) ] --> [ D2 (Red LED) ] --> GND

| |

[ REFERENCE DIVIDER ] | |

[ VCC -> R1 -> Node -> R2 ] --(V_REF)---->| Pin 2 (-) |

[ (Fixed 2.5 V Threshold) ] +----------------+

Measurements and tests

- Reference Check: Use a multimeter to measure the voltage between

V_REFand0. It should be approximately 2.5 V (half of VCC). - Light Condition (Clear Path): Ensure the Emitter LED (D1) shines on the LDR (R4). Measure

V_SENSE. It should be lower thanV_REF(e.g., < 2.0 V). The Output LED (D2) should be OFF. - Dark Condition (Object Detected): Place an object (cardboard or finger) between D1 and R4. Measure

V_SENSE. It should rise higher thanV_REF(e.g., > 3.0 V). The Output LED (D2) should turn ON. - Comparator Output: Measure

V_OUTrelative to0. In the «Dark» state, it should be close to 3.5 V – 4 V (High). In the «Light» state, it should be close to 0 V (Low).

SPICE netlist and simulation

Reference SPICE Netlist (ngspice) — excerptFull SPICE netlist (ngspice)

* Practical case: Object counter on conveyor belt

* -----------------------------------------------------------------------------

* Power Supply

* Wiring: V1 (+) to VCC, V1 (-) to 0 (GND)

* -----------------------------------------------------------------------------

V1 VCC 0 DC 5

* -----------------------------------------------------------------------------

* Reference Voltage Divider

* Wiring: R1 between VCC and V_REF, R2 between V_REF and 0

* Function: Sets threshold voltage (approx 2.5V)

* -----------------------------------------------------------------------------

R1 VCC V_REF 10k

R2 V_REF 0 10k

* -----------------------------------------------------------------------------

* Sensor Network

* Wiring: R3 between VCC and V_SENSE, R4 (LDR) between V_SENSE and 0

* Simulation Note: R4 is modeled as a behavioral resistor to simulate the

* ... (truncated in public view) ...Copy this content into a .cir file and run with ngspice.

* Practical case: Object counter on conveyor belt

* -----------------------------------------------------------------------------

* Power Supply

* Wiring: V1 (+) to VCC, V1 (-) to 0 (GND)

* -----------------------------------------------------------------------------

V1 VCC 0 DC 5

* -----------------------------------------------------------------------------

* Reference Voltage Divider

* Wiring: R1 between VCC and V_REF, R2 between V_REF and 0

* Function: Sets threshold voltage (approx 2.5V)

* -----------------------------------------------------------------------------

R1 VCC V_REF 10k

R2 V_REF 0 10k

* -----------------------------------------------------------------------------

* Sensor Network

* Wiring: R3 between VCC and V_SENSE, R4 (LDR) between V_SENSE and 0

* Simulation Note: R4 is modeled as a behavioral resistor to simulate the

* changing resistance of an LDR when an object blocks the light.

* -----------------------------------------------------------------------------

R3 VCC V_SENSE 10k

* R4 (LDR) Implementation:

* Resistance = 1k (Light/No Object) to 100k (Dark/Object Detected)

* Controlled by dummy voltage source V_OBJ_CTRL

R4 V_SENSE 0 R='1k + 99k / (1 + exp(-50 * (V(V_OBJ_CTRL) - 2.5)))'

* -----------------------------------------------------------------------------

* Light Emitter (Source)

* Wiring: R6 between VCC and NODE_EMIT, D1 Anode to NODE_EMIT, Cathode to 0

* -----------------------------------------------------------------------------

R6 VCC NODE_EMIT 330

D1 NODE_EMIT 0 D_WHITE

* -----------------------------------------------------------------------------

* Comparator (U1: LM358)

* Wiring: Pin 8=VCC, Pin 4=0, Pin 3=V_SENSE (+), Pin 2=V_REF (-), Pin 1=V_OUT

* -----------------------------------------------------------------------------

XU1 V_SENSE V_REF VCC 0 V_OUT LM358_COMP

* -----------------------------------------------------------------------------

* Output Stage

* Wiring: R5 between V_OUT and NODE_LED, D2 Anode to NODE_LED, Cathode to 0

* -----------------------------------------------------------------------------

R5 V_OUT NODE_LED 330

D2 NODE_LED 0 D_RED

* -----------------------------------------------------------------------------

* Dynamic Stimuli (Object Simulation)

* This source drives the behavioral LDR (R4).

* Logic: 0V = Clear (Light), 5V = Object (Dark)

* Timing: Wait 50us, Pulse High for 100us, Repeat every 300us

* -----------------------------------------------------------------------------

V_OBJ V_OBJ_CTRL 0 PULSE(0 5 50u 10u 10u 100u 300u)

* -----------------------------------------------------------------------------

* Models and Subcircuits

* -----------------------------------------------------------------------------

.model D_WHITE D(IS=1e-14 N=4 RS=10) ; High Vf simulation for White LED

.model D_RED D(IS=1e-12 N=2 RS=5) ; Standard Red LED

* Behavioral OpAmp Subcircuit (Comparator)

* Pinout Order: Non-Inv(+), Inv(-), VCC, GND, Output

.subckt LM358_COMP P M V_POS V_NEG OUT

* Sigmoid function for robust switching behavior (Rail-to-Rail logic approx)

* V(OUT) approaches V_POS when P > M, V_NEG when P < M

B1 OUT 0 V = V(V_POS) * (1 / (1 + exp(-100 * (V(P) - V(M)))))

.ends

* -----------------------------------------------------------------------------

* Analysis Directives

* -----------------------------------------------------------------------------

.op

.tran 1u 500u

* Print required signals for batch processing

.print tran V(V_SENSE) V(V_REF) V(V_OUT) V(V_OBJ_CTRL)Simulation Results (Transient Analysis)

Show raw data table (1064 rows)

Index time v(v_sense) v(v_ref) v(v_out) 0 0.000000e+00 4.545455e-01 2.500000e+00 7.345271e-89 1 1.000000e-08 4.545455e-01 2.500000e+00 7.345271e-89 2 2.000000e-08 4.545455e-01 2.500000e+00 7.345271e-89 3 4.000000e-08 4.545455e-01 2.500000e+00 7.345271e-89 4 8.000000e-08 4.545455e-01 2.500000e+00 7.345271e-89 5 1.600000e-07 4.545455e-01 2.500000e+00 7.345271e-89 6 3.200000e-07 4.545455e-01 2.500000e+00 7.345271e-89 7 6.400000e-07 4.545455e-01 2.500000e+00 7.345271e-89 8 1.280000e-06 4.545455e-01 2.500000e+00 7.345271e-89 9 2.280000e-06 4.545455e-01 2.500000e+00 7.345271e-89 10 3.280000e-06 4.545455e-01 2.500000e+00 7.345271e-89 11 4.280000e-06 4.545455e-01 2.500000e+00 7.345271e-89 12 5.280000e-06 4.545455e-01 2.500000e+00 7.345271e-89 13 6.280000e-06 4.545455e-01 2.500000e+00 7.345271e-89 14 7.280000e-06 4.545455e-01 2.500000e+00 7.345271e-89 15 8.280000e-06 4.545455e-01 2.500000e+00 7.345271e-89 16 9.280000e-06 4.545455e-01 2.500000e+00 7.345271e-89 17 1.028000e-05 4.545455e-01 2.500000e+00 7.345271e-89 18 1.128000e-05 4.545455e-01 2.500000e+00 7.345271e-89 19 1.228000e-05 4.545455e-01 2.500000e+00 7.345271e-89 20 1.328000e-05 4.545455e-01 2.500000e+00 7.345271e-89 21 1.428000e-05 4.545455e-01 2.500000e+00 7.345271e-89 22 1.528000e-05 4.545455e-01 2.500000e+00 7.345271e-89 23 1.628000e-05 4.545455e-01 2.500000e+00 7.345271e-89 ... (1040 more rows) ...

Common mistakes and how to avoid them

- Swapping OpAmp inputs: Connecting the Reference to the Non-Inverting (+) input instead of the Inverting (-) input will reverse the logic (LED turns OFF when object is detected). Ensure

V_SENSEgoes to the Non-Inverting (+) pin for «Dark Detection». - Ambient Light interference: The LDR is very sensitive. If the room is bright, the «Dark» state might not be dark enough to trigger the threshold. Use a small tube or tape to shield the LDR.

- Incorrect LDR placement: If the LDR (R4) is placed in the top leg of the voltage divider (swapped with R3), the logic is inverted. Ensure R4 connects to Ground (

0).

Troubleshooting

- Output LED never turns ON:

- Check if the object actually blocks the light completely.

- Measure

V_SENSE. If it never exceeds 2.5 V, increase the value of R3 (e.g., to 22 kΩ) to raise the voltage sensitivity.

- Output LED never turns OFF:

- The LDR might be receiving insufficient light from the Emitter.

- Check alignment of D1 and R4.

- Measure

V_REF. If R1 is disconnected,V_REFmight be 0 V, causing the output to stay High.

- Output flickers:

- The light source might be unstable, or the voltage is hovering exactly at the threshold. Add a decoupling capacitor (e.g., 100 nF) across the power rails near the OpAmp.

Possible improvements and extensions

- Adjustable Sensitivity: Replace R1 or R2 with a 10 kΩ potentiometer. This allows you to fine-tune the

V_REFthreshold to work in different ambient light conditions. - Hysteresis (Schmidt Trigger): Add a high-value feedback resistor (e.g., 1 MΩ) between the Output (

V_OUT) and the Non-Inverting input (V_SENSE). This prevents the LED from flickering if the object moves slowly across the beam.

More Practical Cases on Prometeo.blog

Find this product and/or books on this topic on Amazon

As an Amazon Associate, I earn from qualifying purchases. If you buy through this link, you help keep this project running.