Level: Medium. Design a control circuit to start industrial machinery from a main panel or a remote safety remote.

Objective and use case

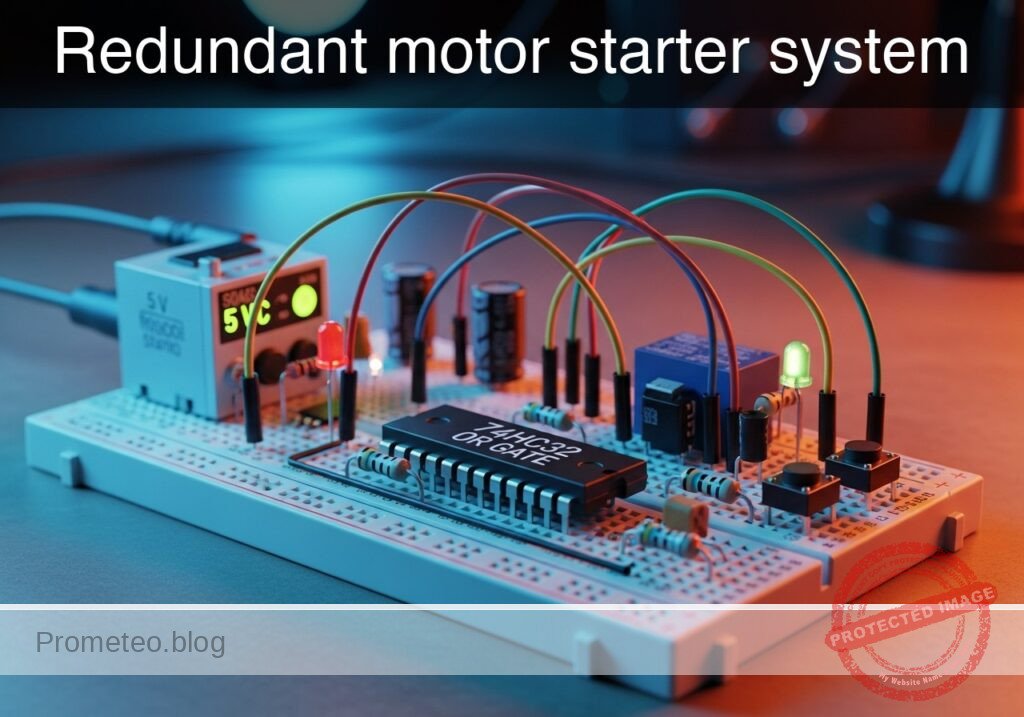

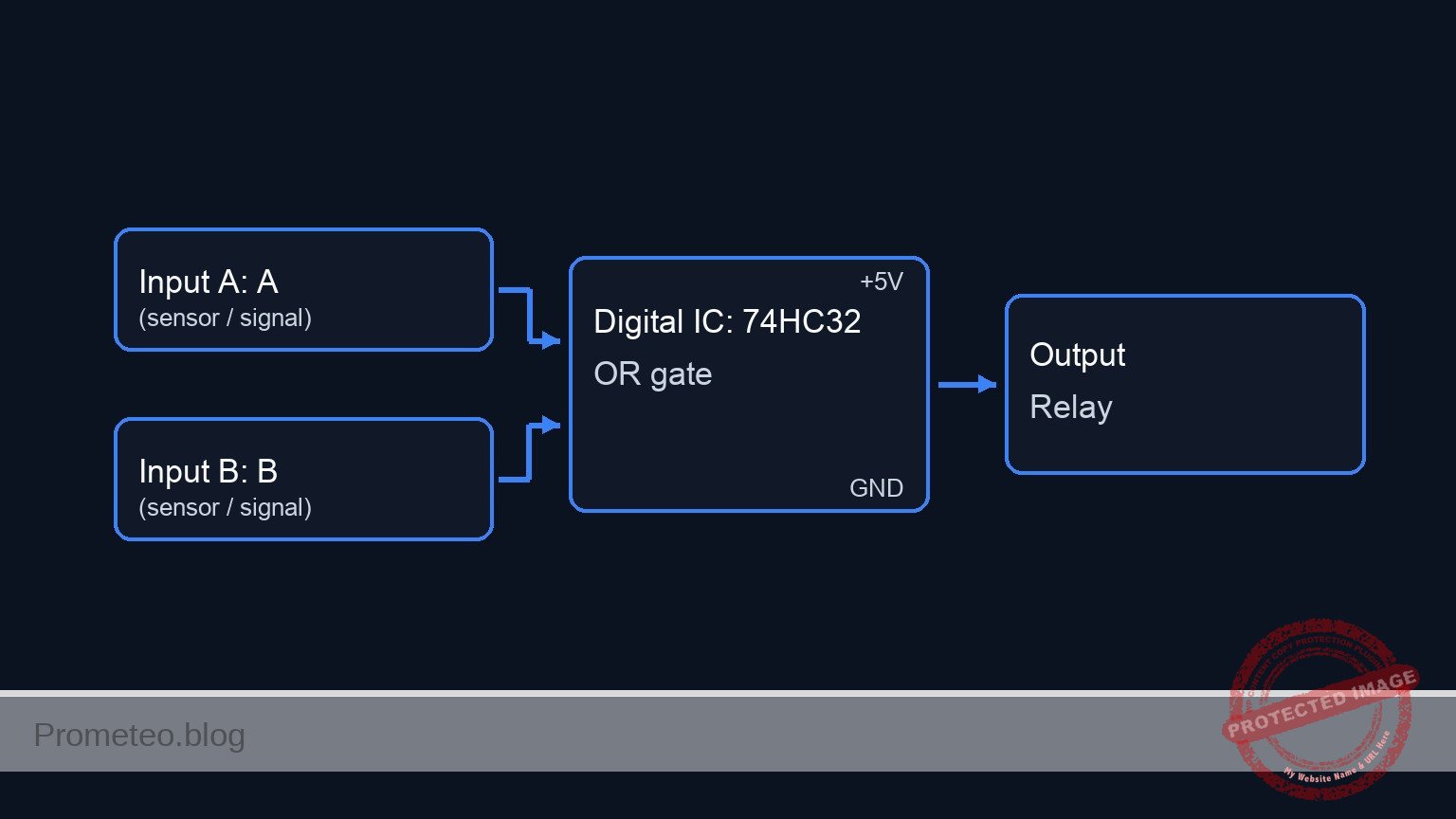

In this practical case, you will build a digital control circuit using an OR logic gate to operate a heavy-duty DC motor via a relay. The system allows the motor to be started from two distinct physical locations: the main control panel or a remote safety station.

- Operational Redundancy: Ensures machinery can be activated from a secondary location if the primary panel is inaccessible.

- Convenience: Allows operators to start a conveyor belt or fan from either end of a production line.

- Signal Isolation: Uses low-voltage logic (5V) to safely switch a high-power inductive load (motor) via a relay driver.

Expected outcome:

* Pressing Button A (Main) starts the motor immediately.

* Pressing Button B (Remote) starts the motor immediately.

* Logic Output High ($V_{OH}$) measures approximately 5V when either button is pressed.

* The relay produces an audible «click» and the DC motor spins when the logic condition is met.

Target audience: Electronics students and hobbyists familiar with basic logic gates and relay driving.

Materials

- V1: 5 V DC power supply, function: Main logic and relay power

- U1: 74HC32, function: Quad 2-input OR gate

- S1: Pushbutton (normally open), function: Main Start Panel

- S2: Pushbutton (normally open), function: Remote Start Command

- R1: 10 kΩ resistor, function: Pull-down for Input A

- R2: 10 kΩ resistor, function: Pull-down for Input B

- R3: 1 kΩ resistor, function: Transistor base current limiting

- Q1: 2N2222 NPN Transistor, function: Relay driver switch

- D1: 1N4007 Diode, function: Flyback protection for relay coil

- K1: 5 V Relay (SPDT), function: High-current switching

- M1: 5 V DC Motor, function: Industrial load simulation

Pin-out of the IC used

Chip: 74HC32 (Quad 2-Input OR Gate)

| Pin | Name | Logic function | Connection in this case |

|---|---|---|---|

| 1 | 1A | Input A | Connected to Node START_MAIN |

| 2 | 1B | Input B | Connected to Node START_REMOTE |

| 3 | 1Y | Output | Connected to Node LOGIC_OUT |

| 7 | GND | Ground | Connected to Node 0 |

| 14 | VCC | Power Supply | Connected to Node VCC |

Wiring guide

- V1 connects between node

VCCand node0(GND). - S1 connects between node

VCCand nodeSTART_MAIN. - R1 connects between node

START_MAINand node0. - S2 connects between node

VCCand nodeSTART_REMOTE. - R2 connects between node

START_REMOTEand node0. - U1 Pin 1 (1A) connects to node

START_MAIN. - U1 Pin 2 (1B) connects to node

START_REMOTE. - U1 Pin 3 (1Y) connects to node

LOGIC_OUT. - U1 Pin 14 (VCC) connects to node

VCC. - U1 Pin 7 (GND) connects to node

0. - R3 connects between node

LOGIC_OUTand nodeBASE_DRIVE. - Q1 Base connects to node

BASE_DRIVE. - Q1 Emitter connects to node

0. - Q1 Collector connects to node

RELAY_COIL_LO. - K1 Coil Positive connects between node

VCCand nodeRELAY_COIL_LO(Note: Coil connects VCC to Collector). - D1 connects between node

RELAY_COIL_LO(Anode) and nodeVCC(Cathode) (Reverse biased). - K1 Common contact connects to node

VCC. - K1 Normally Open (NO) contact connects to node

MOTOR_PWR. - M1 connects between node

MOTOR_PWRand node0.

Conceptual block diagram

Schematic

Practical case: Redundant motor starter system

[ INPUTS ] [ LOGIC ] [ DRIVER ] [ OUTPUT / LOAD ]

[ S1: Main Start ] --+

|

[ R1: Pull-down ] --+--(Pin 1)-->+------------+

| |

| U1: 74HC32 | (Base Sig)

| (OR Gate) |--(Pin 3)--> [ R3: 1k ] --> [ Q1: NPN ] --(Sink)--> [ K1: Relay Coil ]

| | | (w/ D1 Diode)

[ S2: Remote Cmd ] --+--(Pin 2)-->+------------+ [ GND ] |

| (Magnetic)

[ R2: Pull-down ] --+ |

v

[ K1: NO Contact ]

|

(Switched 5V)

|

v

[ M1: DC Motor ]

|

[ GND ]

Truth table

This system uses positive logic (active HIGH).

| Input A (Main) | Input B (Remote) | Output Y (Logic) | Relay State | Motor State |

|---|---|---|---|---|

| 0 (Open) | 0 (Open) | 0 (Low) | OFF | Stopped |

| 0 (Open) | 1 (Pressed) | 1 (High) | ON | Running |

| 1 (Pressed) | 0 (Open) | 1 (High) | ON | Running |

| 1 (Pressed) | 1 (Pressed) | 1 (High) | ON | Running |

Measurements and tests

- Input Validation ($V_{in_high}$): With neither button pressed, measure the voltage at

START_MAINandSTART_REMOTE. It should be 0V. Press S1 and verify the voltage rises to approx 5V. - Logic Output Verification ($V_{out_logic}$): Place a multimeter probe on Pin 3 of U1. Press S1 OR S2. The voltage should jump from near 0V to $\approx$ 5V.

- Actuator Test (Motor RPM): Observe the motor. It should spin when the logic output is High. If using a tachometer, verify the

Motor_RPMis consistent regardless of which button (S1 or S2) triggered the start.

SPICE netlist and simulation

Reference SPICE Netlist (ngspice) — excerptFull SPICE netlist (ngspice)

* Redundant motor starter system

* Created based on BOM and Wiring Guide

* --- Power Supply ---

* V1: 5 V DC power supply

V1 VCC 0 DC 5

* --- Input Section ---

* S1: Pushbutton (Main Start)

* Wiring: Connects VCC to START_MAIN.

* Implementation: Voltage Controlled Switch driven by a Stimulus Pulse (V_ACT1)

* Timing: Period 200us, covers logic states 00, 10, 11, 01 combined with S2

V_ACT1 ACT1 0 PULSE(0 5 10u 1u 1u 100u 200u)

S1 VCC START_MAIN ACT1 0 SW_PUSH

* R1: 10 kΩ resistor (Pull-down for Input A)

R1 START_MAIN 0 10k

* S2: Pushbutton (Remote Start)

* Wiring: Connects VCC to START_REMOTE.

* Implementation: Voltage Controlled Switch driven by a Stimulus Pulse (V_ACT2)

V_ACT2 ACT2 0 PULSE(0 5 10u 1u 1u 200u 400u)

S2 VCC START_REMOTE ACT2 0 SW_PUSH

* R2: 10 kΩ resistor (Pull-down for Input B)

R2 START_REMOTE 0 10k

* Model for Pushbuttons

.model SW_PUSH SW(Vt=2.5 Ron=0.1 Roff=10Meg)

* ... (truncated in public view) ...Copy this content into a .cir file and run with ngspice.

* Redundant motor starter system

* Created based on BOM and Wiring Guide

* --- Power Supply ---

* V1: 5 V DC power supply

V1 VCC 0 DC 5

* --- Input Section ---

* S1: Pushbutton (Main Start)

* Wiring: Connects VCC to START_MAIN.

* Implementation: Voltage Controlled Switch driven by a Stimulus Pulse (V_ACT1)

* Timing: Period 200us, covers logic states 00, 10, 11, 01 combined with S2

V_ACT1 ACT1 0 PULSE(0 5 10u 1u 1u 100u 200u)

S1 VCC START_MAIN ACT1 0 SW_PUSH

* R1: 10 kΩ resistor (Pull-down for Input A)

R1 START_MAIN 0 10k

* S2: Pushbutton (Remote Start)

* Wiring: Connects VCC to START_REMOTE.

* Implementation: Voltage Controlled Switch driven by a Stimulus Pulse (V_ACT2)

V_ACT2 ACT2 0 PULSE(0 5 10u 1u 1u 200u 400u)

S2 VCC START_REMOTE ACT2 0 SW_PUSH

* R2: 10 kΩ resistor (Pull-down for Input B)

R2 START_REMOTE 0 10k

* Model for Pushbuttons

.model SW_PUSH SW(Vt=2.5 Ron=0.1 Roff=10Meg)

* --- Logic Section ---

* U1: 74HC32 Quad 2-input OR gate

* Pins: 1(A), 2(B), 3(Y), 7(GND), 14(VCC)

* Implemented as a subcircuit to expose all pins

XU1 START_MAIN START_REMOTE LOGIC_OUT VCC 0 74HC32_OR

.subckt 74HC32_OR A B Y VCC GND

* Behavioral OR logic using continuous tanh function for convergence

* Logic: If (A + B) > Threshold(2.5V), Output High

* Function scales 0-1 range to 0-5V

B1 Y GND V = 5 * (tanh(10 * (V(A) + V(B) - 2.5)) + 1) / 2

.ends

* --- Driver Section ---

* R3: 1 kΩ resistor (Base current limiting)

R3 LOGIC_OUT BASE_DRIVE 1k

* Q1: 2N2222 NPN Transistor (Relay driver)

* Connections: Base=BASE_DRIVE, Collector=RELAY_COIL_LO, Emitter=0

Q1 RELAY_COIL_LO BASE_DRIVE 0 2N2222

.model 2N2222 NPN(IS=1E-14 VAF=100 BF=200 IKF=0.3 XTB=1.5 BR=3 CJC=8p CJE=25p TR=46n TF=411p ITF=0.6 VTF=1.7 XTF=3 RB=10 RC=0.3 RE=0.2)

* --- Relay Section ---

* K1: 5 V Relay (SPDT)

* Coil Connection: VCC to RELAY_COIL_LO

* Modeled as Inductor + Series Resistance

L_K1 VCC K1_INT 10m

R_K1_COIL K1_INT RELAY_COIL_LO 100

* D1: 1N4007 Diode (Flyback protection)

* Connections: Anode=RELAY_COIL_LO, Cathode=VCC

D1 RELAY_COIL_LO VCC 1N4007

.model 1N4007 D(IS=7n RS=0.034 N=1.26 BV=1000 IBV=5u CJO=10p)

* Relay Contact Switch

* Wiring: Common(VCC) to NO(MOTOR_PWR)

* Controlled by voltage across the coil (VCC - RELAY_COIL_LO)

* Threshold set to 3V (Energized state)

S_K1 VCC MOTOR_PWR VCC RELAY_COIL_LO SW_RELAY

.model SW_RELAY SW(Vt=3.0 Ron=0.05 Roff=100Meg)

* --- Motor Load ---

* M1: 5 V DC Motor

* Wiring: MOTOR_PWR to 0

* Modeled as resistive load with slight inductance

R_M1 MOTOR_PWR M1_INT 20

L_M1 M1_INT 0 1m

* --- Simulation Directives ---

.op

.tran 1u 500u

* Print directive for transient analysis

.print tran V(START_MAIN) V(START_REMOTE) V(LOGIC_OUT) V(BASE_DRIVE) V(RELAY_COIL_LO) V(MOTOR_PWR)

.endSimulation Results (Transient Analysis)

Show raw data table (1304 rows)

Index time v(start_main) v(start_remote) v(logic_out) 0 0.000000e+00 4.995005e-03 4.995005e-03 0.000000e+00 1 1.000000e-08 4.995005e-03 4.995005e-03 0.000000e+00 2 2.000000e-08 4.995005e-03 4.995005e-03 0.000000e+00 3 4.000000e-08 4.995005e-03 4.995005e-03 0.000000e+00 4 8.000000e-08 4.995005e-03 4.995005e-03 0.000000e+00 5 1.600000e-07 4.995005e-03 4.995005e-03 0.000000e+00 6 3.200000e-07 4.995005e-03 4.995005e-03 0.000000e+00 7 6.400000e-07 4.995005e-03 4.995005e-03 0.000000e+00 8 1.280000e-06 4.995005e-03 4.995005e-03 0.000000e+00 9 2.280000e-06 4.995005e-03 4.995005e-03 0.000000e+00 10 3.280000e-06 4.995005e-03 4.995005e-03 0.000000e+00 11 4.280000e-06 4.995005e-03 4.995005e-03 0.000000e+00 12 5.280000e-06 4.995005e-03 4.995005e-03 0.000000e+00 13 6.280000e-06 4.995005e-03 4.995005e-03 0.000000e+00 14 7.280000e-06 4.995005e-03 4.995005e-03 0.000000e+00 15 8.280000e-06 4.995005e-03 4.995005e-03 0.000000e+00 16 9.280000e-06 4.995005e-03 4.995005e-03 0.000000e+00 17 1.000000e-05 4.995005e-03 4.995005e-03 0.000000e+00 18 1.010000e-05 4.995005e-03 4.995005e-03 0.000000e+00 19 1.026000e-05 4.995005e-03 4.995005e-03 0.000000e+00 20 1.030750e-05 4.995005e-03 4.995005e-03 0.000000e+00 21 1.039062e-05 4.995005e-03 4.995005e-03 0.000000e+00 22 1.041363e-05 4.995005e-03 4.995005e-03 0.000000e+00 23 1.045390e-05 4.995005e-03 4.995005e-03 0.000000e+00 ... (1280 more rows) ...

Common mistakes and how to avoid them

- Floating Inputs: Forgetting R1 or R2 allows the input pins to «float,» causing the motor to switch on randomly due to electrostatic noise. Always use pull-down resistors with the 74HC series.

- Missing Flyback Diode: Omitting D1 allows high-voltage spikes from the relay coil to destroy Q1 or reset U1 when the motor turns off. Always install the diode in reverse parallel to the coil.

- Driving Relay Directly: Trying to power the relay coil directly from U1 Pin 3 will damage the IC, as logic gates cannot supply enough current. Always use a transistor (Q1) as a driver.

Troubleshooting

- Symptom: The motor runs continuously and never stops.

- Cause: One input is floating or shorted to VCC.

- Fix: Check R1/R2 connections and ensure buttons are not «Normally Closed» type.

- Symptom: Logic Output goes High, but Relay does not click.

- Cause: Transistor Q1 is not conducting or R3 is too high.

- Fix: Check Q1 pinout (C-B-E) and ensure the emitter goes to Ground.

- Symptom: The system resets or glitches when the relay turns off.

- Cause: Inductive kickback noise.

- Fix: Verify D1 is installed correctly (Cathode to VCC) and add a 100nF decoupling capacitor near U1 VCC.

Possible improvements and extensions

- Latch Circuit: Add a feedback loop so the motor stays on after the button is released (Start/Stop station).

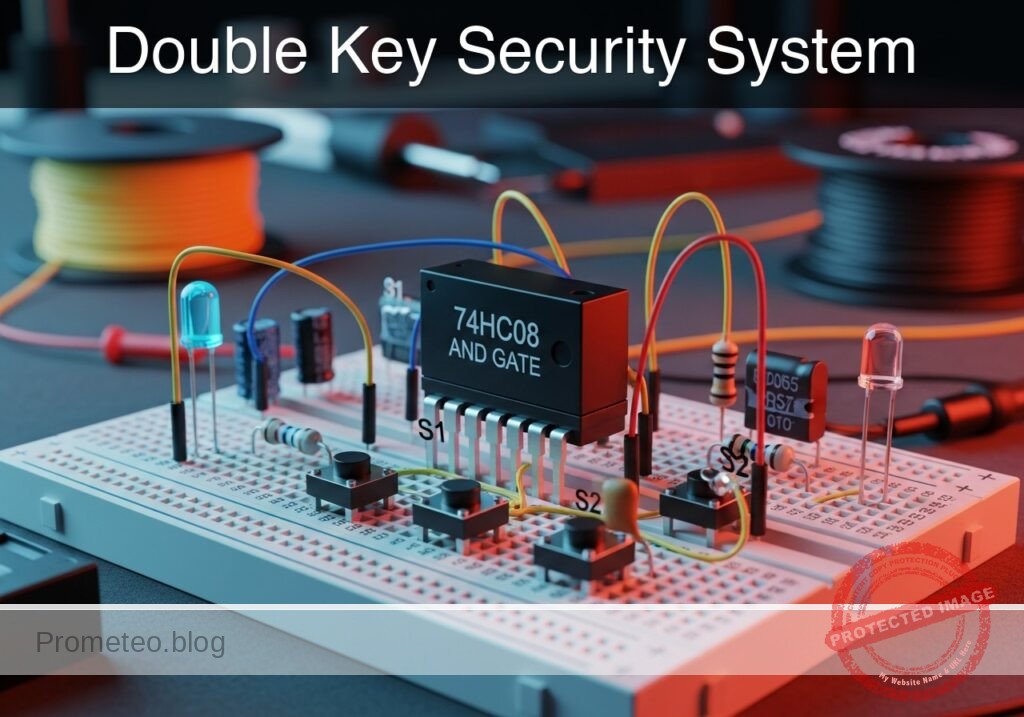

- Safety Interlock: Add a 74HC08 (AND gate) in series with a «Safety Switch» so the motor only runs if the safety guard is closed AND a button is pressed.

More Practical Cases on Prometeo.blog

Find this product and/or books on this topic on Amazon

As an Amazon Associate, I earn from qualifying purchases. If you buy through this link, you help keep this project running.