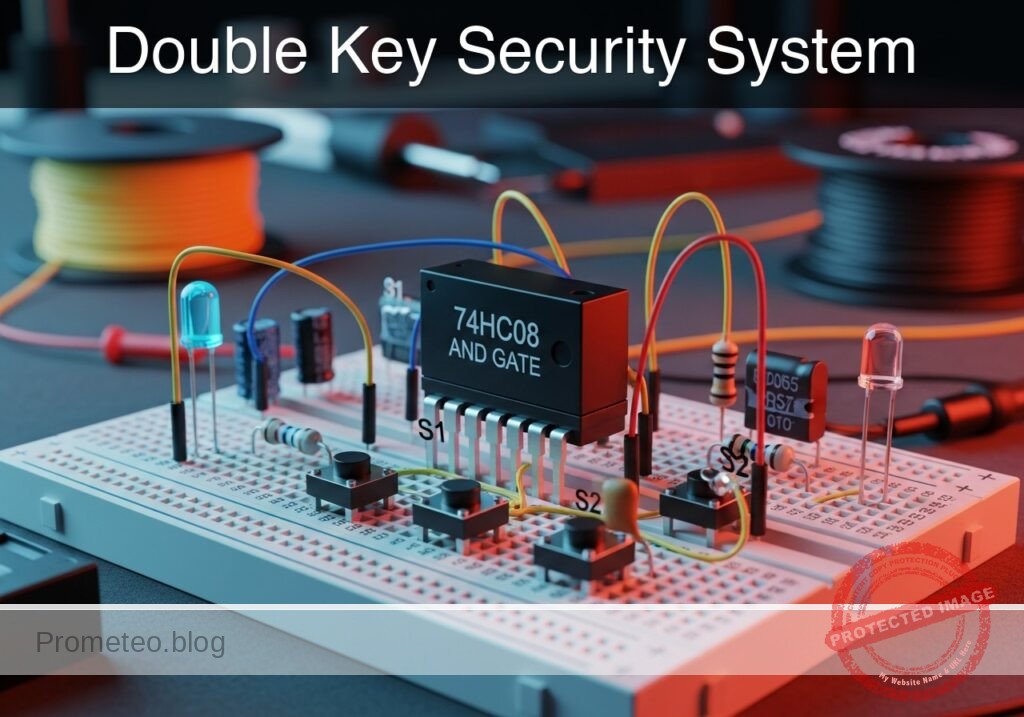

Level: Basic — Implement a safety logic circuit requiring two simultaneous inputs to activate a load.

Objective and use case

In this practical case, you will build a digital logic circuit that enforces a «two-hand control» safety mechanism. The load (simulated by an LED) will only activate when two separate pushbuttons are pressed simultaneously, preventing accidental operation.

Why it is useful:

* Industrial Safety: Prevents operators from injuring their hands in hydraulic presses or cutting machines by forcing them to use both hands to start the cycle.

* Dual Authorization: Similar logic is used in security systems where two keys or signals are required to authorize an action (e.g., bank vaults).

* Interlock Systems: Ensures multiple conditions (e.g., Door Closed AND Start Button Pressed) are met before a machine runs.

Expected outcome:

* Rest State: The output LED remains OFF when no buttons or only one button is pressed.

* Active State: The output LED turns ON strictly when both buttons are held down.

* Logic Level: The output voltage at the gate pin reads High ($\approx$ 5 V) only during simultaneous activation.

* Visual Feedback: Immediate response from the LED indicating the «Safe to Operate» condition.

Target audience: Students and hobbyists learning basic digital logic and safety interlocks.

Materials

- U1: 74HC08, function: Quad 2-input AND gate IC.

- V1: 5 V DC supply, function: Main power source.

- SW1: Normally Open (NO) Pushbutton, function: Left-hand safety trigger.

- SW2: Normally Open (NO) Pushbutton, function: Right-hand safety trigger.

- R1: 10 kΩ resistor, function: Pull-down resistor for Input A.

- R2: 10 kΩ resistor, function: Pull-down resistor for Input B.

- R3: 330 Ω resistor, function: Current limiting for output LED.

- D1: Green LED, function: Indicator for «Motor Active» (Load).

Pin-out of the 74HC08

The 74HC08 contains four independent AND gates. We will use the first gate.

| Pin | Name | Logic function | Connection in this case |

|---|---|---|---|

| 1 | 1A | Input A | Connected to Node A (SW1) |

| 2 | 1B | Input B | Connected to Node B (SW2) |

| 3 | 1Y | Output | Connected to Node Y (to LED driver) |

| 7 | GND | Ground | Connected to Node 0 |

| 14 | VCC | Supply Voltage | Connected to Node VCC (+5V) |

Wiring guide

Construct the circuit using the following node connections. Ensure the power supply is off while wiring.

-

Power Nodes:

- Connect V1 positive terminal to Node VCC.

- Connect V1 negative terminal to Node 0 (GND).

- Connect U1 Pin 14 to VCC.

- Connect U1 Pin 7 to 0.

-

Input A Logic (Left Hand):

- Connect one side of SW1 to VCC.

- Connect the other side of SW1 to Node A.

- Connect R1 between Node A and Node 0 (Pull-down).

- Connect U1 Pin 1 to Node A.

-

Input B Logic (Right Hand):

- Connect one side of SW2 to VCC.

- Connect the other side of SW2 to Node B.

- Connect R2 between Node B and Node 0 (Pull-down).

- Connect U1 Pin 2 to Node B.

-

Output Logic (Load):

- Connect U1 Pin 3 to Node Y.

- Connect R3 between Node Y and Node LED_ANODE.

- Connect D1 Anode to Node LED_ANODE.

- Connect D1 Cathode to Node 0.

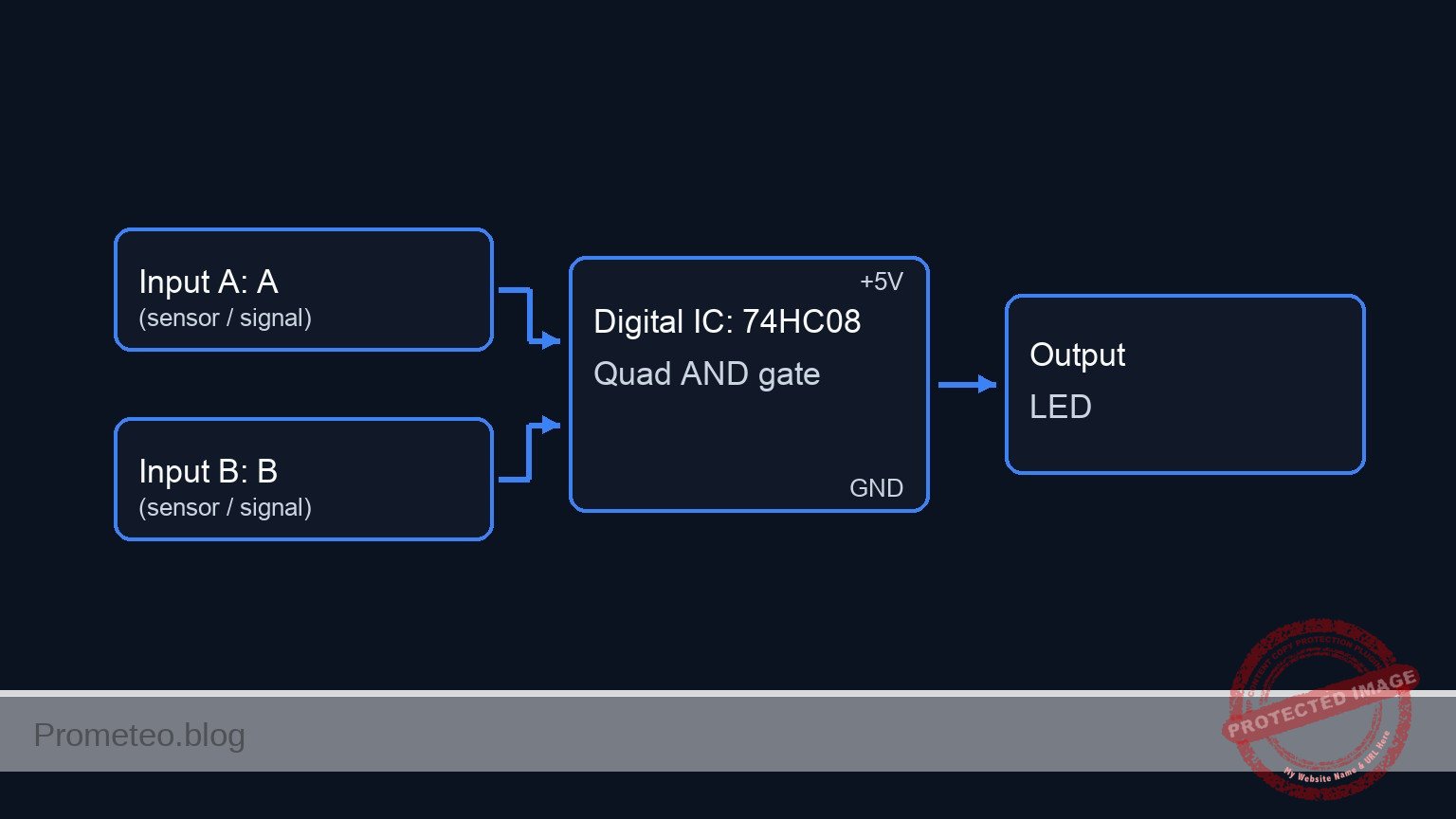

Conceptual block diagram

Schematic

Practical case: Safe Hydraulic Press Control

[ INPUTS / SENSORS ] [ LOGIC PROCESSING ] [ OUTPUT / ACTUATOR ]

+------------------+

(VCC) --> [ SW1: Left Hand ] --(Node A)---> | Pin 1 |

(NO Push) | | |

v | U1: 74HC08 |

[ R1: 10k ] | (AND Gate) |

(Pull-Down) | | --(Node Y)--> [ R3: 330 ] --> [ D1: Green LED ] --> (GND)

| | Pin 3 | (Limit) (Motor Active)

(GND) | |

| |

(VCC) --> [ SW2: Right Hand ]--(Node B)---> | Pin 2 |

(NO Push) | +------------------+

v

[ R2: 10k ]

(Pull-Down)

|

(GND)

Note: U1 Power Connections (Pin 14 to VCC, Pin 7 to GND) are implied for IC operation.

Truth table

This circuit implements the Boolean function $Y = A \cdot B$.

| SW1 (Input A) | SW2 (Input B) | Output Y (Logic) | LED Status | System State |

|---|---|---|---|---|

| Open (0) | Open (0) | Low (0) | OFF | Safe / Stop |

| Open (0) | Closed (1) | Low (0) | OFF | Safe / Stop |

| Closed (1) | Open (0) | Low (0) | OFF | Safe / Stop |

| Closed (1) | Closed (1) | High (1) | ON | Active / Run |

Measurements and tests

- Preparation: Set your multimeter to DC Voltage mode. Power on the V1 source (5 V).

- Idle Check: With no buttons pressed, measure the voltage at Node Y. It should be $\approx$ 0 V. The LED is OFF.

- Single Button Test: Press and hold SW1 only. Measure voltage at Node A ($\approx$ 5 V) and Node Y ($\approx$ 0 V). The LED remains OFF.

- Single Button Test: Press and hold SW2 only. Measure voltage at Node B ($\approx$ 5 V) and Node Y ($\approx$ 0 V). The LED remains OFF.

- Simultaneous Activation: Press both SW1 and SW2. Measure voltage at Node Y. It should read $\approx$ 3.5 V to 4.5 V (depending on the specific HC/LS logic family load and VCC). The LED turns ON.

SPICE netlist and simulation

Reference SPICE Netlist (ngspice) — excerptFull SPICE netlist (ngspice)

* Practical case: Safe Hydraulic Press Control

.title Safe Hydraulic Press Control

*******************************************************************************

* Component Models

*******************************************************************************

* Pushbutton Switch Model (Ideal Voltage Controlled Switch)

* Simulates the mechanical contact closing when control voltage is high (> 2.5V)

.model SW_PUSH SW(Vt=2.5 Vh=0.1 Ron=0.01 Roff=10Meg)

* LED Model (Green)

* Standard Green LED parameters

.model LED_GREEN D(IS=1e-22 RS=10 N=2 BV=5 IBV=10u CJO=10p TT=10n)

* 74HC08 Quad 2-input AND Gate (Behavioral Model for Simulation)

* Implements one gate of the IC.

* Pins: 1=InputA, 2=InputB, 3=OutputY, 7=GND, 14=VCC

.subckt 74HC08_GATE 1 2 3 7 14

* Behavioral Voltage Source using continuous Sigmoid function for convergence

* Y = VCC * (Sigmoid(A) * Sigmoid(B))

* Threshold centered at 2.5V with steep slope (k=50)

B1 3 7 V = V(14) * (1 / (1 + exp(-50 * (V(1) - 2.5)))) * (1 / (1 + exp(-50 * (V(2) - 2.5))))

.ends

*******************************************************************************

* Main Power Supply

*******************************************************************************

* V1: 5V DC supply connected to Node VCC and Node 0 (GND)

* ... (truncated in public view) ...Copy this content into a .cir file and run with ngspice.

* Practical case: Safe Hydraulic Press Control

.title Safe Hydraulic Press Control

*******************************************************************************

* Component Models

*******************************************************************************

* Pushbutton Switch Model (Ideal Voltage Controlled Switch)

* Simulates the mechanical contact closing when control voltage is high (> 2.5V)

.model SW_PUSH SW(Vt=2.5 Vh=0.1 Ron=0.01 Roff=10Meg)

* LED Model (Green)

* Standard Green LED parameters

.model LED_GREEN D(IS=1e-22 RS=10 N=2 BV=5 IBV=10u CJO=10p TT=10n)

* 74HC08 Quad 2-input AND Gate (Behavioral Model for Simulation)

* Implements one gate of the IC.

* Pins: 1=InputA, 2=InputB, 3=OutputY, 7=GND, 14=VCC

.subckt 74HC08_GATE 1 2 3 7 14

* Behavioral Voltage Source using continuous Sigmoid function for convergence

* Y = VCC * (Sigmoid(A) * Sigmoid(B))

* Threshold centered at 2.5V with steep slope (k=50)

B1 3 7 V = V(14) * (1 / (1 + exp(-50 * (V(1) - 2.5)))) * (1 / (1 + exp(-50 * (V(2) - 2.5))))

.ends

*******************************************************************************

* Main Power Supply

*******************************************************************************

* V1: 5V DC supply connected to Node VCC and Node 0 (GND)

V1 VCC 0 DC 5

*******************************************************************************

* Input A Logic (Left Hand)

*******************************************************************************

* V_ACT_LEFT: Virtual actuator (Finger) for Left Button

* Generates a pulse: ON for 50us, OFF for 50us (Period 100us)

V_ACT_LEFT CTRL_LEFT 0 PULSE(0 5 0 1u 1u 50u 100u)

* SW1: Left Safety Trigger

* Connects VCC to Node_A when CTRL_LEFT is High

S1 VCC Node_A CTRL_LEFT 0 SW_PUSH

* R1: 10k Pull-down resistor for Input A

R1 Node_A 0 10k

*******************************************************************************

* Input B Logic (Right Hand)

*******************************************************************************

* V_ACT_RIGHT: Virtual actuator (Finger) for Right Button

* Generates a pulse: ON for 100us, OFF for 100us (Period 200us)

* Timing creates overlap with Left button to test AND logic (1+1, 0+1, 1+0, 0+0)

V_ACT_RIGHT CTRL_RIGHT 0 PULSE(0 5 0 1u 1u 100u 200u)

* SW2: Right Safety Trigger

* Connects VCC to Node_B when CTRL_RIGHT is High

S2 VCC Node_B CTRL_RIGHT 0 SW_PUSH

* R2: 10k Pull-down resistor for Input B

R2 Node_B 0 10k

*******************************************************************************

* Logic Processing (U1: 74HC08)

*******************************************************************************

* U1: AND Gate processing Left (A) and Right (B) inputs

* Connections: Pin1=Node_A, Pin2=Node_B, Pin3=Node_Y, Pin7=0(GND), Pin14=VCC

XU1 Node_A Node_B Node_Y 0 VCC 74HC08_GATE

*******************************************************************************

* Output Logic (Load)

*******************************************************************************

* R3: Current limiting resistor (330 Ohm)

R3 Node_Y Node_LED_ANODE 330

* D1: Green LED Indicator (Motor Active)

* Anode to R3, Cathode to GND

D1 Node_LED_ANODE 0 LED_GREEN

*******************************************************************************

* Simulation Commands

*******************************************************************************

* Transient analysis for 250us to cover full truth table sequence

.tran 1u 250u

* Print directives for logging signal states

.print tran V(Node_A) V(Node_B) V(Node_Y) V(Node_LED_ANODE)

.endSimulation Results (Transient Analysis)

Show raw data table (786 rows)

Index time v(node_a) v(node_b) v(node_y) 0 0.000000e+00 4.995005e-03 4.995005e-03 2.199277e-108 1 1.000000e-08 4.995005e-03 4.995005e-03 2.199277e-108 2 2.000000e-08 4.995005e-03 4.995005e-03 2.199277e-108 3 4.000000e-08 4.995005e-03 4.995005e-03 2.199277e-108 4 8.000000e-08 4.995005e-03 4.995005e-03 2.199277e-108 5 1.600000e-07 4.995005e-03 4.995005e-03 2.199277e-108 6 3.200000e-07 4.995005e-03 4.995005e-03 2.199277e-108 7 3.600000e-07 4.995005e-03 4.995005e-03 2.199277e-108 8 4.300000e-07 4.995005e-03 4.995005e-03 2.199277e-108 9 4.493750e-07 4.995005e-03 4.995005e-03 2.199277e-108 10 4.832812e-07 4.995005e-03 4.995005e-03 2.199277e-108 11 5.162979e-07 4.999995e+00 4.999995e+00 5.000000e+00 12 5.474468e-07 4.999995e+00 4.999995e+00 5.000000e+00 13 5.779894e-07 4.999995e+00 4.999995e+00 5.000000e+00 14 6.039341e-07 4.999995e+00 4.999995e+00 5.000000e+00 15 6.320124e-07 4.999995e+00 4.999995e+00 5.000000e+00 16 6.881690e-07 4.999995e+00 4.999995e+00 5.000000e+00 17 8.004820e-07 4.999995e+00 4.999995e+00 5.000000e+00 18 1.000000e-06 4.999995e+00 4.999995e+00 5.000000e+00 19 1.022463e-06 4.999995e+00 4.999995e+00 5.000000e+00 20 1.067388e-06 4.999995e+00 4.999995e+00 5.000000e+00 21 1.157238e-06 4.999995e+00 4.999995e+00 5.000000e+00 22 1.336939e-06 4.999995e+00 4.999995e+00 5.000000e+00 23 1.696341e-06 4.999995e+00 4.999995e+00 5.000000e+00 ... (762 more rows) ...

Common mistakes and how to avoid them

- Floating Inputs: Forgetting R1 or R2 causes the inputs to «float» when buttons are open, leading to erratic LED flickering or false triggering. Solution: Ensure pull-down resistors connect the inputs to ground.

- Confusing 7408 with 7400: The 7408 is an AND gate; the 7400 is a NAND gate. If the LED is ON when buttons are not pressed, you likely used the wrong chip. Solution: Check the markings on the IC package.

- LED Polarity: The LED does not light up even when Logic Y is High. Solution: Ensure the longer leg (Anode) faces the resistor/IC and the shorter leg (Cathode) faces Ground.

Troubleshooting

- Symptom: LED is always ON, regardless of buttons.

- Cause: Input pins shorted to VCC or incorrect IC (e.g., OR gate 74HC32 used by mistake).

- Fix: Check wiring at Pins 1 and 2; verify IC part number.

- Symptom: LED is very dim when both buttons are pressed.

- Cause: R3 value is too high or VCC is too low.

- Fix: Ensure R3 is around 220 Ω to 330 Ω; check V1 is 5 V.

- Symptom: Circuit works for one button but ignores the other.

- Cause: Broken switch or disconnected jumper wire on one input.

- Fix: Use a multimeter to verify continuity across SW1 and SW2 when pressed.

Possible improvements and extensions

- Power Interface: Replace the LED with an NPN transistor (like 2N2222) and a relay to control a real high-voltage motor.

- Master Enable Switch: Add a third switch connected to a third input (using a 3-input AND gate like 74HC11) to act as a «Key Switch» that must be active before the two hand buttons work.

More Practical Cases on Prometeo.blog

Find this product and/or books on this topic on Amazon

As an Amazon Associate, I earn from qualifying purchases. If you buy through this link, you help keep this project running.