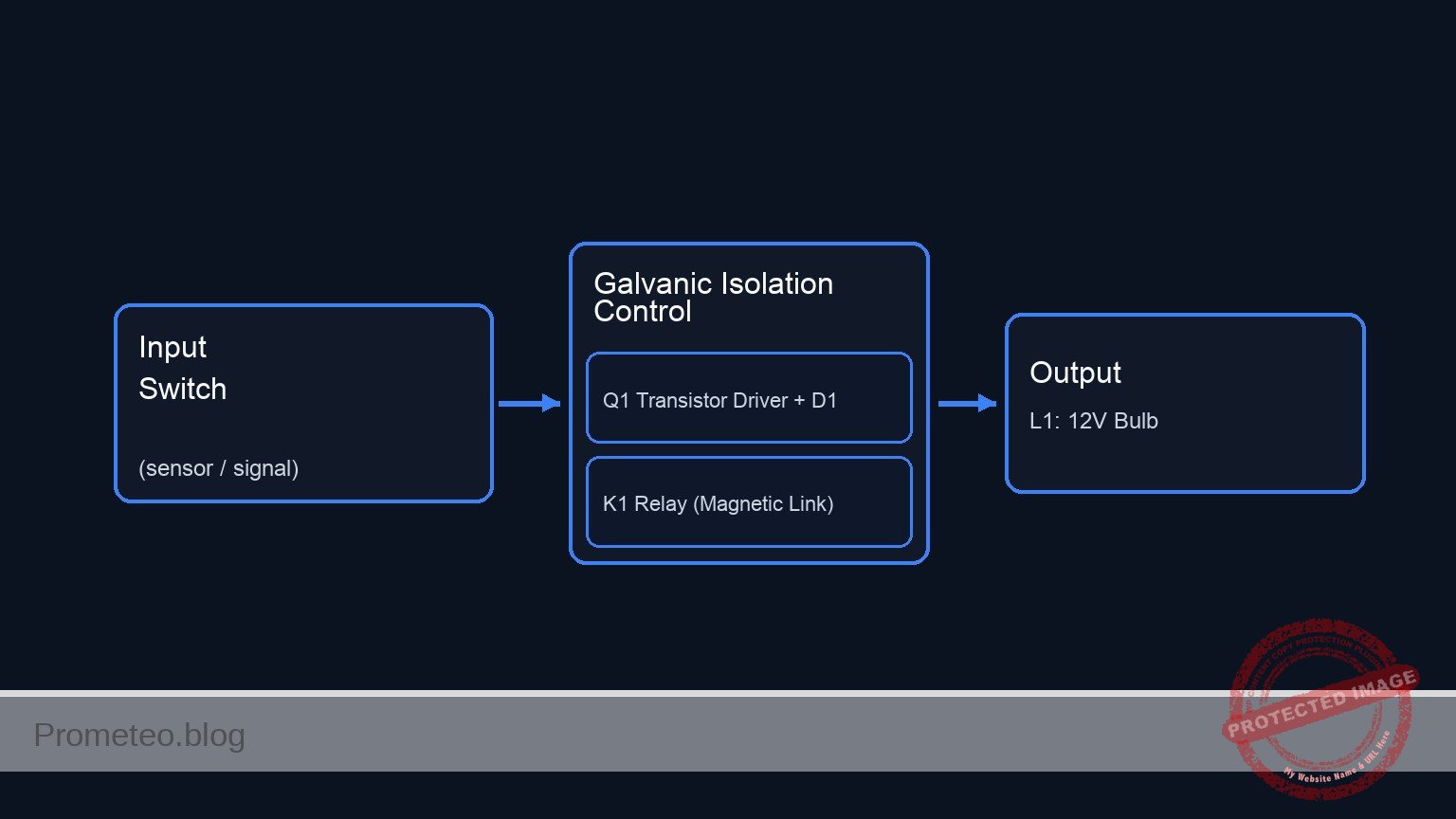

Level: Basic – Control a high-power load using a low-voltage signal via galvanic isolation.

Objective and use case

You will build a driver circuit that uses a small 5 V signal to activate an electromechanical relay, which in turn switches a separate 12 V high-power circuit powering a bulb.

-

Why it is useful:

- Automotive Systems: Allows a low-current ECU signal to switch high-current headlights.

- Safety: Keeps high voltage/current (the load side) physically separated from the sensitive control logic (the user side).

- Interface: Enables microcontrollers (like Arduino/ESP32) to control industrial equipment or AC appliances (simulated here with 12 V).

-

Expected outcome:

- The 12 V bulb turns ON only when the 5 V control switch is closed.

- An audible «click» is heard from the relay component when switching states.

- Measurements: 0 V on the load when the control signal is 0 V; ~12 V on the load when the control signal is 5 V.

-

Target audience: Students dealing with electromechanical interfaces and circuit protection.

Materials

- V1: 5 V DC voltage source, function: Control Logic Supply

- V2: 12 V DC voltage source, function: High Power Load Supply

- S1: SPST Toggle Switch, function: Control trigger

- R1: 1 kΩ resistor, function: Base current limiter for Q1

- Q1: 2N2222 NPN BJT Transistor, function: Relay coil driver

- D1: 1N4007 Diode, function: Flyback protection (snubber)

- K1: 5 V SPST Relay (coil resistance ~70 Ω), function: Galvanic isolation switch

- L1: 12 V / 10 W Incandescent Bulb, function: High power load

Wiring guide

This guide uses specific node names to ensure correct connections in simulation and assembly. The circuit has two isolated sides: the Control Side (Nodes: V_CTRL, 0) and the Load Side (Nodes: V_HV, GND_LOAD).

Control Side (Low Power):

* V1 (+): Connects to Node V_CTRL.

* V1 (-): Connects to Node 0 (Common Ground).

* S1: Connects between V_CTRL and Node V_TRIG.

* R1: Connects between V_TRIG and Node V_BASE.

* Q1 (Base): Connects to Node V_BASE.

* Q1 (Emitter): Connects to Node 0.

* Q1 (Collector): Connects to Node COIL_LOW.

* K1 (Coil pin 1): Connects to Node V_CTRL.

* K1 (Coil pin 2): Connects to Node COIL_LOW.

* D1 (Anode): Connects to Node COIL_LOW.

* D1 (Cathode): Connects to Node V_CTRL (Reverse biased across coil).

Load Side (High Power):

* V2 (+): Connects to Node V_HV.

* V2 (-): Connects to Node GND_LOAD (Isolated from Node 0).

* K1 (Common Contact): Connects to Node V_HV.

* K1 (Normally Open Contact): Connects to Node BULB_IN.

* L1: Connects between Node BULB_IN and Node GND_LOAD.

Conceptual block diagram

Schematic

+-------------------------------------------------------------------------+

| PRACTICAL CASE: HIGH POWER CIRCUIT ISOLATION |

+-------------------------------------------------------------------------+

===========================================================================

PART 1: CONTROL SIDE (5 V Logic)

Nodes: V_CTRL, V_TRIG, V_BASE, COIL_LOW, 0 (GND)

===========================================================================

(Trigger Signal Path)

[ V1: 5 V (+) ] --> [ S1: Switch ] --> [ R1: 1k Ohm ] --> [ Q1: Base ]

|

| (Controls)

v

(Coil Power Path) [ Q1: Collector ]

[ V1: 5 V (+) ] ---------> [ K1: Relay Coil ] --------------> |

[ || D1 Diode ] |

[ (Rev Biased) ] | (Conducts to)

|

v

[ Q1: Emitter ]

|

v

[ Node 0 (GND) ]

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

~ MAGNETIC LINK (GALVANIC ISOLATION) ~

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

===========================================================================

PART 2: LOAD SIDE (12 V High Power)

Nodes: V_HV, BULB_IN, GND_LOAD

===========================================================================

(High Current Path)

[ V2: 12 V (+) ] --> [ K1: Relay Switch ] --> [ L1: 12 V Bulb ] --> [ GND_LOAD ]

[ (COM -> NO) ]

Measurements and tests

Follow these steps to validate the isolation and switching capability:

-

Coil Voltage Test:

- Close switch S1.

- Measure voltage between

V_CTRLandCOIL_LOW. - Result: It should read approximately 5 V (indicating the transistor is sinking current).

-

Load Activation:

- Keep S1 closed.

- Observe L1 (Bulb).

- Result: The bulb illuminates. Measure voltage across L1; it should be ~12 V.

-

Switch Latency (Oscilloscope required):

- Connect Channel 1 to

V_TRIGand Channel 2 toBULB_IN. - Toggle S1 from OFF to ON.

- Result: You will observe a delay (typically 5–15 ms) between the signal rising on Ch1 and power appearing on Ch2. This is the mechanical switching time of the relay armature.

- Connect Channel 1 to

SPICE netlist and simulation

Reference SPICE Netlist (ngspice) — excerptFull SPICE netlist (ngspice)

* High power circuit isolation

*

* This netlist simulates a relay driver circuit with a high-power load.

* It includes a low-voltage control side (5V) and an isolated high-voltage load side (12V).

*

* --- Analysis Setup ---

.tran 10u 10m

.print tran V(V_TRIG) V(BULB_IN) V(COIL_LOW) I(L_K1_COIL)

* --- Control Side (Low Power) ---

* Supply V1: 5V DC

V1 V_CTRL 0 DC 5

* Switch S1: Modeled as a Pulse Voltage Source to simulate user actuation

* Connects to V_TRIG to drive the base resistor.

* Timing: Off for 1ms, On for 4ms, then Off.

V_S1 V_TRIG 0 PULSE(0 5 1m 10u 10u 4m 10m)

* ... (truncated in public view) ...Copy this content into a .cir file and run with ngspice.

* High power circuit isolation

*

* This netlist simulates a relay driver circuit with a high-power load.

* It includes a low-voltage control side (5V) and an isolated high-voltage load side (12V).

*

* --- Analysis Setup ---

.tran 10u 10m

.print tran V(V_TRIG) V(BULB_IN) V(COIL_LOW) I(L_K1_COIL)

* --- Control Side (Low Power) ---

* Supply V1: 5V DC

V1 V_CTRL 0 DC 5

* Switch S1: Modeled as a Pulse Voltage Source to simulate user actuation

* Connects to V_TRIG to drive the base resistor.

* Timing: Off for 1ms, On for 4ms, then Off.

V_S1 V_TRIG 0 PULSE(0 5 1m 10u 10u 4m 10m)

* Resistor R1: 1k Base Current Limiter

R1 V_TRIG V_BASE 1k

* Transistor Q1: 2N2222 NPN Relay Driver

* Connections: Collector=COIL_LOW, Base=V_BASE, Emitter=0

Q1 COIL_LOW V_BASE 0 2N2222MOD

* Relay Coil K1 (Coil Side)

* Modeled as Inductance + Resistance in series between V_CTRL and COIL_LOW

R_K1_COIL V_CTRL INT_COIL 70

L_K1_COIL INT_COIL COIL_LOW 50m

* Diode D1: Flyback protection (Snubber)

* Anode=COIL_LOW, Cathode=V_CTRL

D1 COIL_LOW V_CTRL 1N4007MOD

* --- Load Side (High Power) ---

* Ground Isolation: High resistance path to global ground 0 to prevent singular matrix

R_ISO GND_LOAD 0 100Meg

* Supply V2: 12V DC

V2 V_HV GND_LOAD DC 12

* Relay Contact K1 (Switch Side)

* Modeled as a Voltage Controlled Switch

* Controlled by the voltage across the coil: V(V_CTRL) - V(COIL_LOW)

* Connects V_HV to BULB_IN when coil is energized

S_K1 V_HV BULB_IN V_CTRL COIL_LOW RELAY_SW_MOD

* Load L1: 12V / 10W Bulb

* Resistance ~ 14.4 Ohms (R = V^2 / P = 144 / 10)

R_L1 BULB_IN GND_LOAD 14.4

* --- Component Models ---

* NPN Transistor Model

.model 2N2222MOD NPN(IS=1E-14 VAF=100 BF=200 IKF=0.3 XTB=1.5 BR=3 CJC=8E-12 CJE=25E-12 TR=46.91E-9 TF=411.1E-12 ITF=0.6 VTF=1.7 XTF=3 RB=10 RC=0.3 RE=0.2)

* Diode Model

.model 1N4007MOD D(IS=7.02767n RS=0.0341512 N=1.80803 EG=1.11 XTI=3 BV=1000 IBV=5u CJO=10p VJ=0.7 M=0.5 FC=0.5 TT=100n)

* Relay Switch Model

* Threshold Vt=2.5V (Coil is 5V), Hysteresis Vh=0.5V

.model RELAY_SW_MOD SW(Vt=2.5 Vh=0.5 Ron=0.1 Roff=100Meg)

.op

.endSimulation Results (Transient Analysis)

Show raw data table (4100 rows)

Index time v(v_trig) v(bulb_in) v(coil_low) l_k1_coil#branc 0 0.000000e+00 0.000000e+00 1.722670e-06 5.000000e+00 1.002664e-11 1 1.000000e-07 0.000000e+00 1.722670e-06 5.000000e+00 1.002626e-11 2 2.000000e-07 0.000000e+00 1.722670e-06 5.000000e+00 1.002547e-11 3 4.000000e-07 0.000000e+00 1.722670e-06 5.000000e+00 1.002342e-11 4 8.000000e-07 0.000000e+00 1.722670e-06 5.000000e+00 1.001814e-11 5 1.600000e-06 0.000000e+00 1.722670e-06 5.000000e+00 1.000316e-11 6 3.200000e-06 0.000000e+00 1.722670e-06 5.000000e+00 9.969744e-12 7 6.400000e-06 0.000000e+00 1.722670e-06 5.000000e+00 1.000801e-11 8 1.280000e-05 0.000000e+00 1.722670e-06 5.000000e+00 1.002921e-11 9 2.280000e-05 0.000000e+00 1.722670e-06 5.000000e+00 9.970357e-12 10 3.280000e-05 0.000000e+00 1.722670e-06 5.000000e+00 1.004993e-11 11 4.280000e-05 0.000000e+00 1.722670e-06 5.000000e+00 9.955463e-12 12 5.280000e-05 0.000000e+00 1.722670e-06 5.000000e+00 1.004077e-11 13 6.280000e-05 0.000000e+00 1.722670e-06 5.000000e+00 9.984500e-12 14 7.280000e-05 0.000000e+00 1.722670e-06 5.000000e+00 1.001134e-11 15 8.280000e-05 0.000000e+00 1.722670e-06 5.000000e+00 1.001578e-11 16 9.280000e-05 0.000000e+00 1.722670e-06 5.000000e+00 1.000519e-11 17 1.028000e-04 0.000000e+00 1.722670e-06 5.000000e+00 1.003686e-11 18 1.128000e-04 0.000000e+00 1.722670e-06 5.000000e+00 9.961732e-12 19 1.228000e-04 0.000000e+00 1.722670e-06 5.000000e+00 1.005266e-11 20 1.328000e-04 0.000000e+00 1.722670e-06 5.000000e+00 9.963169e-12 21 1.428000e-04 0.000000e+00 1.722670e-06 5.000000e+00 1.003205e-11 22 1.528000e-04 0.000000e+00 1.722670e-06 5.000000e+00 9.984436e-12 23 1.628000e-04 0.000000e+00 1.722670e-06 5.000000e+00 1.001919e-11 ... (4076 more rows) ...

Common mistakes and how to avoid them

-

Omitting the flyback diode (D1):

- Error: The transistor Q1 fails permanently after a few switches.

- Solution: Always place a diode in reverse bias parallel to the relay coil to absorb the high-voltage spike generated when the magnetic field collapses.

-

Sharing Grounds unintentionally:

- Error: Connecting

GND_LOADto Node0on the breadboard. - Solution: While the circuit will work, you lose galvanic isolation. Keep the high-power return path physically separate from the logic ground.

- Error: Connecting

-

Insufficient Base Current:

- Error: Using a resistor R1 that is too high (e.g., 100 kΩ). The relay does not click or clicks weakly.

- Solution: Ensure the transistor is in saturation. For a 2N2222 driving a standard relay, 1 kΩ is usually sufficient.

Troubleshooting

-

Symptom: Relay clicks, but the bulb does not light up.

- Cause: Issue on the Load Side (Secondary circuit).

- Fix: Check V2 supply, verify the bulb L1 is not burnt, and ensure connections to the Relay COM/NO pins are tight.

-

Symptom: No sound from relay, Bulb OFF.

- Cause: The coil is not energizing.

- Fix: Check voltage at Node

V_BASE. If 0 V, check S1. If ~0.7 V, check if Q1 is installed correctly (E-B-C pinout).

-

Symptom: Transistor gets extremely hot.

- Cause: Coil current is too high for the selected transistor.

- Fix: Verify the relay coil resistance. If it draws >600 mA, the 2N2222 might be underpowered; use a power transistor (e.g., TIP31) or a MOSFET.

Possible improvements and extensions

- Status Indicator: Add a small LED and a 330 Ω resistor in parallel with the Relay Coil to visually indicate when the control signal is active.

- Solid State Upgrade: Replace the mechanical relay (K1) and transistor driver with an Optocoupler and a MOSFET (or Triac for AC) to eliminate mechanical wear and reduce switching latency.

More Practical Cases on Prometeo.blog

Find this product and/or books on this topic on Amazon

As an Amazon Associate, I earn from qualifying purchases. If you buy through this link, you help keep this project running.