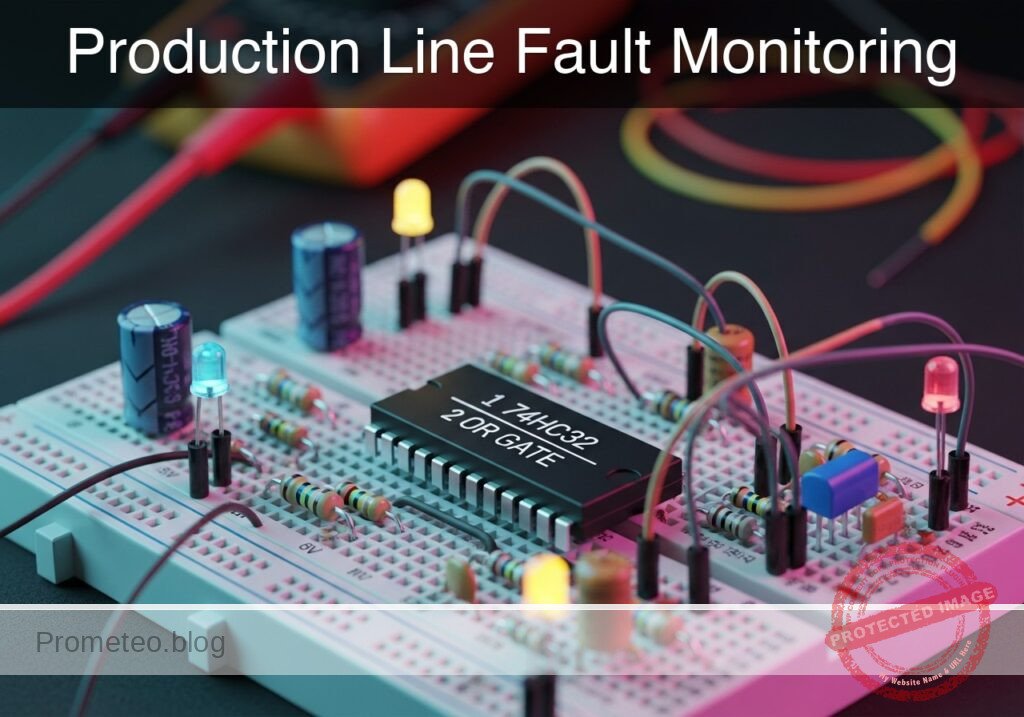

Level: Medium. Implement a safety system that stops a conveyor belt if either the temperature sensor OR the jam sensor detects an anomaly.

Objective and use case

You will build a logic control circuit using an OR gate to combine signals from two distinct safety sensors (Temperature and Optical Jam). When either sensor detects a fault (Logic High), the system will output an active signal to trigger an indicator or stop mechanism.

Why it is useful:

* Industrial Safety: Prevents machinery from operating under dangerous conditions.

* Equipment Protection: Stops motors immediately if they overheat to prevent permanent damage.

* Process Efficiency: Detects physical jams on conveyor belts automatically, reducing waste.

* Redundancy: Allows multiple different error types to trigger the same emergency stop routine.

Expected outcome:

* System Standby: When both sensors are Low (0V), the output LED is OFF.

* Temperature Fault: If the temperature sensor triggers (High/5V), the LED turns ON.

* Jam Fault: If the jam sensor triggers (High/5V), the LED turns ON.

* Critical Failure: If both sensors trigger simultaneously, the LED remains ON.

Target audience and level: Electronics students and hobbyists, Level Medium.

Materials

- V1: 5 V DC power supply, function: Main circuit power.

- U1: 74HC32, function: Quad 2-input OR gate IC.

- S1: SPST Toggle Switch, function: Simulates Temperature Sensor (Open=Normal, Closed=Overheat).

- S2: SPST Toggle Switch, function: Simulates Jam Sensor (Open=Clear, Closed=Jam).

- R1: 10 kΩ resistor, function: Pull-down for Temperature Input.

- R2: 10 kΩ resistor, function: Pull-down for Jam Input.

- R3: 330 Ω resistor, function: Current limiting for indicator LED.

- D1: Red LED, function: Visual Fault Indicator.

Pin-out of the IC used

Selected Chip: 74HC32 (Quad 2-Input OR Gate)

| Pin | Name | Logic function | Connection in this case |

|---|---|---|---|

| 1 | 1A | Input A | Connected to Temperature Sensor (S1) |

| 2 | 1B | Input B | Connected to Jam Sensor (S2) |

| 3 | 1Y | Output | Connected to LED driver (R3 + D1) |

| 7 | GND | Ground | Connected to Power Supply Negative (0V) |

| 14 | VCC | Power (+) | Connected to Power Supply Positive (5V) |

Wiring guide

- VCC: Connect V1 positive terminal to U1 pin 14.

- 0 (GND): Connect V1 negative terminal to U1 pin 7.

- VA (Temp Signal): Connect S1 terminal 2 to U1 pin 1.

- VA (Temp Signal): Connect R1 between U1 pin 1 and 0.

- VCC: Connect S1 terminal 1 to VCC.

- VB (Jam Signal): Connect S2 terminal 2 to U1 pin 2.

- VB (Jam Signal): Connect R2 between U1 pin 2 and 0.

- VCC: Connect S2 terminal 1 to VCC.

- V_OUT: Connect U1 pin 3 to R3 terminal 1.

- LED_NODE: Connect R3 terminal 2 to D1 Anode.

- 0 (GND): Connect D1 Cathode to 0.

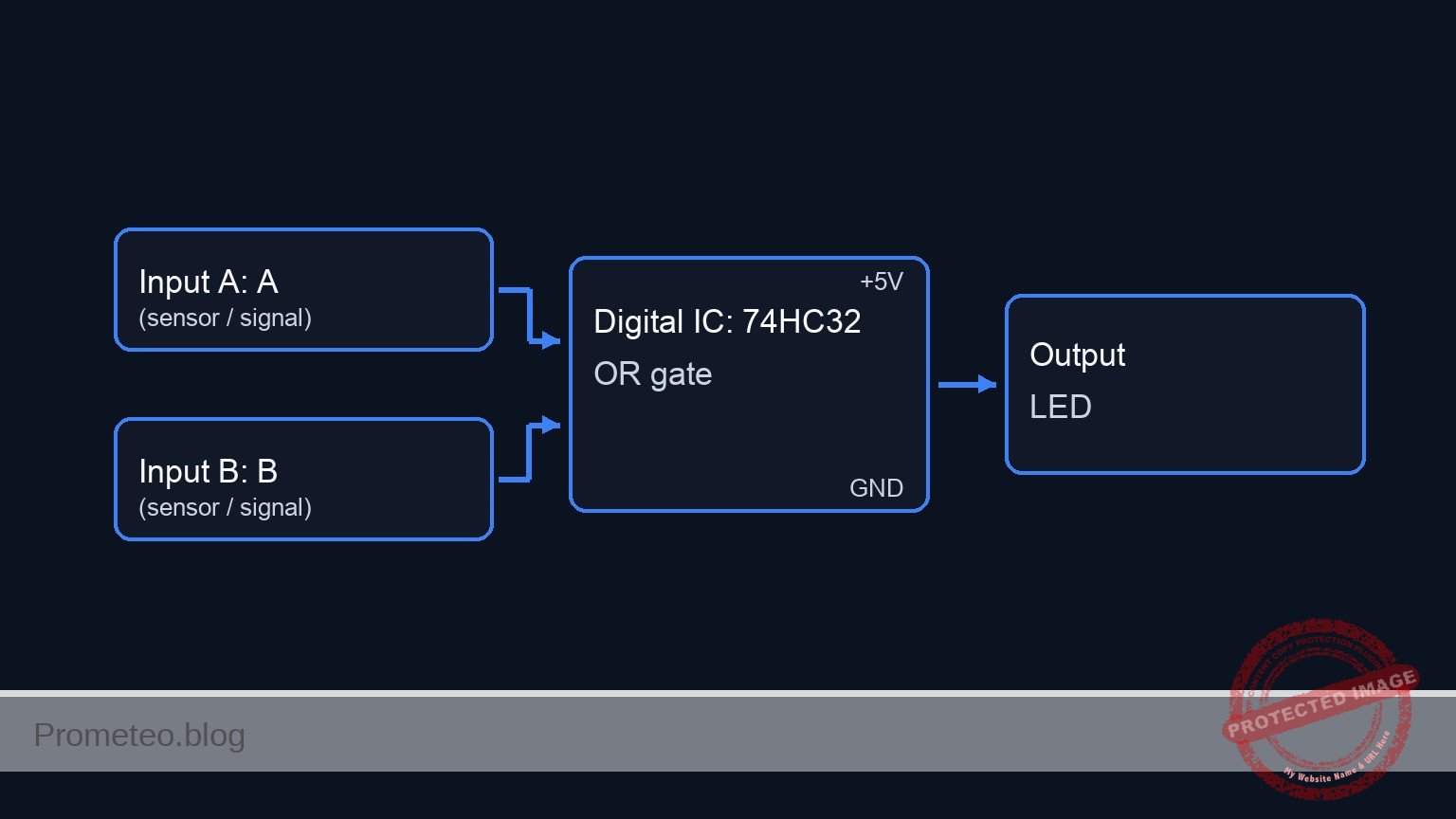

Conceptual block diagram

Schematic

Title: Production Line Fault Monitoring (OR Logic)

[ INPUT SENSORS ] [ LOGIC PROCESSING ] [ VISUAL OUTPUT ]

(Pin 14: VCC)

|

v

[ VCC ] --> [ S1: Temp Switch ] --+--(Pin 1)-->+---------------+

| | |

[ R1: 10k ] | U1: 74HC32 |

| | (OR Gate) |--(Pin 3)--> [ R3: 330 ] --> [ D1: LED ] --> [ GND ]

[ GND ] | |

| |

[ VCC ] --> [ S2: Jam Switch ] --+--(Pin 2)-->+---------------+

| ^

[ R2: 10k ] |

| (Pin 7: GND)

[ GND ]

Truth table

This circuit utilizes positive logic (Active High).

| Sensor A (Temp) | Sensor B (Jam) | Output (Fault Indicator) | LED State |

|---|---|---|---|

| Low (0) | Low (0) | Low (0) | OFF |

| Low (0) | High (1) | High (1) | ON |

| High (1) | Low (0) | High (1) | ON |

| High (1) | High (1) | High (1) | ON |

Measurements and tests

- Standby Check: Ensure both switches S1 and S2 are open. Measure voltage at U1 Pin 3 relative to GND. It should be ~0 V. LED should be OFF.

- Temperature Fault Simulation: Close S1 while keeping S2 open. Measure voltage at Pin 1 (Input A). It should be 5 V. The Output Pin 3 should go to High (~5 V) and the LED must light up.

- Jam Fault Simulation: Open S1 and close S2. Measure voltage at Pin 2 (Input B). It should be 5 V. The LED must light up.

- Simultaneous Fault: Close both S1 and S2. The LED must remain ON.

SPICE netlist and simulation

Reference SPICE Netlist (ngspice) — excerptFull SPICE netlist (ngspice)

* Practical case: Production Line Fault Monitoring

* --- Component Models ---

* Generic Red LED Model

.model DLED D (IS=1e-14 N=2 RS=10 BV=5 IBV=10u CJO=10p)

* --- Subcircuits ---

* 74HC32 Quad 2-input OR Gate

* Pinout: 1=InputA, 2=InputB, 3=Output, 7=GND, 14=VCC

* Implemented using a robust behavioral source with continuous functions

.subckt 74HC32 1 2 3 7 14

* Logic: Output = VCC if (A > 2.5V OR B > 2.5V)

* Using sigmoid function for smooth convergence: S(x) = 1/(1+exp(-k*(x-thresh)))

* max(V(1), V(2)) selects the higher voltage to compare against threshold (2.5V)

B_OR 3 7 V = V(14) * (1 / (1 + exp(-20 * (max(V(1), V(2)) - 2.5))))

.ends

* --- Main Power Supply ---

* V1: 5V DC Supply

* Wiring: Positive -> Node 14 (VCC), Negative -> Node 0 (GND)

V1 14 0 DC 5

* --- Input Sensors (Simulated Switches) ---

* S1: Temperature Sensor Switch

* Wiring: Connects VCC to VA (Pin 1). Modeled as Pulse Source to simulate toggling.

* Logic Sequence: High (Overheat) / Low (Normal)

VS1 VA 0 PULSE(0 5 0 1u 1u 200u 400u)

* S2: Jam Sensor Switch

* Wiring: Connects VCC to VB (Pin 2). Modeled as Pulse Source with faster period.

* ... (truncated in public view) ...Copy this content into a .cir file and run with ngspice.

* Practical case: Production Line Fault Monitoring

* --- Component Models ---

* Generic Red LED Model

.model DLED D (IS=1e-14 N=2 RS=10 BV=5 IBV=10u CJO=10p)

* --- Subcircuits ---

* 74HC32 Quad 2-input OR Gate

* Pinout: 1=InputA, 2=InputB, 3=Output, 7=GND, 14=VCC

* Implemented using a robust behavioral source with continuous functions

.subckt 74HC32 1 2 3 7 14

* Logic: Output = VCC if (A > 2.5V OR B > 2.5V)

* Using sigmoid function for smooth convergence: S(x) = 1/(1+exp(-k*(x-thresh)))

* max(V(1), V(2)) selects the higher voltage to compare against threshold (2.5V)

B_OR 3 7 V = V(14) * (1 / (1 + exp(-20 * (max(V(1), V(2)) - 2.5))))

.ends

* --- Main Power Supply ---

* V1: 5V DC Supply

* Wiring: Positive -> Node 14 (VCC), Negative -> Node 0 (GND)

V1 14 0 DC 5

* --- Input Sensors (Simulated Switches) ---

* S1: Temperature Sensor Switch

* Wiring: Connects VCC to VA (Pin 1). Modeled as Pulse Source to simulate toggling.

* Logic Sequence: High (Overheat) / Low (Normal)

VS1 VA 0 PULSE(0 5 0 1u 1u 200u 400u)

* S2: Jam Sensor Switch

* Wiring: Connects VCC to VB (Pin 2). Modeled as Pulse Source with faster period.

* Logic Sequence: High (Jam) / Low (Clear)

VS2 VB 0 PULSE(0 5 0 1u 1u 100u 200u)

* --- Pull-down Resistors ---

* R1: 10k Pull-down for Temp Input

R1 VA 0 10k

* R2: 10k Pull-down for Jam Input

R2 VB 0 10k

* --- Logic IC U1 ---

* U1: 74HC32 Quad OR Gate

* Connections per wiring guide:

* Pin 1 (A) -> VA

* Pin 2 (B) -> VB

* Pin 3 (Y) -> V_OUT

* Pin 7 (GND) -> 0

* Pin 14 (VCC) -> 14

XU1 VA VB V_OUT 0 14 74HC32

* --- Output Indicator ---

* R3: 330 Ohm Current Limiting Resistor

R3 V_OUT LED_NODE 330

* D1: Red LED Visual Indicator

* Anode -> LED_NODE, Cathode -> GND

D1 LED_NODE 0 DLED

* --- Analysis Directives ---

* Transient analysis to capture truth table states (00, 01, 10, 11)

.tran 1u 400u

* Print required voltages for verification

.print tran V(VA) V(VB) V(V_OUT) V(LED_NODE)

* Calculate DC operating point

.op

.endSimulation Results (Transient Analysis)

Show raw data table (906 rows)

Index time v(va) v(vb) v(v_out) 0 0.000000e+00 0.000000e+00 0.000000e+00 9.643749e-22 1 1.000000e-08 5.000000e-02 5.000000e-02 1.928750e-21 2 2.000000e-08 1.000000e-01 1.000000e-01 5.242886e-21 3 4.000000e-08 2.000000e-01 2.000000e-01 2.137746e-20 4 8.000000e-08 4.000000e-01 4.000000e-01 2.632654e-19 5 1.600000e-07 8.000000e-01 8.000000e-01 2.587285e-17 6 3.200000e-07 1.600000e+00 1.600000e+00 7.614990e-08 7 4.700575e-07 2.350288e+00 2.350288e+00 2.384318e-01 8 6.126008e-07 3.063004e+00 3.063004e+00 4.999936e+00 9 7.041960e-07 3.520980e+00 3.520980e+00 5.000000e+00 10 7.932149e-07 3.966074e+00 3.966074e+00 5.000000e+00 11 9.007723e-07 4.503862e+00 4.503862e+00 5.000000e+00 12 1.000000e-06 5.000000e+00 5.000000e+00 5.000000e+00 13 1.021511e-06 5.000000e+00 5.000000e+00 5.000000e+00 14 1.064534e-06 5.000000e+00 5.000000e+00 5.000000e+00 15 1.150580e-06 5.000000e+00 5.000000e+00 5.000000e+00 16 1.322672e-06 5.000000e+00 5.000000e+00 5.000000e+00 17 1.666856e-06 5.000000e+00 5.000000e+00 5.000000e+00 18 2.355224e-06 5.000000e+00 5.000000e+00 5.000000e+00 19 3.355224e-06 5.000000e+00 5.000000e+00 5.000000e+00 20 4.355224e-06 5.000000e+00 5.000000e+00 5.000000e+00 21 5.355224e-06 5.000000e+00 5.000000e+00 5.000000e+00 22 6.355224e-06 5.000000e+00 5.000000e+00 5.000000e+00 23 7.355224e-06 5.000000e+00 5.000000e+00 5.000000e+00 ... (882 more rows) ...

Common mistakes and how to avoid them

- Leaving Inputs Floating: Failing to install pull-down resistors (R1, R2) causes the inputs to «float» and pick up noise, causing the LED to flicker or stay ON randomly. Solution: Always use 10kΩ pull-down resistors on CMOS inputs connected to switches.

- Missing Current Limiting Resistor: Connecting the LED directly to the 74HC32 output pin without R3. Solution: Ensure R3 (330Ω) is in series with the LED to prevent burning out the IC or the LED.

- Confusing Pinout: Treating the 74HC32 like a different logic chip (e.g., 74HC02 NOR) due to similar package shape. Solution: Always verify the datasheet pin diagram; Pin 3 is output for the first gate on the 74HC32.

Troubleshooting

- LED is always ON: Check if pull-down resistors R1 and R2 are connected to Ground. If inputs are disconnected, they float High.

- LED is very dim: The resistor R3 might be too high (e.g., 10kΩ instead of 330Ω) or the power supply voltage is below 3V.

- Nothing happens when switches close: Verify that U1 Pin 14 is connected to 5V and Pin 7 is connected to GND. Check switch continuity.

- Logic is inverted (LED OFF when fault occurs): You may have accidentally used a NOR gate or wired the LED active-low (Anode to VCC, Cathode to Output).

Possible improvements and extensions

- Latching Alarm: Add an SR Flip-Flop or a feedback loop so that once a fault is detected, the alarm stays ON until a manual «Reset» button is pressed, even if the sensor returns to normal.

- Audible Alert: Connect a transistor driver and a 5V active buzzer in parallel with the LED to provide an audio warning for noisy factory environments.

More Practical Cases on Prometeo.blog

Find this product and/or books on this topic on Amazon

As an Amazon Associate, I earn from qualifying purchases. If you buy through this link, you help keep this project running.