Level: Medium. Design a control circuit that compares light levels from two sensors to orient a motor towards the brightest light source.

Objective and use case

This practical case guides you through building an analog control loop that automatically orients a mechanism towards a light source using photoresistors (LDRs) and operational amplifiers. You will construct a «sun seeker» that actively balances two light inputs to drive a motor in the corresponding direction.

- Real-world applications:

- Solar Energy: Increases photovoltaic panel efficiency by keeping panels perpendicular to the sun throughout the day.

- Robotics: Enables light-seeking behaviors (phototaxis) in autonomous robots.

- Home Automation: Controls smart blinds to regulate room temperature based on sunlight intensity.

- Expected outcome:

- When the light source is balanced, the motor remains stationary.

- When LDR1 is shaded, the voltage difference triggers the motor to spin Clockwise (CW).

- When LDR2 is shaded, the motor spins Counter-Clockwise (CCW).

- Target audience: Electronics students familiar with voltage dividers and OpAmps.

Materials

- V1: 9 V DC power supply (Power source).

- R1: Photoresistor (LDR), function: Left light sensor.

- R2: Photoresistor (LDR), function: Right light sensor.

- R3: 10 kΩ resistor, function: Voltage divider bottom leg for R1.

- R4: 10 kΩ resistor, function: Voltage divider bottom leg for R2.

- U1: LM358, function: Dual Operational Amplifier (Comparators).

- U2: L293D, function: H-Bridge Motor Driver IC.

- M1: 9 V DC Gear Motor, function: Tracking actuator.

- C1: 100 nF capacitor, function: Power supply decoupling.

Wiring guide

This circuit uses two parallel voltage dividers compared by two OpAmps to determine motor direction.

- Power Supply:

- Connect

V1positive terminal to nodeVCC. - Connect

V1negative terminal to nodeGND(0). -

Connect

C1betweenVCCandGND. -

Sensors (Dual Voltage Divider):

- Connect

R1(LDR Left) betweenVCCand nodeVA(Sensor Voltage A). - Connect

R3betweenVAandGND. - Connect

R2(LDR Right) betweenVCCand nodeVB(Sensor Voltage B). -

Connect

R4betweenVBandGND. -

Comparators (LM358 – U1):

- Comparator A (Turn Right/CW Logic):

- Connect

U1Non-inverting input (+) to nodeVA. - Connect

U1Inverting input (-) to nodeVB. - Connect

U1Output A to nodeSIG_CW.

- Connect

- Comparator B (Turn Left/CCW Logic):

- Connect

U1Non-inverting input (+) to nodeVB. - Connect

U1Inverting input (-) to nodeVA. - Connect

U1Output B to nodeSIG_CCW.

- Connect

-

Connect

U1VCC pin toVCCand GND pin toGND. -

Motor Driver (L293D – U2):

- Connect

U2Input 1 to nodeSIG_CW. - Connect

U2Input 2 to nodeSIG_CCW. - Connect

U2Enable 1 pin toVCC. - Connect

U2Output 1 to nodeM_POS. - Connect

U2Output 2 to nodeM_NEG. - Connect

U2VCC1 (Logic) and VCC2 (Power) toVCC. -

Connect

U2GND pins toGND. -

Actuator:

- Connect

M1(Motor) between nodesM_POSandM_NEG.

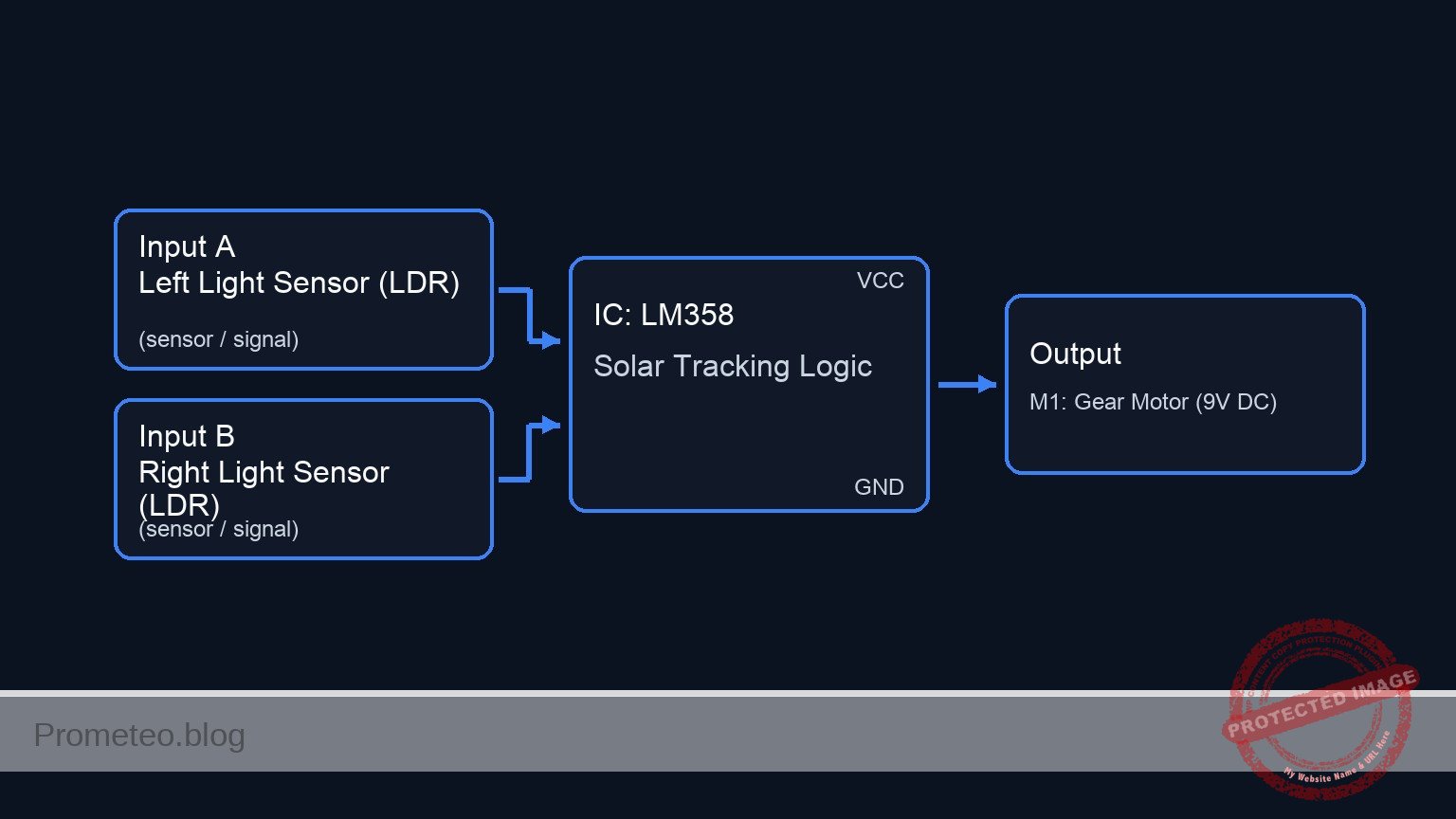

Conceptual block diagram

Schematic

[ INPUTS / SENSORS ] [ LOGIC / PROCESSING ] [ ACTUATOR ]

[ Power Supply Block ]

[ Source: V1 (9 V) ] --(VCC/GND Power)--> (Distributes to all ICs and Sensors)

[ Filter: C1 (100nF) ]

[ U1: LM358 Dual OpAmp ]

| |

[ Left Light Sensor ] | Comparator A (Logic) |

[ Top: R1 (LDR) ] --(Signal VA)->| Input: VA > VB ? |--(SIG_CW)--->+

[ Bot: R3 (10k Ohm) ] | Output: Turn CW | |

| | |

| | v

| Comparator B (Logic) | [ U2: L293D H-Bridge ]

[ Right Light Sensor ] | Input: VB > VA ? | | |

[ Top: R2 (LDR) ] --(Signal VB)->| Output: Turn CCW | | Input 1: CW Sig |

[ Bot: R4 (10k Ohm) ] | | | Input 2: CCW Sig |===(High Current)==> [ M1: Gear Motor ]

+----------+-----------+ | Enable: VCC | (9 V DC)

| | VCC1/VCC2: 9 V |

+--(SIG_CCW)------>| GND: Common |

+--------------------+

Measurements and tests

Follow these steps to validate the tracker logic:

-

Static Equilibrium Test:

- Expose both LDRs to ambient light equally.

- Measure the voltage at node

VAandVB. They should be approximately equal. - Measure

SIG_CWandSIG_CCW. Both should be Low (approx. 0 V) or balanced, keeping the motor stopped.

-

Left Shade Simulation:

- Cover

R1(Left LDR) with your hand. - Observation: The resistance of

R1increases, causing voltage atVAto drop. - Logic Check: Since

VB>VA, Comparator B (Non-inverting =VB) should go High (SIG_CCW≈ VCC). - Actuator: The motor should spin Counter-Clockwise.

- Cover

-

Right Shade Simulation:

- Expose

R1to light and coverR2(Right LDR). - Observation: The resistance of

R2increases, causing voltage atVBto drop. - Logic Check: Since

VA>VB, Comparator A (Non-inverting =VA) should go High (SIG_CW≈ VCC). - Actuator: The motor should spin Clockwise.

- Expose

SPICE netlist and simulation

Reference SPICE Netlist (ngspice) — excerptFull SPICE netlist (ngspice)

* Single-axis Solar Tracker Simulation

* Based on Practical Electronics Breadboard Case

* --- Power Supply ---

* V1: 9 V DC power supply

V1 VCC 0 DC 9V

* C1: 100 nF capacitor (Decoupling)

C1 VCC 0 100nF

* --- Dynamic Light Stimulus (Virtual Control) ---

* This source simulates the position of the sun moving from Left to Right.

* 0V = Light on Left Sensor, 5V = Light on Right Sensor.

* Sweeps linearly from 0V to 5V over 100ms.

V_LIGHT LIGHT_POS 0 PWL(0 0 100m 5)

* --- Sensors (LDRs) ---

* Modeled as voltage-dependent resistors controlled by LIGHT_POS.

* R1 (Left LDR): Resistance increases as Light moves Right (LIGHT_POS increases).

* Range: 1k (Bright) to 50k (Dark).

R1 VCC VA R = '1k + 49k * (V(LIGHT_POS)/5)'

* ... (truncated in public view) ...Copy this content into a .cir file and run with ngspice.

* Single-axis Solar Tracker Simulation

* Based on Practical Electronics Breadboard Case

* --- Power Supply ---

* V1: 9 V DC power supply

V1 VCC 0 DC 9V

* C1: 100 nF capacitor (Decoupling)

C1 VCC 0 100nF

* --- Dynamic Light Stimulus (Virtual Control) ---

* This source simulates the position of the sun moving from Left to Right.

* 0V = Light on Left Sensor, 5V = Light on Right Sensor.

* Sweeps linearly from 0V to 5V over 100ms.

V_LIGHT LIGHT_POS 0 PWL(0 0 100m 5)

* --- Sensors (LDRs) ---

* Modeled as voltage-dependent resistors controlled by LIGHT_POS.

* R1 (Left LDR): Resistance increases as Light moves Right (LIGHT_POS increases).

* Range: 1k (Bright) to 50k (Dark).

R1 VCC VA R = '1k + 49k * (V(LIGHT_POS)/5)'

* R2 (Right LDR): Resistance decreases as Light moves Right.

* Range: 50k (Dark) to 1k (Bright).

R2 VCC VB R = '1k + 49k * (1 - V(LIGHT_POS)/5)'

* --- Voltage Divider Bottom Legs ---

* R3: 10 kΩ resistor for R1

R3 VA 0 10k

* R4: 10 kΩ resistor for R2

R4 VB 0 10k

* --- Comparators (U1: LM358) ---

* U1 is a Dual OpAmp. We define a subcircuit matching the 8-pin DIP pinout.

* Pinout: 1=OutA, 2=In-A, 3=In+A, 4=GND, 5=In+B, 6=In-B, 7=OutB, 8=VCC

* Wiring Guide:

* Comparator A (CW): (+) VA, (-) VB -> Out SIG_CW

* Comparator B (CCW): (+) VB, (-) VA -> Out SIG_CCW

XU1 SIG_CW VB VA 0 VB VA SIG_CCW VCC LM358_DIP8

* --- Motor Driver (U2: L293D) ---

* U2 is an H-Bridge Driver. We define a subcircuit for the used pins.

* Pinout used: 1=EN1, 2=IN1, 3=OUT1, 4/5=GND, 6=OUT2, 7=IN2, 8=VCC2, 16=VCC1

* Wiring Guide:

* IN1=SIG_CW, IN2=SIG_CCW, OUT1=M_POS, OUT2=M_NEG, EN1=VCC

XU2 VCC SIG_CW M_POS 0 0 M_NEG SIG_CCW VCC VCC L293D_BRIDGE

* --- Actuator (M1: 9V DC Gear Motor) ---

* Modeled as a resistive/inductive load.

R_M1 M_POS M_INT 20

L_M1 M_INT M_NEG 5mH

* --- Subcircuit Definitions ---

.subckt LM358_DIP8 OUTA INMA INPA GND INPB INMB OUTB VCC

* Comparator A Behavior (Sigmoid for convergence)

* Output swings approx 0V to VCC-1.5V

B_OUTA OUTA 0 V = (V(VCC)-1.5) / (1 + exp(-50*(V(INPA)-V(INMA)))) + 0.05

* Comparator B Behavior

B_OUTB OUTB 0 V = (V(VCC)-1.5) / (1 + exp(-50*(V(INPB)-V(INMB)))) + 0.05

.ends

.subckt L293D_BRIDGE EN1 IN1 OUT1 GND1 GND2 OUT2 IN2 VCC2 VCC1

* Logic Threshold approx 2.0V.

* Output Voltage ~ VCC2 - 1.4V drop.

* Enable Logic

B_EN node_en 0 V = 1 / (1 + exp(-50*(V(EN1)-2.0)))

* Output 1 (M_POS)

B_O1 OUT1 0 V = V(node_en) * (1/(1+exp(-50*(V(IN1)-2.0)))) * (V(VCC2)-1.4)

* Output 2 (M_NEG)

B_O2 OUT2 0 V = V(node_en) * (1/(1+exp(-50*(V(IN2)-2.0)))) * (V(VCC2)-1.4)

.ends

* --- Simulation Directives ---

.op

* Transient analysis: 100ms duration to capture the full light sweep

.tran 100u 100m

* Print signals to verify logic:

* VA/VB: Sensor Voltages

* SIG_CW/CCW: Comparator Logic Outputs

* M_POS/M_NEG: Motor Drive Voltages

.print tran V(VA) V(VB) V(SIG_CW) V(SIG_CCW) V(M_POS) V(M_NEG) V(LIGHT_POS)

.endSimulation Results (Transient Analysis)

Show raw data table (3024 rows)

Index time v(va) v(vb) v(sig_cw) 0 0.000000e+00 8.181818e+00 1.500000e+00 7.550000e+00 1 1.000000e-06 8.181454e+00 1.500012e+00 7.550000e+00 2 2.000000e-06 8.181089e+00 1.500025e+00 7.550000e+00 3 4.000000e-06 8.180361e+00 1.500049e+00 7.550000e+00 4 8.000000e-06 8.178903e+00 1.500098e+00 7.550000e+00 5 1.600000e-05 8.175990e+00 1.500196e+00 7.550000e+00 6 3.200000e-05 8.170168e+00 1.500392e+00 7.550000e+00 7 6.400000e-05 8.158542e+00 1.500784e+00 7.550000e+00 8 1.280000e-04 8.135365e+00 1.501569e+00 7.550000e+00 9 2.280000e-04 8.099394e+00 1.502797e+00 7.550000e+00 10 3.280000e-04 8.063833e+00 1.504028e+00 7.550000e+00 11 4.280000e-04 8.028586e+00 1.505260e+00 7.550000e+00 12 5.280000e-04 7.993645e+00 1.506495e+00 7.550000e+00 13 6.280000e-04 7.959008e+00 1.507732e+00 7.550000e+00 14 7.280000e-04 7.924669e+00 1.508970e+00 7.550000e+00 15 8.280000e-04 7.890626e+00 1.510211e+00 7.550000e+00 16 9.280000e-04 7.856873e+00 1.511454e+00 7.550000e+00 17 1.028000e-03 7.823409e+00 1.512699e+00 7.550000e+00 18 1.128000e-03 7.790228e+00 1.513945e+00 7.550000e+00 19 1.228000e-03 7.757327e+00 1.515194e+00 7.550000e+00 20 1.328000e-03 7.724703e+00 1.516445e+00 7.550000e+00 21 1.428000e-03 7.692352e+00 1.517698e+00 7.550000e+00 22 1.528000e-03 7.660271e+00 1.518953e+00 7.550000e+00 23 1.628000e-03 7.628457e+00 1.520211e+00 7.550000e+00 ... (3000 more rows) ...

Common mistakes and how to avoid them

-

LDRs placed too close together:

- Symptom: The system is insensitive and requires extreme light angles to react.

- Solution: Mount the LDRs with a physical blinder (a piece of cardboard or plastic) between them so a shadow is cast on one LDR when the light is not perfectly centered.

-

Driving the motor directly from OpAmps:

- Symptom: The motor hums but doesn’t turn, or the OpAmp overheats and fails.

- Solution: Always use a current driver stage like the L293D or a transistor H-Bridge. OpAmps cannot supply the current required by motors (typically >100 mA).

-

Lack of Deadband (Jittering):

- Symptom: The motor constantly vibrates back and forth when the light is centered.

- Solution: This basic topology is a «bang-bang» controller. In advanced designs, add hysteresis resistors to the OpAmps to create a small voltage window where the motor remains off.

Troubleshooting

- Motor spins in the wrong direction:

- Cause: The motor polarity is reversed relative to the sensor placement.

- Fix: Swap the connections of

M1(M_POS and M_NEG) OR physically swap the positions ofR1andR2.

- Motor runs continuously even in equal light:

- Cause: Large tolerance difference between the two LDRs or fixed resistors (R3/R4).

- Fix: Replace one fixed resistor (e.g., R3) with a 10k trim potentiometer to calibrate the bridge balance manually.

- Nothing happens when light changes:

- Cause: L293D Enable pin not connected high.

- Fix: Ensure the Enable pin of the driver is connected to VCC.

Possible improvements and extensions

- Sensitivity Control: Replace the fixed resistors R3 and R4 with a single multi-turn potentiometer. Connect the wiper to ground and the ends to the LDRs to allow fine-tuning of the center point.

- Solar Power Integration: Replace V1 with a small solar panel and a charging circuit to make the tracker self-sustaining.

More Practical Cases on Prometeo.blog

Find this product and/or books on this topic on Amazon

As an Amazon Associate, I earn from qualifying purchases. If you buy through this link, you help keep this project running.