Level: Medium. Implement an industrial safety circuit that activates an alarm only when both temperature and pressure sensors exceed critical safety limits.

Objective and use case

In this session, you will build a conditional logic circuit using an LM393 comparator to digitize analog sensor signals and a 74HC08 AND gate to process the safety logic.

- Industrial Boiler Safety: Prevents catastrophic failure by detecting when a boiler is both overheating and over-pressurized.

- Hydraulic Systems: Monitors fluid states to prevent pump damage or pipe bursts during high-stress operations.

- Chemical Reactor Monitoring: Ensures reaction conditions remain within safe zones, triggering emergency cooling only when multiple critical variables spike.

Expected outcome:

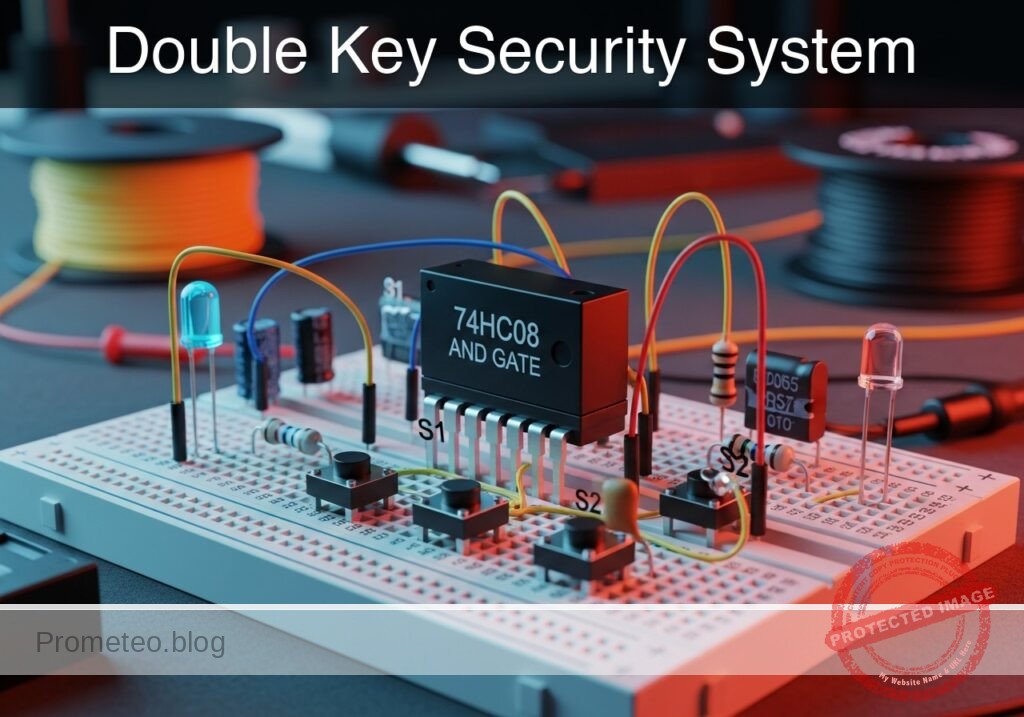

* Safe State: LED remains OFF if only one or neither variable exceeds the limit.

* Critical State: Red LED turns ON (Logic High) only when Temp > Limit AND Pressure > Limit.

* Logic Level: The 74HC08 output shifts from ~0V to ~5V.

* Target Audience: Engineering students and hobbyists familiar with operational amplifiers/comparators and basic digital logic.

Materials

- V1: 5 V DC supply

- U1: 74HC08, function: Quad 2-Input AND Gate

- U2: LM393, function: Dual Differential Comparator

- RT1: 10 kΩ NTC thermistor, function: Temperature sensor

- R1: 10 kΩ resistor, function: Voltage divider bottom for NTC

- RP1: 10 kΩ linear potentiometer, function: Pressure sensor simulator

- RP2: 10 kΩ potentiometer, function: Temperature reference threshold (V_REF_T)

- RP3: 10 kΩ potentiometer, function: Pressure reference threshold (V_REF_P)

- R2: 4.7 kΩ resistor, function: Pull-up for Comparator A output (required for LM393)

- R3: 4.7 kΩ resistor, function: Pull-up for Comparator B output (required for LM393)

- R4: 330 Ω resistor, function: LED current limiting

- D1: Red LED, function: Critical Alert indicator

Pin-out of the IC used

Selected Chip: 74HC08 (Quad 2-Input AND Gate)

| Pin | Name | Logic function | Connection in this case |

|---|---|---|---|

| 1 | 1A | Input A | Connected to Temperature Comparator Output |

| 2 | 1B | Input B | Connected to Pressure Comparator Output |

| 3 | 1Y | Output | Connected to LED (via R4) |

| 7 | GND | Ground | Connected to 0V supply rail |

| 14 | VCC | Power Supply | Connected to +5V supply rail |

Note: The LM393 Comparator is also used but the logic decision happens in the 74HC08.

Wiring guide

Construct the circuit using the following node connections:

- Power Rail: Connect

V1positive terminal to nodeVCCand negative terminal to node0(GND). Connect pin 14 ofU1and pin 8 ofU2toVCC. Connect pin 7 ofU1and pin 4 ofU2to0. - Temperature Sensor Input (

V_TEMP): ConnectRT1betweenVCCandV_TEMP. ConnectR1betweenV_TEMPand0. (As Temp rises, resistance drops,V_TEMPrises). - Pressure Sensor Input (

V_PRESS): Connect the wiper ofRP1to nodeV_PRESS. Connect the outer legs ofRP1toVCCand0. - Reference Thresholds: Connect the wiper of

RP2to nodeV_REF_T(Temp Limit). Connect the wiper ofRP3to nodeV_REF_P(Pressure Limit). - Comparator Stage (Digitization):

- Connect

V_TEMPtoU2pin 3 (Non-inverting input A). - Connect

V_REF_TtoU2pin 2 (Inverting input A). - Connect

V_PRESStoU2pin 5 (Non-inverting input B). - Connect

V_REF_PtoU2pin 6 (Inverting input B).

- Connect

- Comparator Outputs (

LOGIC_TandLOGIC_P):- Connect

U2pin 1 (Output A) to nodeLOGIC_T. Connect pull-up resistorR2betweenLOGIC_TandVCC. - Connect

U2pin 7 (Output B) to nodeLOGIC_P. Connect pull-up resistorR3betweenLOGIC_PandVCC.

- Connect

- Logic Gate:

- Connect

LOGIC_TtoU1pin 1 (Input 1A). - Connect

LOGIC_PtoU1pin 2 (Input 1B). - Connect

U1pin 3 (Output 1Y) to nodeALERT.

- Connect

- Indicator: Connect

R4betweenALERTand the anode ofD1. Connect the cathode ofD1to0.

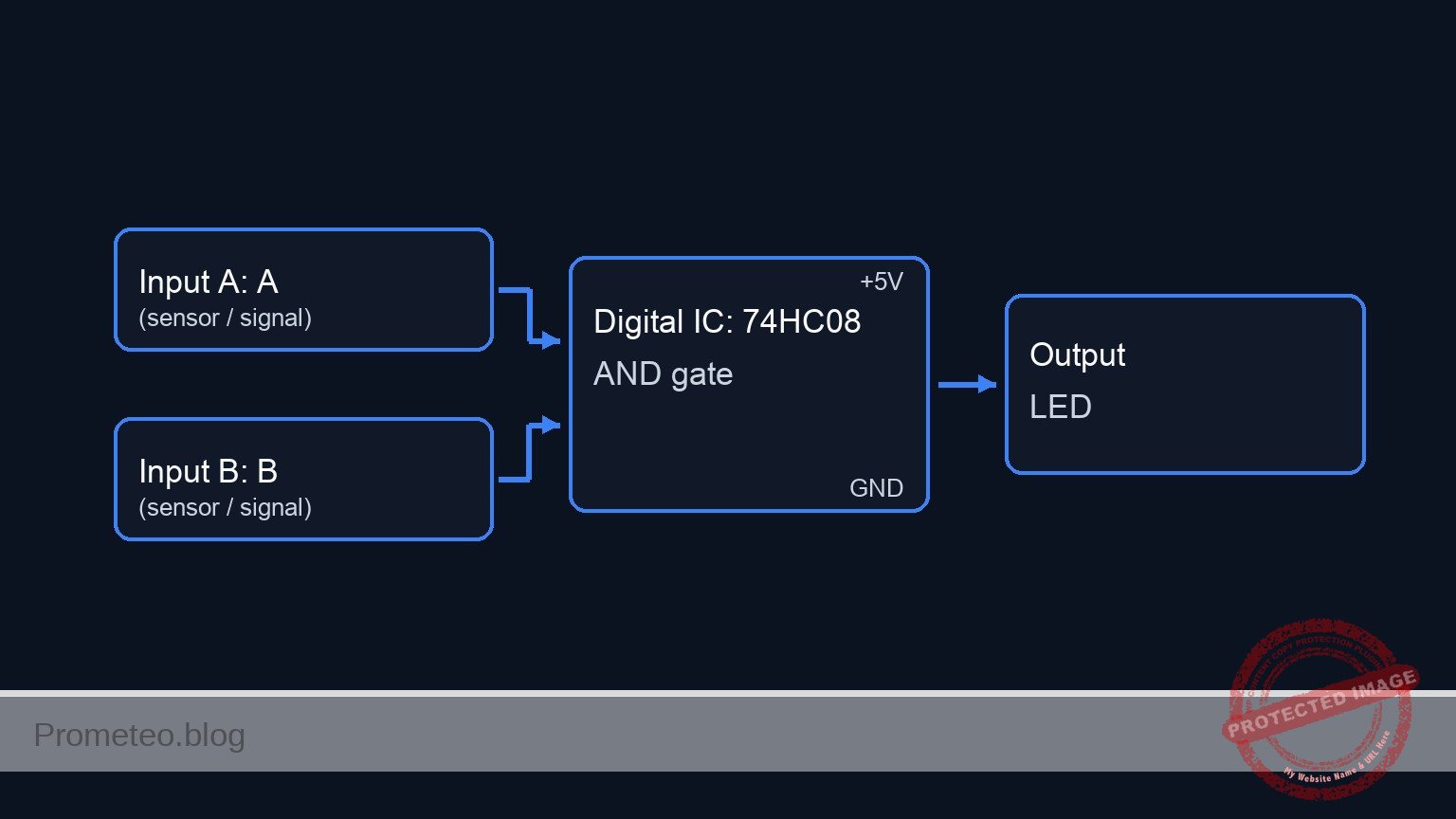

Conceptual block diagram

Schematic

[ ANALOG INPUTS ] [ COMPARATORS ] [ LOGIC GATE ] [ OUTPUT ]

[ Temp Sensor (RT1/R1) ] --(V_TEMP)---->+------------------+

| U2: Comparator A |

| (LM393) |--(LOGIC_T)-->+

[ Temp Ref Pot (RP2) ] --(V_REF_T)--->| w/ Pull-up R2 | |

+------------------+ |

v

+----------------+

| U1: AND Gate |

| (74HC08) |--(ALERT)--> [ Resistor R4 ] --> [ LED D1 ] --> GND

+----------------+

^

+------------------+ |

[ Press Sensor (RP1) ] --(V_PRESS)--->| U2: Comparator B | |

| (LM393) |--(LOGIC_P)-->+

[ Press Ref Pot (RP3) ] --(V_REF_P)--->| w/ Pull-up R3 |

+------------------+

Truth table

This table represents the logic states at the inputs of the 74HC08 (after the comparator stage) and the final output.

| Sensor: Temperature | Sensor: Pressure | Input 1A (Temp Alert) | Input 1B (Press Alert) | Output 1Y (System Alarm) | LED State |

|---|---|---|---|---|---|

| Low (< Ref) | Low (< Ref) | 0 | 0 | 0 | OFF |

| Low (< Ref) | High (> Ref) | 0 | 1 | 0 | OFF |

| High (> Ref) | Low (< Ref) | 1 | 0 | 0 | OFF |

| High (> Ref) | High (> Ref) | 1 | 1 | 1 | ON |

Measurements and tests

- Calibrate Thresholds: Use a voltmeter to set

V_REF_T(atRP2wiper) to 3.0V andV_REF_P(atRP3wiper) to 3.0V. - Test Temperature Logic: Heat

RT1(or simulate by shorting R1 slightly) untilV_TEMP> 3.0V. MeasureLOGIC_T; it should be High (~5V). Verify LED is OFF (since Pressure is Low). - Test Pressure Logic: Turn

RP1untilV_PRESS> 3.0V. MeasureLOGIC_P; it should be High (~5V). - System Alert Test: Create a condition where

V_TEMP> 3.0V ANDV_PRESS> 3.0V simultaneously.- Measure Voltage at

ALERT(U1 Pin 3): Expected ~5V. - Visual: The Red LED

D1must turn ON.

- Measure Voltage at

SPICE netlist and simulation

Reference SPICE Netlist (ngspice) — excerptFull SPICE netlist (ngspice)

* Practical case: Temperature and Pressure Monitoring

* --- Power Supply ---

* V1: 5 V DC supply

V1 VCC 0 DC 5

* --- Sensors and Inputs ---

* Temperature Sensor (RT1 NTC + R1 Divider)

* RT1: 10 kΩ NTC thermistor (Modeled as R_RT1)

* Connected between VCC and V_TEMP

R_RT1 VCC V_TEMP 10k

* R1: 10 kΩ resistor (Voltage divider bottom)

* Connected between V_TEMP and 0 (GND)

R1 V_TEMP 0 10k

* Pressure Sensor (RP1 Potentiometer)

* RP1: 10 kΩ linear potentiometer

* Modeled as two resistors (Top/Bot) representing the wiper position.

* Outer legs to VCC and 0, wiper to V_PRESS.

R_RP1_TOP VCC V_PRESS 5k

R_RP1_BOT V_PRESS 0 5k

* --- Dynamic Stimuli (Simulation) ---

* These voltage sources drive the sensor nodes to simulate physical changes

* over time, verifying the logic thresholds (sweeping 1V to 4V).

* They effectively override the static resistor dividers for transient analysis.

V_TEMP_STIM V_TEMP 0 PULSE(1 4 0.5m 100u 100u 1m 3m)

V_PRESS_STIM V_PRESS 0 PULSE(1 4 1m 100u 100u 1.5m 4m)

* --- Reference Thresholds ---

* ... (truncated in public view) ...Copy this content into a .cir file and run with ngspice.

* Practical case: Temperature and Pressure Monitoring

* --- Power Supply ---

* V1: 5 V DC supply

V1 VCC 0 DC 5

* --- Sensors and Inputs ---

* Temperature Sensor (RT1 NTC + R1 Divider)

* RT1: 10 kΩ NTC thermistor (Modeled as R_RT1)

* Connected between VCC and V_TEMP

R_RT1 VCC V_TEMP 10k

* R1: 10 kΩ resistor (Voltage divider bottom)

* Connected between V_TEMP and 0 (GND)

R1 V_TEMP 0 10k

* Pressure Sensor (RP1 Potentiometer)

* RP1: 10 kΩ linear potentiometer

* Modeled as two resistors (Top/Bot) representing the wiper position.

* Outer legs to VCC and 0, wiper to V_PRESS.

R_RP1_TOP VCC V_PRESS 5k

R_RP1_BOT V_PRESS 0 5k

* --- Dynamic Stimuli (Simulation) ---

* These voltage sources drive the sensor nodes to simulate physical changes

* over time, verifying the logic thresholds (sweeping 1V to 4V).

* They effectively override the static resistor dividers for transient analysis.

V_TEMP_STIM V_TEMP 0 PULSE(1 4 0.5m 100u 100u 1m 3m)

V_PRESS_STIM V_PRESS 0 PULSE(1 4 1m 100u 100u 1.5m 4m)

* --- Reference Thresholds ---

* RP2: 10 kΩ potentiometer (Temperature Reference)

* Configured as divider, wiper to V_REF_T. Set to ~2.5V.

R_RP2_TOP VCC V_REF_T 5k

R_RP2_BOT V_REF_T 0 5k

* RP3: 10 kΩ potentiometer (Pressure Reference)

* Configured as divider, wiper to V_REF_P. Set to ~2.5V.

R_RP3_TOP VCC V_REF_P 5k

R_RP3_BOT V_REF_P 0 5k

* --- Comparator Stage (U2: LM393) ---

* U2: Dual Differential Comparator

* Connections based on Wiring Guide:

* Comp A (Temp): In+ (3)=V_TEMP, In- (2)=V_REF_T, Out (1)=LOGIC_T

* Comp B (Press): In+ (5)=V_PRESS, In- (6)=V_REF_P, Out (7)=LOGIC_P

* Power: VCC (8), GND (4)

XU2 LOGIC_T V_REF_T V_TEMP 0 V_PRESS V_REF_P LOGIC_P VCC LM393

* Pull-up resistors (Required for Open Collector Outputs)

* R2: 4.7 kΩ pull-up for Comparator A

R2 VCC LOGIC_T 4.7k

* R3: 4.7 kΩ pull-up for Comparator B

R3 VCC LOGIC_P 4.7k

* --- Logic Stage (U1: 74HC08) ---

* U1: Quad 2-Input AND Gate

* Connections:

* Gate 1: Input 1A (1)=LOGIC_T, Input 1B (2)=LOGIC_P, Output 1Y (3)=ALERT

* Power: VCC (14), GND (7)

* Unused inputs (4,5,9,10,12,13) connected to 0 (GND) to prevent floating.

XU1 LOGIC_T LOGIC_P ALERT 0 0 0 0 0 0 0 0 0 0 VCC 74HC08

* --- Indicator ---

* R4: 330 Ω resistor (LED current limiting)

R4 ALERT LED_A 330

* D1: Red LED (Cathode to GND)

D1 LED_A 0 DLED

* --- Models and Subcircuits ---

* LED Model

.model DLED D(IS=1e-14 N=1.7 RS=10)

* LM393 Subcircuit (Behavioral Open Collector)

.subckt LM393 1 2 3 4 5 6 7 8

* Pinout: 1=OutA, 2=InA-, 3=InA+, 4=GND, 5=InB+, 6=InB-, 7=OutB, 8=VCC

* Logic: If In+ > In-, Output is High-Z (Pull-up High).

* If In+ < In-, Output is Low (GND).

* Implementation uses Voltage Controlled Switch to GND.

* Control V = In(-) - In(+). If V > 0 (In- > In+), Switch Closed (Low).

B_A_CTRL 10 0 V = V(2) - V(3)

S_A 1 4 10 0 SW_OC

B_B_CTRL 20 0 V = V(6) - V(5)

S_B 7 4 20 0 SW_OC

.model SW_OC SW(Vt=0 Vh=1m Ron=10 Roff=100Meg)

.ends LM393

* 74HC08 Subcircuit (Behavioral AND Gate)

.subckt 74HC08 1 2 3 4 5 6 7 8 9 10 11 12 13 14

* Pinout: 1=1A, 2=1B, 3=1Y, 7=GND, 14=VCC ...

* Gate 1 Logic: Output High (VCC) if V(1)>2.5 and V(2)>2.5

B_Y1 3 7 V = V(14) * (1 / (1 + exp(-50*(V(1)-2.5)))) * (1 / (1 + exp(-50*(V(2)-2.5))))

.ends 74HC08

* --- Simulation Directives ---

.tran 10u 5ms

.print tran V(V_TEMP) V(V_PRESS) V(LOGIC_T) V(LOGIC_P) V(ALERT)

.endSimulation Results (Transient Analysis)

Show raw data table (1124 rows)

Index time v(v_temp) v(v_press) v(logic_t) 0 0.000000e+00 1.000000e+00 1.000000e+00 1.061571e-02 1 1.000000e-07 1.000000e+00 1.000000e+00 1.061571e-02 2 2.000000e-07 1.000000e+00 1.000000e+00 1.061571e-02 3 4.000000e-07 1.000000e+00 1.000000e+00 1.061571e-02 4 8.000000e-07 1.000000e+00 1.000000e+00 1.061571e-02 5 1.600000e-06 1.000000e+00 1.000000e+00 1.061571e-02 6 3.200000e-06 1.000000e+00 1.000000e+00 1.061571e-02 7 6.400000e-06 1.000000e+00 1.000000e+00 1.061571e-02 8 1.280000e-05 1.000000e+00 1.000000e+00 1.061571e-02 9 2.280000e-05 1.000000e+00 1.000000e+00 1.061571e-02 10 3.280000e-05 1.000000e+00 1.000000e+00 1.061571e-02 11 4.280000e-05 1.000000e+00 1.000000e+00 1.061571e-02 12 5.280000e-05 1.000000e+00 1.000000e+00 1.061571e-02 13 6.280000e-05 1.000000e+00 1.000000e+00 1.061571e-02 14 7.280000e-05 1.000000e+00 1.000000e+00 1.061571e-02 15 8.280000e-05 1.000000e+00 1.000000e+00 1.061571e-02 16 9.280000e-05 1.000000e+00 1.000000e+00 1.061571e-02 17 1.028000e-04 1.000000e+00 1.000000e+00 1.061571e-02 18 1.128000e-04 1.000000e+00 1.000000e+00 1.061571e-02 19 1.228000e-04 1.000000e+00 1.000000e+00 1.061571e-02 20 1.328000e-04 1.000000e+00 1.000000e+00 1.061571e-02 21 1.428000e-04 1.000000e+00 1.000000e+00 1.061571e-02 22 1.528000e-04 1.000000e+00 1.000000e+00 1.061571e-02 23 1.628000e-04 1.000000e+00 1.000000e+00 1.061571e-02 ... (1100 more rows) ...

Common mistakes and how to avoid them

- Missing Pull-up Resistors on Comparators: The LM393 has open-collector outputs. If you omit

R2andR3, the inputs to the 74HC08 will float or remain low, preventing the circuit from working. Solution: Always install pull-ups (4.7kΩ to 10kΩ) from the output pin to VCC. - Incorrect NTC Wiring: Connecting the NTC to ground and the fixed resistor to VCC creates a voltage that drops as temperature rises. Solution: Connect the NTC to VCC and the fixed resistor to Ground to ensure voltage increases with temperature, matching the non-inverting comparator logic.

- Floating Inputs on 74HC08: Leaving unused inputs on the logic chip connected to nothing can cause noise and higher power consumption. Solution: Connect unused inputs (e.g., pins 4, 5, 9, 10, 12, 13) to GND.

Troubleshooting

- LED never turns ON: Check if

R2orR3are missing. Without them, the AND gate inputs see Logic 0. Verify the orientation of the LED. - LED is always ON: Check

RP2andRP3. If the reference voltage is set to 0V, the sensors will always appear «High» relative to the reference. - Erratic/Flickering LED: The voltage at the comparator inputs might be hovering exactly at the threshold. This creates noise. Adding a hysteresis feedback resistor can solve this, but ensuring clean power connections usually suffices for basic tests.

Possible improvements and extensions

- Add Hysteresis: Connect a high-value resistor (e.g., 100kΩ) between the comparator output and the non-inverting input. This prevents the «chattering» effect when sensor values hover near the threshold.

- Audible Alarm: Connect a buzzer with a transistor driver (like a 2N2222) to the output of the 74HC08 alongside the LED for an audible warning in a noisy industrial environment.

More Practical Cases on Prometeo.blog

Find this product and/or books on this topic on Amazon

As an Amazon Associate, I earn from qualifying purchases. If you buy through this link, you help keep this project running.