Level: Basic. Demonstrate how moving a magnet through a coil generates an electromotive force (EMF).

Objective and use case

In this practical case, you will construct a fundamental electromagnetic induction demonstrator using a hand-wound copper coil and a high-strength neodymium magnet. You will observe how kinetic energy is converted into electrical energy via Faraday’s Law of Induction.

Why it is useful:

* Power Generation: This mechanism illustrates the core principle behind electric generators, alternators, and wind turbines.

* Audio Technology: This is the operating principle for dynamic microphones and electric guitar pickups (transducers).

* Sensors: Used in automotive ABS speed sensors and industrial position sensors.

* Wireless Charging: Demonstrates the basics of magnetic coupling used in phone chargers.

Expected outcome:

* A measurable voltage spike (positive or negative) on the multimeter when the magnet moves relative to the coil.

* The LED flashes briefly when the magnet is moved rapidly, indicating a voltage peak exceeding the diode’s forward voltage (~1.8 V).

* Reversing the direction of the magnet’s movement reverses the polarity of the induced voltage.

Target audience: Students and hobbyists introducing themselves to Faraday’s Law and passive components.

Materials

- L1: Air core coil (approx. 500–1000 turns of enameled copper wire), function: induction element.

- MAG1: Cylindrical Neodymium magnet (fit to pass inside L1), function: source of magnetic flux.

- D1: Red LED, function: indicator for positive phase induction.

- D2: Green LED, function: indicator for negative phase induction (connected in anti-parallel).

- M1: Multimeter (set to 200 mV or 2 V DC range), function: voltage monitor.

Wiring guide

The circuit consists of the coil connected directly to the indicators in parallel. We define the coil terminals as nodes COIL_A and COIL_B.

- L1: Connects between node

COIL_Aand nodeCOIL_B. - D1: Anode connects to

COIL_A; Cathode connects toCOIL_B. - D2: Anode connects to

COIL_B; Cathode connects toCOIL_A(anti-parallel to D1). - M1: Positive probe connects to

COIL_A; Negative probe connects toCOIL_B.

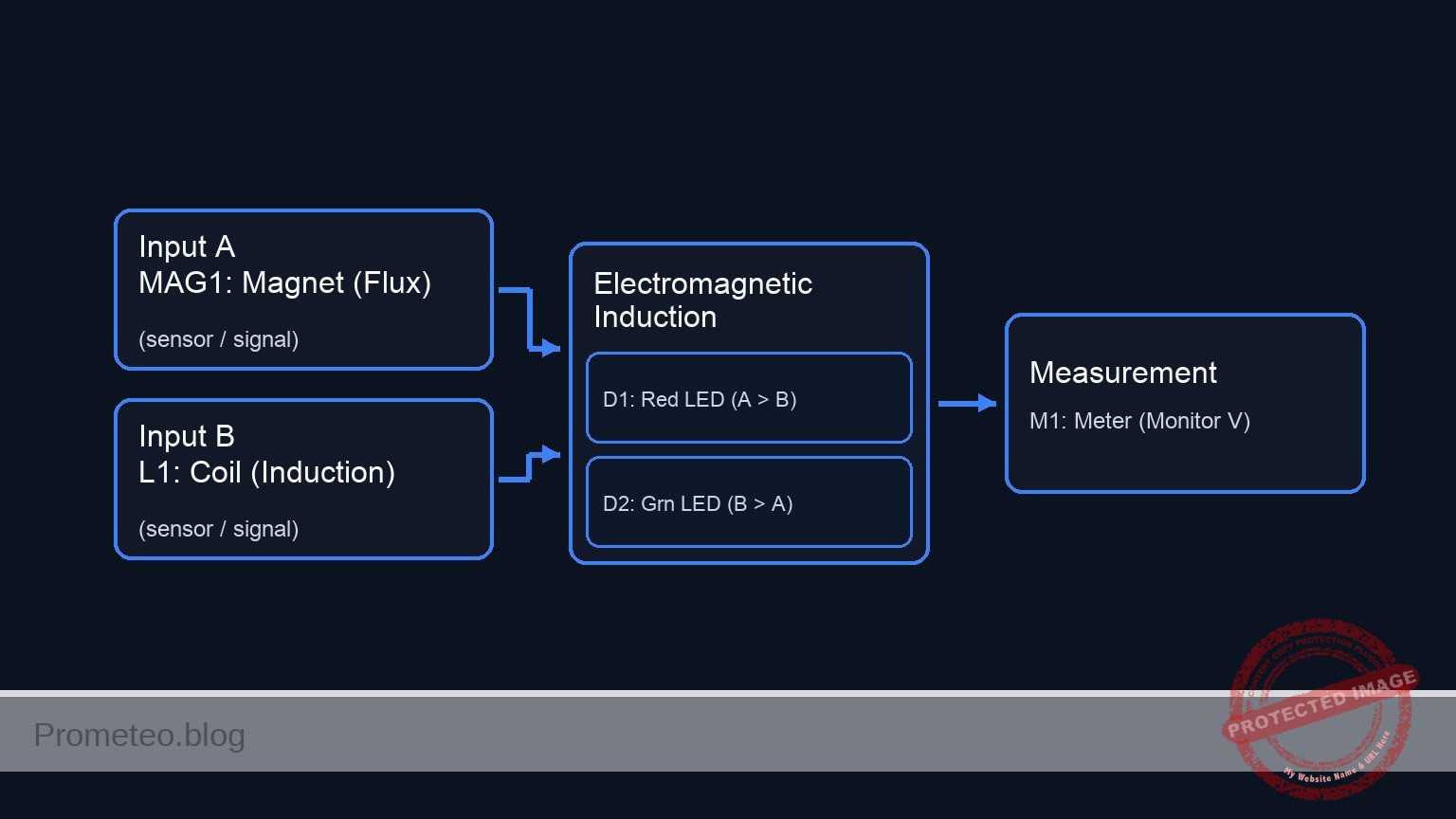

Conceptual block diagram

Schematic

markdown

Title: Practical case: Voltage induction by magnetic movement

[ INPUT / SOURCE ] [ DISTRIBUTION RAILS ] [ OUTPUT / LOADS ]

(Node A: Top Rail)

/------------------------------------------------------------------>

| | | |

[ MAG1: Magnet ] --(Flux)--> [ L1: Coil ] | (Anode) | (Cathode) | (+)

| v v v

| [ D1: Red LED ] [ D2: Grn LED ] [ M1: Meter ]

| (Lights if A > B) (Lights if B > A) (Monitor V)

| | | |

| | (Cathode) | (Anode) | (-)

\ v v v

\------------------------------------------------------------------>

(Node B: Bottom Rail)

Measurements and tests

- Static Test: Place the magnet inside the coil and hold it completely still. The multimeter should read 0 V, and no LEDs should light up. This confirms that a changing magnetic field is required.

- Slow Insertion: Set the multimeter to the lowest DC voltage range (e.g., 200 mV). Slowly push the magnet into the coil. Observe a small voltage reading (e.g., +10 to +50 mV).

- Fast Action: Quickly thrust the magnet into the coil. You should see a significantly higher voltage spike (potentially > 1 V) and D1 (Red) may flash briefly.

- Reverse Motion: Quickly pull the magnet out of the coil. The voltage polarity on the multimeter will flip (negative sign), and D2 (Green) should flash.

- Oscillation: Move the magnet back and forth rapidly inside the coil. The LEDs should flicker alternately, demonstrating the generation of Alternating Current (AC).

SPICE netlist and simulation

Reference SPICE Netlist (ngspice) — excerptFull SPICE netlist (ngspice)

* Practical case: Voltage induction by magnetic movement

.width out=256

*

* Description:

* Simulation of a magnet moving through a coil, inducing voltage to drive two antiparallel LEDs.

*

* Nodes:

* COIL_A : Hot terminal of the coil (Multimeter +)

* COIL_B : Reference terminal of the coil (Multimeter -, Grounded)

*

* Note: The physical "Coil" is modeled as a series combination of an EMF Voltage Source (V_MAG1),

* a Resistor (R_WIRE), and the Inductor (L1).

* --- Power / Reference ---

* Grounding COIL_B as per Multimeter negative probe convention

V_REF COIL_B 0 0

* --- Magnetic Induction Source (MAG1) ---

* Simulating the changing magnetic flux from MAG1 as an AC voltage source.

* 3V Peak, 5Hz (Simulates shaking the magnet)

* ... (truncated in public view) ...Copy this content into a .cir file and run with ngspice.

* Practical case: Voltage induction by magnetic movement

.width out=256

*

* Description:

* Simulation of a magnet moving through a coil, inducing voltage to drive two antiparallel LEDs.

*

* Nodes:

* COIL_A : Hot terminal of the coil (Multimeter +)

* COIL_B : Reference terminal of the coil (Multimeter -, Grounded)

*

* Note: The physical "Coil" is modeled as a series combination of an EMF Voltage Source (V_MAG1),

* a Resistor (R_WIRE), and the Inductor (L1).

* --- Power / Reference ---

* Grounding COIL_B as per Multimeter negative probe convention

V_REF COIL_B 0 0

* --- Magnetic Induction Source (MAG1) ---

* Simulating the changing magnetic flux from MAG1 as an AC voltage source.

* 3V Peak, 5Hz (Simulates shaking the magnet)

V_MAG1 N_EMF COIL_B SIN(0 3 5)

* --- Coil Assembly (L1) ---

* Internal wire resistance

R_WIRE N_EMF N_L1 5

* The physical inductance L1

L1 N_L1 COIL_A 10m

* --- Indicators ---

* D1: Red LED (Indicates Positive Phase)

* Anode: COIL_A, Cathode: COIL_B

D1 COIL_A COIL_B D_RED

* D2: Green LED (Indicates Negative Phase)

* Anode: COIL_B, Cathode: COIL_A

D2 COIL_B COIL_A D_GREEN

* --- Multimeter (M1) ---

* Modeled as the voltage difference V(COIL_A) - V(COIL_B)

* (Implicit in the node voltages)

* --- Models ---

* Generic LED Models

.model D_RED D(IS=1e-18 N=2 RS=10 BV=5)

.model D_GREEN D(IS=1e-18 N=2.5 RS=10 BV=5)

* --- Simulation Directives ---

.op

* Transient analysis: 1ms step, 500ms duration (2.5 cycles at 5Hz)

.tran 1m 500m

* --- Output ---

* Monitoring the induced voltage at COIL_A

.print tran V(COIL_A) I(L1)Simulation Results (Transient Analysis)

Show raw data table (522 rows)

Index time v(coil_a) l1#branch 0 0.000000e+00 4.375392e-35 -8.75078e-36 1 1.000000e-05 9.424778e-04 1.884985e-15 2 2.000000e-05 1.884955e-03 3.769970e-15 3 4.000000e-05 3.769910e-03 7.539938e-15 4 8.000000e-05 7.539814e-03 1.507987e-14 5 1.600000e-04 1.507958e-02 3.015936e-14 6 3.200000e-04 3.015878e-02 6.031856e-14 7 6.400000e-04 6.031451e-02 1.206316e-13 8 1.280000e-03 1.206046e-01 2.412214e-13 9 2.280000e-03 2.147012e-01 4.294658e-13 10 3.280000e-03 3.085859e-01 6.175653e-13 11 4.280000e-03 4.021661e-01 8.067202e-13 12 5.280000e-03 4.953494e-01 1.005111e-12 13 6.280000e-03 5.880438e-01 1.262566e-12 14 7.280000e-03 6.801579e-01 1.873422e-12 15 8.280000e-03 7.716008e-01 4.548512e-12 16 9.280000e-03 8.622822e-01 1.907006e-11 17 1.028000e-02 9.521126e-01 1.003825e-10 18 1.128000e-02 1.041003e+00 5.511221e-10 19 1.228000e-02 1.128867e+00 3.003086e-09 20 1.328000e-02 1.215616e+00 1.605415e-08 21 1.428000e-02 1.301164e+00 8.389370e-08 22 1.528000e-02 1.385424e+00 4.276266e-07 23 1.628000e-02 1.468291e+00 2.121308e-06 ... (498 more rows) ...

Common mistakes and how to avoid them

- Using weak magnets: Standard black ferrite magnets are often too weak to generate visible voltage on an LED. Solution: Use rare-earth Neodymium magnets.

- Moving too slowly: Faraday’s Law (V = – N · d\Phi / dt) depends on the rate of change. Solution: Move the magnet as quickly as possible to maximize the voltage spike.

- Insulation issues: Enameled wire has a clear coating that blocks electricity. Solution: Ensure the ends of the coil wire are sanded or scraped down to bare copper before connecting to the LEDs or multimeter.

Troubleshooting

- Symptom: Multimeter shows voltage, but LEDs never light up.

- Cause: The induced voltage is lower than the LED forward voltage threshold (~1.8 V).

- Fix: Add more turns to the coil (increase $N$) or move the magnet faster.

- Symptom: No reading on the multimeter even with fast movement.

- Cause: Open circuit or poor connection at the coil tips.

- Fix: Check continuity (resistance mode) across the coil terminals; it should read a few Ohms, not infinite.

- Symptom: Voltage reading is erratic or hard to see.

- Cause: Digital multimeters have a slow sample rate.

- Fix: Use the «Max/Min» hold function if available, or use an analog (needle) multimeter which responds better to transient pulses.

Possible improvements and extensions

- Shake Flashlight: Add a bridge rectifier (4 diodes) and a large capacitor (e.g., 1000 µF) to store the energy generated by shaking the magnet, allowing the LED to stay lit for a few seconds after motion stops.

- Core Comparison: Insert an iron bolt inside the coil (making it an iron-core inductor) and move a magnet near the head of the bolt to observe how the ferromagnetic core concentrates the magnetic flux and affects induction.

More Practical Cases on Prometeo.blog

Find this product and/or books on this topic on Amazon

As an Amazon Associate, I earn from qualifying purchases. If you buy through this link, you help keep this project running.