Level: Basic. Implement a logic safety stop for a water pump using a NAND gate.

Objective and use case

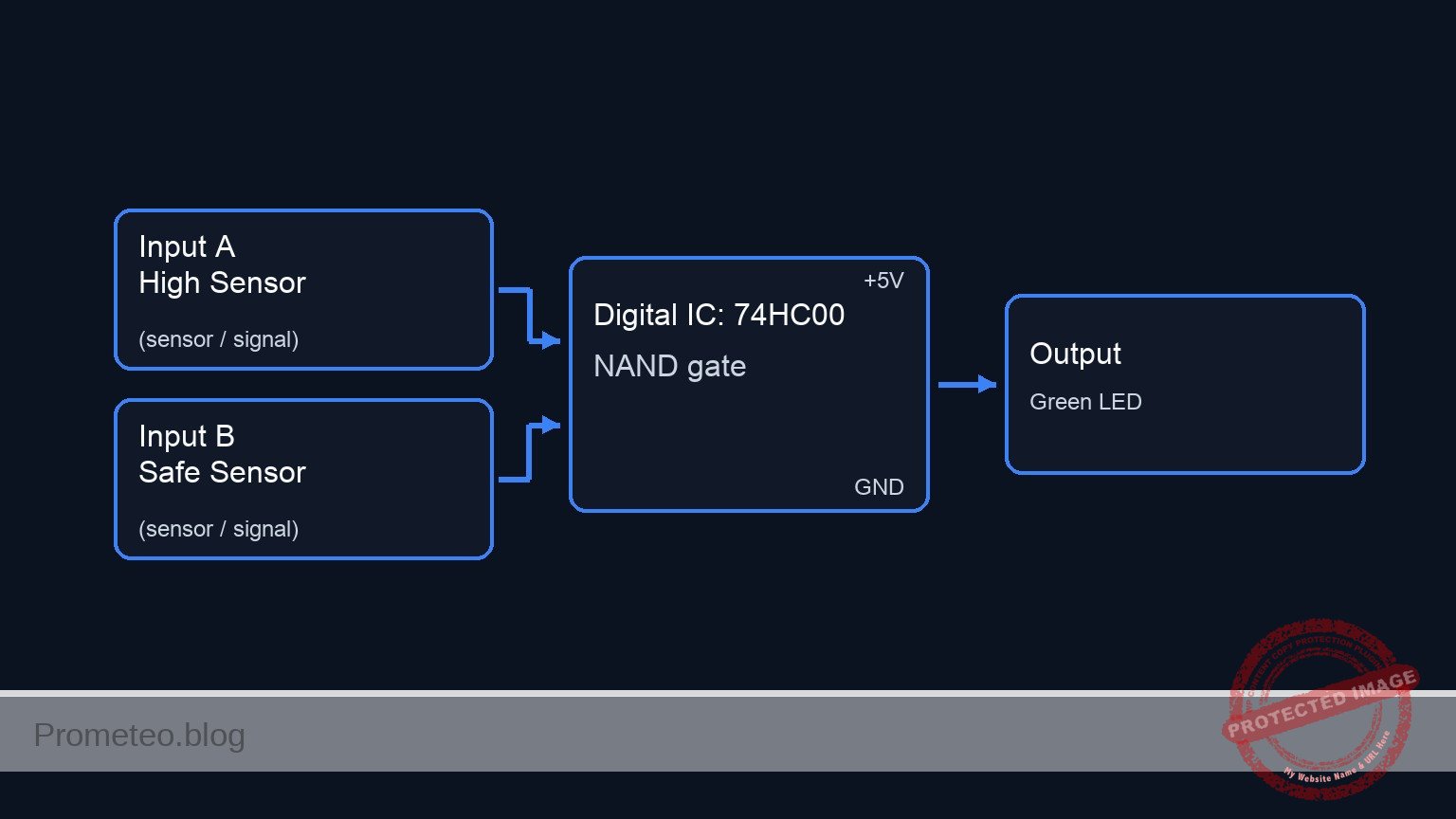

In this session, you will build a digital safety circuit using a 74HC00 NAND gate. The circuit monitors two liquid level sensors and automatically cuts power to a «pump» (simulated by an LED) only when both sensors indicate the tank is dangerously full.

- Industrial tank filling: Prevents chemical spills by ensuring redundant sensors must agree before triggering an emergency shutdown.

- Sump pump systems: Prevents motor burnout or overflow by managing logic states between high-water and critical-overflow marks.

- Home automation: Simple logic for reservoir management without needing a microcontroller.

Expected outcome:

* Normal Operation: The LED (pump) remains ON (Logic High, ~5 V) when the tank is empty or partially full.

* Emergency Stop: The LED turns OFF (Logic Low, ~0 V) immediately when both switch inputs are Logic High (simulating water detection).

* Validation: A specific Truth Table will be verified where only the input condition 1, 1 results in an output of 0.

Target audience: Basic level electronics students and hobbyists.

Materials

- V1: 5 V DC power supply, function: Main circuit power.

- U1: 74HC00, function: Quad 2-Input NAND Gate IC.

- S1: SPST Toggle Switch, function: High Level Sensor simulator.

- S2: SPST Toggle Switch, function: Safety Level Sensor simulator.

- R1: 10 kΩ resistor, function: Pull-down for S1.

- R2: 10 kΩ resistor, function: Pull-down for S2.

- R3: 330 Ω resistor, function: Current limiting for the Pump Status LED.

- D1: Green LED, function: Pump status indicator (ON = Running, OFF = Stopped).

Pin-out of the IC used

Chip: 74HC00 (Quad 2-Input NAND Gate)

| Pin | Name | Logic function | Connection in this case |

|---|---|---|---|

| 1 | 1 A | Input A | Connected to Sensor S1 |

| 2 | 1B | Input B | Connected to Sensor S2 |

| 3 | 1Y | Output Y | Connected to LED (Pump) |

| 7 | GND | Ground | Connected to 0 V |

| 14 | VCC | Power | Connected to 5 V |

Wiring guide

Construct the circuit following these node connections. Ensure the power supply is off while building.

- Power Rail: Connect V1 positive terminal to node

VCCand negative terminal to node0(GND). - IC Power: Connect U1 pin 14 to

VCCand pin 7 to0. - Sensor 1 (Input A):

- Connect S1 between

VCCand nodeSENSOR_HI. - Connect R1 between

SENSOR_HIand0(Pull-down). - Connect U1 pin 1 to node

SENSOR_HI.

- Connect S1 between

- Sensor 2 (Input B):

- Connect S2 between

VCCand nodeSENSOR_SAFE. - Connect R2 between

SENSOR_SAFEand0(Pull-down). - Connect U1 pin 2 to node

SENSOR_SAFE.

- Connect S2 between

- Pump Control (Output):

- Connect U1 pin 3 to node

PUMP_CTRL. - Connect D1 (Anode) to node

PUMP_CTRL. - Connect D1 (Cathode) to node

LED_NODE. - Connect R3 between

LED_NODEand0.

- Connect U1 pin 3 to node

Conceptual block diagram

Schematic

Title: Practical case: Water tank level control

INPUTS (Sensors) PROCESSING (U1: 74HC00) OUTPUT (Pump Indicator)

====================== =========================== ===========================

[ VCC ]

|

[ S1: High Sensor ]

|

+--(Node: SENSOR_HI)---------------> [ U1: Pin 1 (Input A) ]

| |

[ R1: 10k Pull-Down ] |

| v

[ GND ] [ NAND Gate ] --(Node: PUMP_CTRL)--> [ D1: Green LED ]

^ |

| (Node: LED_NODE)

[ VCC ] | |

| | [ R3: 330R ]

[ S2: Safe Sensor ] | |

| | [ GND ]

+--(Node: SENSOR_SAFE)-------------> [ U1: Pin 2 (Input B) ]

|

[ R2: 10k Pull-Down ]

|

[ GND ]

(Note: U1 Power Connections -> Pin 14: VCC, Pin 7: GND)

Truth table

The 74HC00 acts as a safety interlock. The pump runs (Output 1) by default and only stops (Output 0) when the specific danger condition (1, 1) is met.

| S1 (High Level) | S2 (Safety Level) | Voltage at Pin 3 | Pump Status (LED) | Logic State |

|---|---|---|---|---|

| 0 (Dry) | 0 (Dry) | High (~5 V) | ON | Safe |

| 0 (Dry) | 1 (Wet) | High (~5 V) | ON | Sensor Error/Safe |

| 1 (Wet) | 0 (Dry) | High (~5 V) | ON | Warning Level |

| 1 (Wet) | 1 (Wet) | Low (~0 V) | OFF | STOP (Danger) |

Measurements and tests

- Default State Check: Ensure S1 and S2 are open (OFF). Power on the circuit. Measure the voltage at node

PUMP_CTRLrelative to GND. It should read approximately 5 V. The Green LED should be lit. - Single Sensor Test: Close S1 only. The LED should remain ON. Open S1 and close S2 only. The LED should remain ON.

- Safety Stop Test: Close both S1 and S2 simultaneously.

- Measure the voltage at node

PUMP_CTRL. It should drop to near 0 V (< 0.1 V). - Confirm the LED turns OFF immediately.

- Measure the voltage at node

- Recovery: Open either switch; the LED should turn back ON.

SPICE netlist and simulation

Reference SPICE Netlist (ngspice) — excerptFull SPICE netlist (ngspice)

* Practical case: Water tank level control

.width out=256

* --- Models ---

* Generic Green LED Model

.model DLED D(IS=1e-14 N=2 RS=10 BV=5 IBV=10u CJO=10p)

* Ideal Voltage-Controlled Switch Model

.model SW_IDEAL sw(vt=2.5 vh=0 ron=1 roff=10Meg)

* --- Power Supply ---

* V1: 5 V DC power supply

V1 VCC 0 DC 5

* --- Input Sensors (Switches + Pull-downs) ---

* S1: High Level Sensor simulator

* Modeled as a switch connected to VCC, controlled by a pulse source (V_ACT1)

* Timing: Period 100us, covers logic states quickly

V_ACT1 ACT1 0 PULSE(0 5 0 1u 1u 50u 100u)

S1 VCC SENSOR_HI ACT1 0 SW_IDEAL

R1 SENSOR_HI 0 10k

* ... (truncated in public view) ...Copy this content into a .cir file and run with ngspice.

* Practical case: Water tank level control

.width out=256

* --- Models ---

* Generic Green LED Model

.model DLED D(IS=1e-14 N=2 RS=10 BV=5 IBV=10u CJO=10p)

* Ideal Voltage-Controlled Switch Model

.model SW_IDEAL sw(vt=2.5 vh=0 ron=1 roff=10Meg)

* --- Power Supply ---

* V1: 5 V DC power supply

V1 VCC 0 DC 5

* --- Input Sensors (Switches + Pull-downs) ---

* S1: High Level Sensor simulator

* Modeled as a switch connected to VCC, controlled by a pulse source (V_ACT1)

* Timing: Period 100us, covers logic states quickly

V_ACT1 ACT1 0 PULSE(0 5 0 1u 1u 50u 100u)

S1 VCC SENSOR_HI ACT1 0 SW_IDEAL

R1 SENSOR_HI 0 10k

* S2: Safety Level Sensor simulator

* Modeled as a switch connected to VCC, controlled by a pulse source (V_ACT2)

* Timing: Period 200us, provides different state combinations with S1

V_ACT2 ACT2 0 PULSE(0 5 0 1u 1u 100u 200u)

S2 VCC SENSOR_SAFE ACT2 0 SW_IDEAL

R2 SENSOR_SAFE 0 10k

* --- Logic IC: U1 (74HC00 Quad 2-Input NAND Gate) ---

* Wiring Guide connections:

* Pin 1 (Input A) -> SENSOR_HI

* Pin 2 (Input B) -> SENSOR_SAFE

* Pin 3 (Output) -> PUMP_CTRL

* Pin 7 (GND) -> 0

* Pin 14 (VCC) -> VCC

.subckt 74HC00 1 2 3 7 14

* Behavioral NAND implementation using continuous sigmoid functions for convergence

* V(3) = VCC * (1 - (Sigmoid(In1) * Sigmoid(In2)))

* Threshold is set to VCC/2 (approx 2.5V)

B_NAND 3 7 V = V(14) * (1 - ( (1/(1+exp(-50*(V(1)-0.5*V(14))))) * (1/(1+exp(-50*(V(2)-0.5*V(14))))) ))

.ends

XU1 SENSOR_HI SENSOR_SAFE PUMP_CTRL 0 VCC 74HC00

* --- Output Stage ---

* D1: Pump Status LED (Green)

* R3: Current limiting resistor

D1 PUMP_CTRL LED_NODE DLED

R3 LED_NODE 0 330

* --- Simulation Directives ---

.op

* Transient analysis for 500us to capture full truth table sequence

.tran 1u 500u

* --- Output Printing ---

* Required to generate simulation log

.print tran V(SENSOR_HI) V(SENSOR_SAFE) V(PUMP_CTRL) V(LED_NODE)Simulation Results (Transient Analysis)

Show raw data table (810 rows)

Index time v(sensor_hi) v(sensor_safe) v(pump_ctrl) v(led_node) 0 0.000000e+00 4.995005e-03 4.995005e-03 5.000000e+00 3.463208e+00 1 1.000000e-08 4.995005e-03 4.995005e-03 5.000000e+00 3.463209e+00 2 2.000000e-08 4.995005e-03 4.995005e-03 5.000000e+00 3.463209e+00 3 4.000000e-08 4.995005e-03 4.995005e-03 5.000000e+00 3.463209e+00 4 8.000000e-08 4.995005e-03 4.995005e-03 5.000000e+00 3.463209e+00 5 1.600000e-07 4.995005e-03 4.995005e-03 5.000000e+00 3.463209e+00 6 3.200000e-07 4.995005e-03 4.995005e-03 5.000000e+00 3.463209e+00 7 3.562500e-07 4.995005e-03 4.995005e-03 5.000000e+00 3.463209e+00 8 4.196875e-07 4.995005e-03 4.995005e-03 5.000000e+00 3.463209e+00 9 4.372461e-07 4.995005e-03 4.995005e-03 5.000000e+00 3.463209e+00 10 4.679736e-07 4.995005e-03 4.995005e-03 5.000000e+00 3.463209e+00 11 4.795524e-07 4.995005e-03 4.995005e-03 5.000000e+00 3.463209e+00 12 4.902290e-07 4.995005e-03 4.995005e-03 5.000000e+00 3.463209e+00 13 5.023412e-07 4.999500e+00 4.999500e+00 4.417025e-69 -7.81556e-01 14 5.138120e-07 4.999500e+00 4.999500e+00 4.417025e-69 1.002344e-01 15 5.170059e-07 4.999500e+00 4.999500e+00 4.417025e-69 3.466376e-02 16 5.182905e-07 4.999500e+00 4.999500e+00 4.417025e-69 2.349502e-02 17 5.201200e-07 4.999500e+00 4.999500e+00 4.417025e-69 1.345184e-02 18 5.222326e-07 4.999500e+00 4.999500e+00 4.417025e-69 7.036188e-03 19 5.244685e-07 4.999500e+00 4.999500e+00 4.417025e-69 3.539225e-03 20 5.268938e-07 4.999500e+00 4.999500e+00 4.417025e-69 1.673565e-03 21 5.291278e-07 4.999500e+00 4.999500e+00 4.417025e-69 8.446489e-04 22 5.313933e-07 4.999500e+00 4.999500e+00 4.417025e-69 4.221950e-04 23 5.337647e-07 4.999500e+00 4.999500e+00 4.417025e-69 2.037947e-04 ... (786 more rows) ...

Common mistakes and how to avoid them

- Floating Inputs: Forgetting R1 or R2 results in erratic switching because the CMOS inputs pick up electrical noise when switches are open. Fix: Always ensure inputs are pulled to Ground via resistors when the switch is open.

- LED Polarity: Connecting the LED backwards prevents it from lighting even when logic is High. Fix: Ensure the longer leg (Anode) faces the IC output pin.

- Shorting Output to Ground: Connecting Pin 3 directly to Ground to «test» it will damage the IC when it tries to output High. Fix: Always measure voltage with a multimeter in parallel, never force a node to ground with a wire.

Troubleshooting

- Symptom: LED is always ON, even when both switches are closed.

- Cause: Resistors R1/R2 might be connected to VCC instead of GND, or the IC is bypassed.

- Fix: Check that R1 and R2 connect to the negative rail (0) and switches connect to VCC.

- Symptom: LED never turns ON.

- Cause: LED reversed or R3 is too high value/open.

- Fix: Check D1 orientation and continuity of R3.

- Symptom: Circuit behaves erratically when touching wires.

- Cause: Floating inputs (Missing pull-down resistors).

- Fix: Verify R1 and R2 are securely connected to node

0.

Possible improvements and extensions

- Visual and Audible Alarm: Connect an additional active buzzer (via a transistor driver) to the output, but invert the signal first so the buzzer sounds when the pump stops.

- Motor Drive: Replace the LED with an NPN transistor (like 2N2222) and a relay to control a real DC water pump motor, adding a flyback diode for protection.

More Practical Cases on Prometeo.blog

Find this product and/or books on this topic on Amazon

As an Amazon Associate, I earn from qualifying purchases. If you buy through this link, you help keep this project running.