Level: Medium

Design a circuit that decreases LED backlight intensity as ambient light increases.

Objective and use case

In this practical case, you will build a PWM (Pulse Width Modulation) controller using a 555 timer and a photoresistor (LDR). The circuit will automatically adjust the duty cycle of the output signal based on ambient light levels, driving a power MOSFET to dim an LED strip.

Why it is useful:

* Energy Efficiency: Reduces power consumption in high-brightness environments where backlights might be less visible or needed (depending on display type).

* Automatic Night-Lights: Useful for systems that need to be dim during the day and bright at night (if logic is inverted) or vice-versa.

* Human Vision Comfort: Prevents glare by adjusting light intensity dynamically.

* Instrumentation: Often used in automotive dashboards or control panels.

Expected outcome:

* Signal Generation: A square wave output at pin 3 of the 555 timer.

* Inverse Response: When the LDR is exposed to strong light (Flashlight), the LED brightness decreases.

* Dark Response: When the LDR is covered (Darkness), the LED brightness increases to maximum.

* Target Audience: Intermediate electronics students and hobbyists.

Materials

- V1: 9 V DC voltage source, function: Main circuit power.

- R1: Photoresistor (LDR), function: Light sensor (Charge path).

- R2: 10 kΩ resistor, function: Discharge path timing.

- R3: 1 kΩ resistor, function: MOSFET Gate protection.

- R4: 330 Ω resistor, function: LED current limiting.

- C1: 100 nF capacitor, function: PWM timing capacitor.

- C2: 10 nF capacitor, function: Control voltage noise filtering.

- D1: 1N4148 diode, function: Steering diode for Charge path.

- D2: 1N4148 diode, function: Steering diode for Discharge path.

- D3: High-brightness White LED, function: Simulated Backlight.

- Q1: 2N7000 (N-Channel MOSFET), function: LED driver switch.

- U1: NE555 Precision Timer, function: PWM generator.

Wiring guide

This guide uses specific node names (VCC, 0, V_TRIG, V_GATE, etc.) to help you verify connections.

- Power Supply:

- Connect V1 positive terminal to node

VCC. - Connect V1 negative terminal to node

0(GND). - 555 Timer Power & Reset (U1):

- Connect U1 pin 8 (VCC) to node

VCC. - Connect U1 pin 1 (GND) to node

0. - Connect U1 pin 4 (Reset) to node

VCC. - Timing Network (The PWM Core):

- Connect R1 (LDR) between node

VCCand nodeV_CHARGE. - Connect D1 (Anode) to

V_CHARGEand D1 (Cathode) to nodeV_TIMING. - Connect D2 (Anode) to node

V_TIMINGand D2 (Cathode) to nodeV_DISCHARGE. - Connect R2 between node

V_DISCHARGEand U1 pin 7 (Discharge). - Connect C1 between node

V_TIMINGand node0. - Connect U1 pin 2 (Trigger) to node

V_TIMING. - Connect U1 pin 6 (Threshold) to node

V_TIMING. - Control Voltage:

- Connect C2 between U1 pin 5 (CV) and node

0. - Output Stage:

- Connect R3 between U1 pin 3 (Output) and node

V_GATE. - Connect Q1 Gate to node

V_GATE. - Connect Q1 Source to node

0. - Connect Q1 Drain to node

V_LED_CATHODE. - Load (Backlight):

- Connect R4 between node

VCCand nodeV_LED_ANODE. - Connect D3 Anode to node

V_LED_ANODE. - Connect D3 Cathode to node

V_LED_CATHODE.

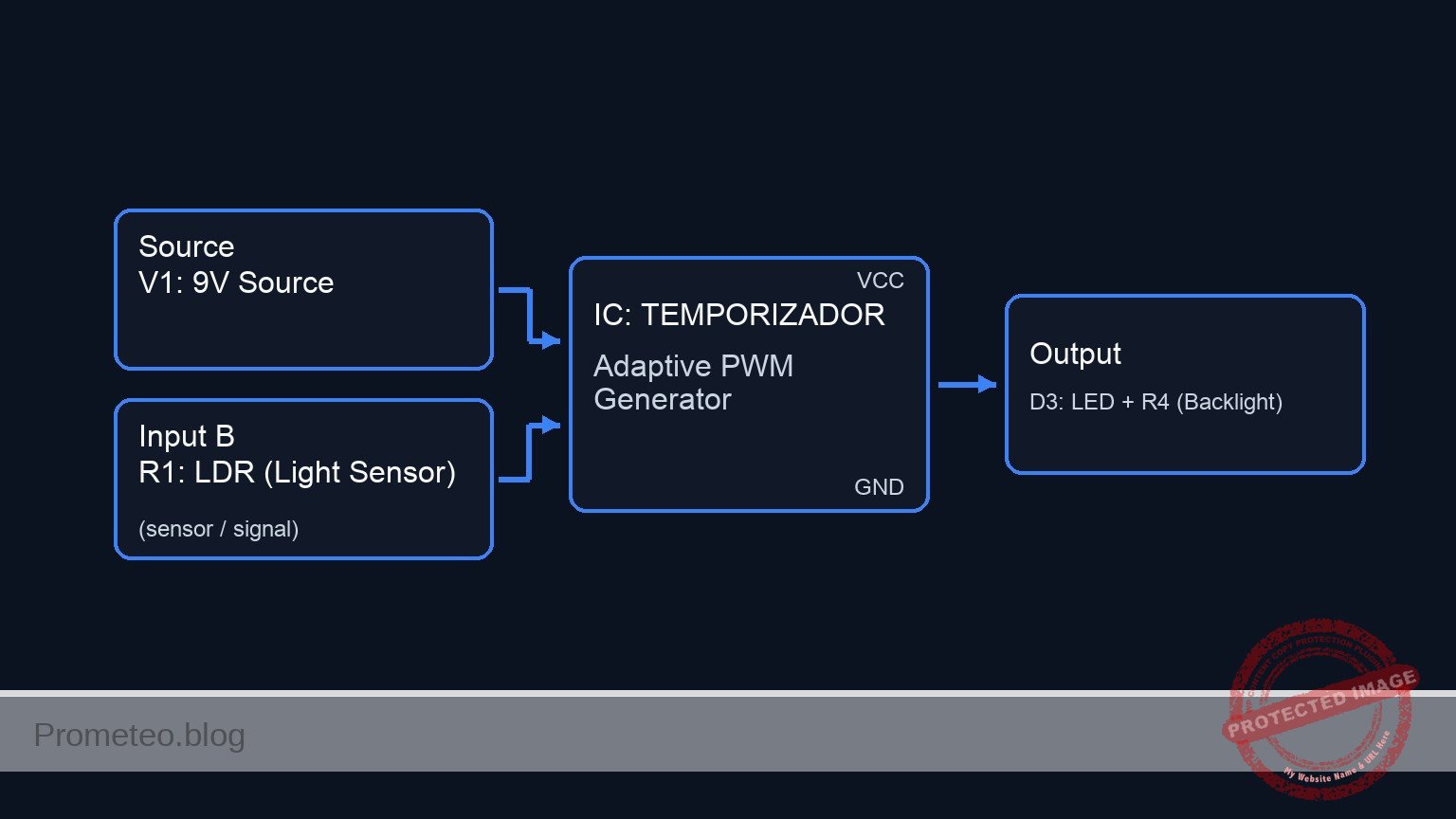

Conceptual block diagram

Schematic

Title: Practical case: Adaptive Screen Brightness Regulator

[ INPUTS / TIMING NETWORK ] [ LOGIC / CONTROL ] [ OUTPUT STAGE ]

[ V1: 9 V Source ] --(Power VCC)--------->+-----------------------+

| |

(Light) -> [ R1: LDR ] --(Charge)------->| |

| U1: NE555 |

[ D1, D2, R2 ] --(Steering/Disch)------->| (PWM Generator) |--(Pin 3)--> [ R3: 1k ] --> [ Q1: MOSFET ]

| | |

[ C1: 100nF ] --(Timing Ramp)----------->| Pins 2,6 (Trig/Thr) | |

| Pin 7 (Discharge) | (Switches GND)

[ C2: 10nF ] --(Filter)----------------->| Pin 5 (Ctrl Volt) | |

| | v

+-----------------------+ [ D3: LED + R4: 330R ]

(Backlight)

Measurements and tests

Perform these steps to validate the «Inverse» behavior (More light = Less Brightness).

- Baseline Check (Ambient Light):

- Power the circuit with 9 V.

- Observe the LED D3. It should be illuminated at a moderate level.

- Measure voltage at

V_GATEusing an oscilloscope. You should see a square wave.

- High Light Test:

- Shine a flashlight directly onto R1 (LDR).

- Observation: The LED D3 should dim significantly or turn off.

- Measurement: Check the duty cycle at

V_GATE. Since the LDR resistance drops, the capacitor charges very quickly (short Ton) relative to the fixed discharge time (Toff). The Duty Cycle (Ton / Ttotal) decreases.

- Low Light Test:

- Cover R1 (LDR) with your hand or a black cap.

- Observation: The LED D3 should reach maximum brightness.

- Measurement: The LDR resistance increases, making the charge time (Ton) much longer. The Duty Cycle increases towards 100%.

SPICE netlist and simulation

Reference SPICE Netlist (ngspice) — excerptFull SPICE netlist (ngspice)

* Practical case: Adaptive Screen Brightness Regulator

* --- Power Supply ---

V1 VCC 0 DC 9

* --- Input Stage (Light Sensor) ---

R1 VCC V_CHARGE 20k

* --- PWM Timing Network ---

D1 V_CHARGE V_TIMING D1N4148

D2 V_TIMING V_DISCHARGE D1N4148

R2 V_DISCHARGE V_DISCH_PIN 10k

C1 V_TIMING 0 100n

* --- Control & Processing ---

* U1: NE555 Precision Timer

XU1 0 V_TIMING V_OUT_PIN VCC V_CV V_TIMING V_DISCH_PIN VCC NE555

* Control Voltage noise filtering

C2 V_CV 0 10n

* ... (truncated in public view) ...Copy this content into a .cir file and run with ngspice.

* Practical case: Adaptive Screen Brightness Regulator

* --- Power Supply ---

V1 VCC 0 DC 9

* --- Input Stage (Light Sensor) ---

R1 VCC V_CHARGE 20k

* --- PWM Timing Network ---

D1 V_CHARGE V_TIMING D1N4148

D2 V_TIMING V_DISCHARGE D1N4148

R2 V_DISCHARGE V_DISCH_PIN 10k

C1 V_TIMING 0 100n

* --- Control & Processing ---

* U1: NE555 Precision Timer

XU1 0 V_TIMING V_OUT_PIN VCC V_CV V_TIMING V_DISCH_PIN VCC NE555

* Control Voltage noise filtering

C2 V_CV 0 10n

* --- Output Driver Stage ---

R3 V_OUT_PIN V_GATE 1k

* Q1: N-Channel MOSFET

MQ1 V_LED_CATHODE V_GATE 0 0 2N7000

* --- Load (Backlight) ---

R4 VCC V_LED_ANODE 330

D3 V_LED_ANODE V_LED_CATHODE WHITE_LED

* --- Component Models ---

.model D1N4148 D (IS=2.682n N=1.836 RS=.5664 BV=100 IBV=100p CJO=4p TT=11.54n)

.model 2N7000 NMOS (Level=1 VTO=2.1 KP=0.5 Lambda=0.002 RD=1.5 RS=1.5 CGSO=10p CGDO=10p CGBO=10p)

.model WHITE_LED D (IS=1p N=5 RS=5 BV=5 IBV=10u CJO=50p)

* --- NE555 Behavioral Subcircuit ---

.subckt NE555 GND TRIG OUT RESET CV THRES DISCH VCC

* Internal Voltage Divider

R_div1 VCC CV 5k

R_div2 CV TR 5k

R_div3 TR GND 5k

* Comparators (Sigmoid-based for smooth convergence)

* Set Signal (Active High) when TRIG < 1/3 VCC (V_TR)

B_set set_node 0 V = 2.5 + 2.5 * tanh(100 * (V(TR) - V(TRIG)))

* Reset Signal Logic

* Condition 1: THRES > CV

B_c1 c1 0 V = 0.5 * (1 + tanh(100 * (V(THRES) - V(CV))))

* Condition 2: RESET < 1.0V

B_c2 c2 0 V = 0.5 * (1 + tanh(100 * (1.0 - V(RESET))))

* Combine (Probabilistic OR logic): V_rst = c1 + c2 - c1*c2, scaled to 5V

B_rst rst_node 0 V = 5 * (V(c1) + V(c2) - V(c1)*V(c2))

* RC Delays to prevent algebraic loops in Flip-Flop

R_sd set_node set_d 1k

C_sd set_d 0 1p

R_rd rst_node rst_d 1k

C_rd rst_d 0 1p

* SR Latch (Cross-coupled NOR logic with soft thresholds)

* Q = ~(R | Qb)

B_q q_int 0 V = 5 / (1 + exp( 20 * (V(rst_d) + V(qb_int) - 2.5) ))

* Qb = ~(S | Q)

B_qb qb_int 0 V = 5 / (1 + exp( 20 * (V(set_d) + V(q_int) - 2.5) ))

* Output Buffer

E_out OUT_int 0 q_int 0 1

R_out_prot OUT_int OUT 1

* Discharge Transistor (Switch to GND when Qb is High / Output Low)

S_disch DISCH 0 qb_int 0 SW_DISCH

.model SW_DISCH SW(Vt=2.5 Ron=10 Roff=100Meg)

.ends

* --- Simulation Directives ---

.tran 10u 20m

.print tran V(V_TIMING) V(V_GATE) V(V_LED_CATHODE) V(V_LED_ANODE)

.op

.endSimulation Results (Transient Analysis)

Show raw data table (4016 rows)

Index time v(v_timing) v(v_gate) v(v_led_cathode 0 0.000000e+00 3.183820e+00 9.643749e-22 8.709822e+00 1 1.000000e-07 3.183820e+00 9.643749e-22 8.709822e+00 2 2.000000e-07 3.183820e+00 -2.54330e-17 8.709822e+00 3 4.000000e-07 3.183820e+00 4.759196e-18 8.709822e+00 4 8.000000e-07 3.183820e+00 -5.90561e-18 8.709822e+00 5 1.600000e-06 3.183820e+00 1.843922e-17 8.709822e+00 6 3.200000e-06 3.183820e+00 4.911091e-18 8.709822e+00 7 6.400000e-06 3.183819e+00 9.652751e-18 8.709822e+00 8 1.280000e-05 3.183819e+00 -2.42211e-18 8.709822e+00 9 2.280000e-05 3.183818e+00 -2.25892e-17 8.709822e+00 10 3.280000e-05 3.183818e+00 -5.29878e-18 8.709822e+00 11 4.280000e-05 3.183817e+00 -8.38426e-18 8.709822e+00 12 5.280000e-05 3.183816e+00 -5.24090e-18 8.709822e+00 13 6.280000e-05 3.183815e+00 5.344924e-18 8.709822e+00 14 7.280000e-05 3.183815e+00 -6.20163e-18 8.709822e+00 15 8.280000e-05 3.183814e+00 -2.95146e-18 8.709822e+00 16 9.280000e-05 3.183813e+00 -1.95605e-17 8.709822e+00 17 1.028000e-04 3.183813e+00 5.833300e-18 8.709822e+00 18 1.128000e-04 3.183812e+00 -9.79628e-18 8.709822e+00 19 1.228000e-04 3.183812e+00 1.090495e-18 8.709822e+00 20 1.328000e-04 3.183811e+00 -1.79618e-17 8.709822e+00 21 1.428000e-04 3.183810e+00 6.632650e-18 8.709822e+00 22 1.528000e-04 3.183810e+00 -1.47697e-17 8.709822e+00 23 1.628000e-04 3.183809e+00 6.958764e-18 8.709822e+00 ... (3992 more rows) ...

Common mistakes and how to avoid them

- Reversing Steering Diodes (D1, D2):

- Error: Placing D1 or D2 backwards prevents the capacitor from charging or discharging properly.

- Solution: Ensure the black band (cathode) of D1 points towards the capacitor and the black band of D2 points towards Pin 7.

- Connecting LDR to Pin 7 directly:

- Error: Connecting the LDR without the steering diodes creates a standard astable oscillator where frequency changes drastically, but duty cycle control is less distinct.

- Solution: Use the diode steering topology described to separate the Charge (LDR) and Discharge (R2) paths.

- MOSFET Pinout Confusion:

- Error: Swapping Drain and Source on the 2N7000.

- Solution: Verify the datasheet. For 2N7000 (TO-92), looking at the flat side, pins are usually Source, Gate, Drain (left to right).

Troubleshooting

- Symptom: LED is always ON and does not change with light.

- Cause: MOSFET Gate floating or Pin 3 stuck High.

- Fix: Check R1 and C1 connections. Ensure Pin 2 and 6 are tied together.

- Symptom: LED is always OFF.

- Cause: LDR resistance is too low (short circuit) or LED connected backwards.

- Fix: Check LED polarity. Measure resistance of LDR in darkness; if it is 0 Ω, it is defective.

- Symptom: LED flickers visibly.

- Cause: Frequency is too low.

- Fix: Reduce the value of C1 (e.g., change from 100 nF to 10 nF) to increase the PWM frequency beyond human persistence of vision (> 100 Hz).

Possible improvements and extensions

- Minimum Brightness Clamp: Add a fixed resistor in series with the LDR (R1). This ensures that even in extremely bright light (low LDR resistance), there is still a minimum charge time, preventing the LED from turning off completely.

- Smoother Transition: Add a large capacitor across the LDR to filter out rapid changes in light (e.g., shadows from passing objects), creating a «fade» effect rather than an instant jump in brightness.

More Practical Cases on Prometeo.blog

Find this product and/or books on this topic on Amazon

As an Amazon Associate, I earn from qualifying purchases. If you buy through this link, you help keep this project running.